Heat exchange tube and evaporator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

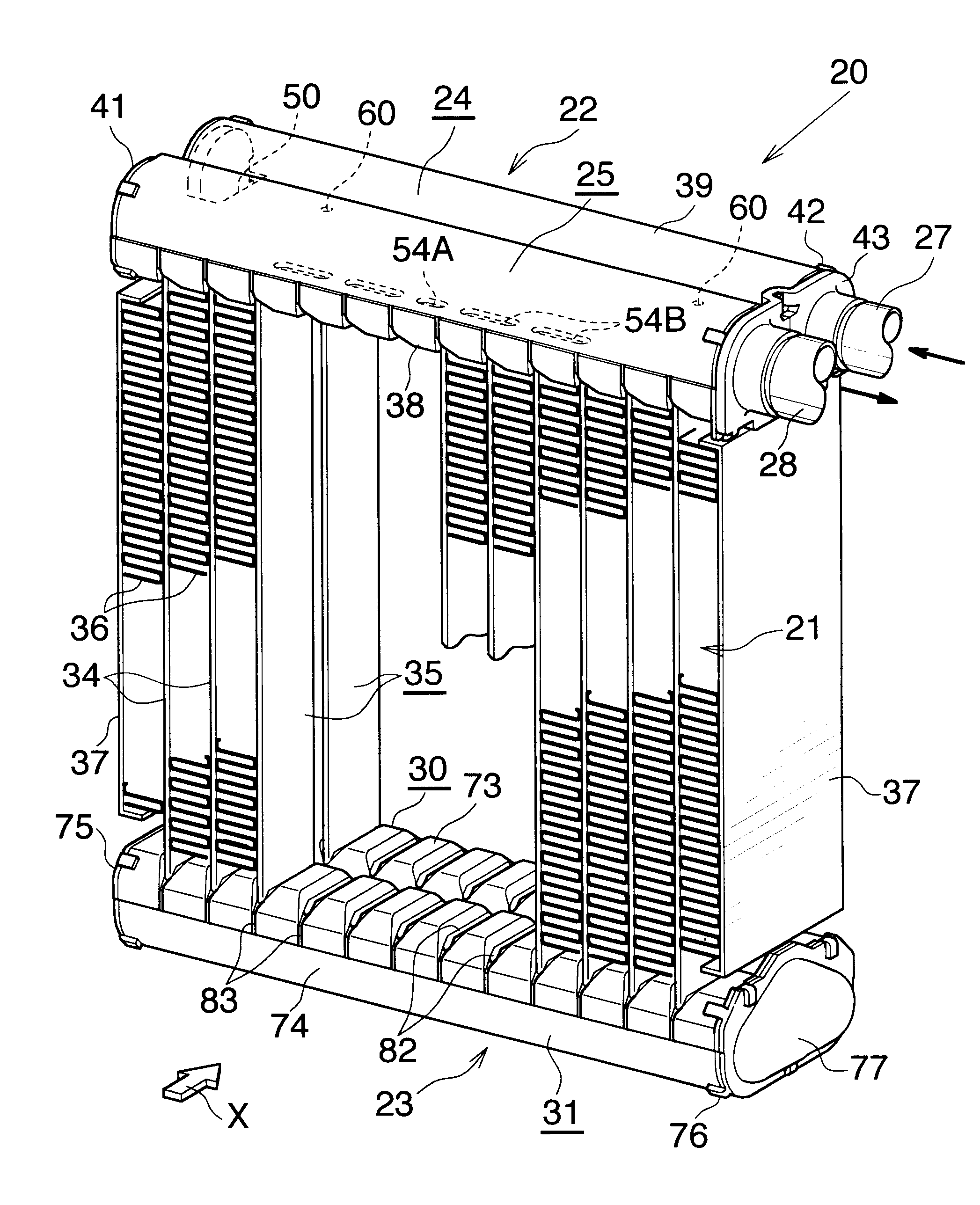

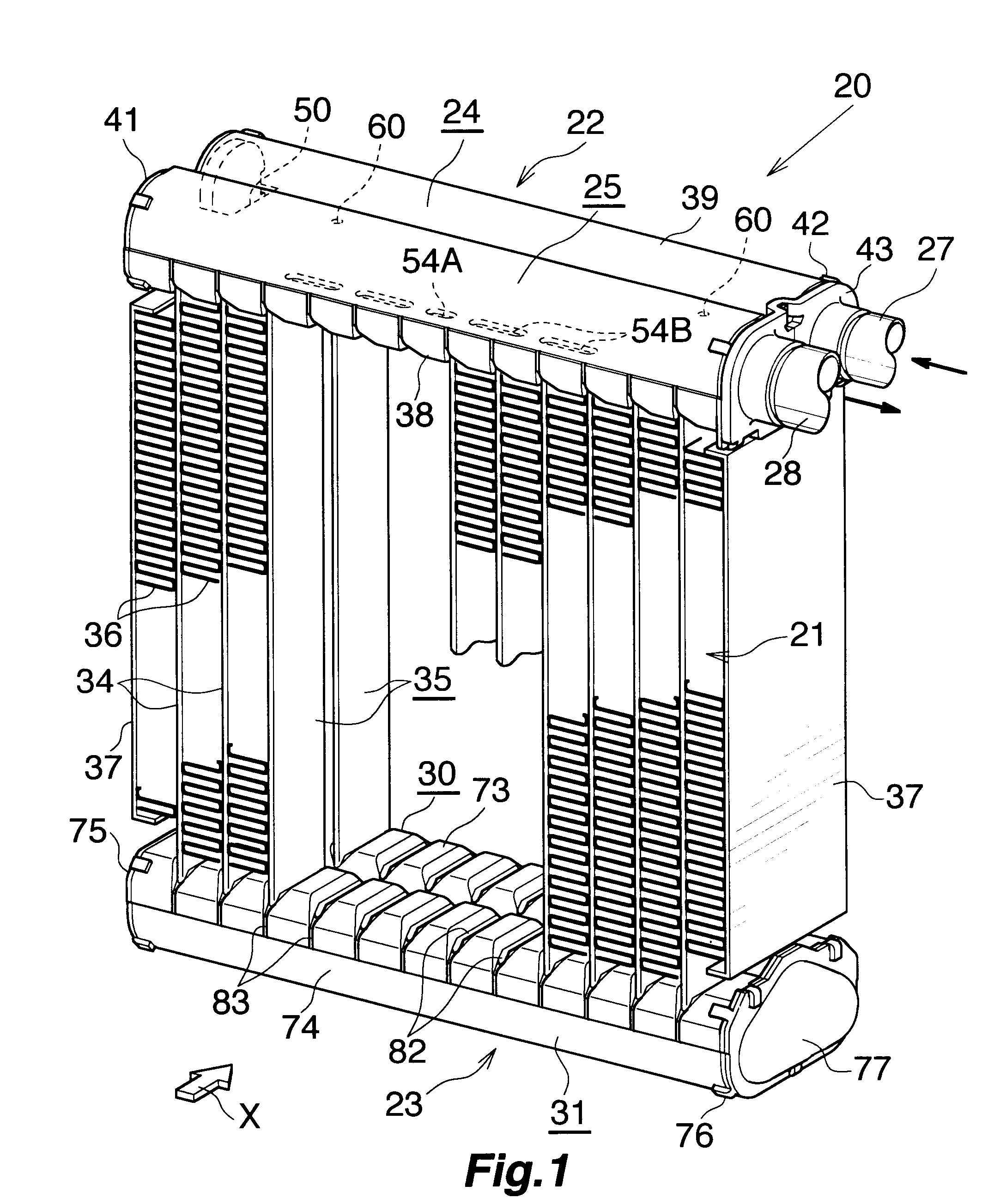

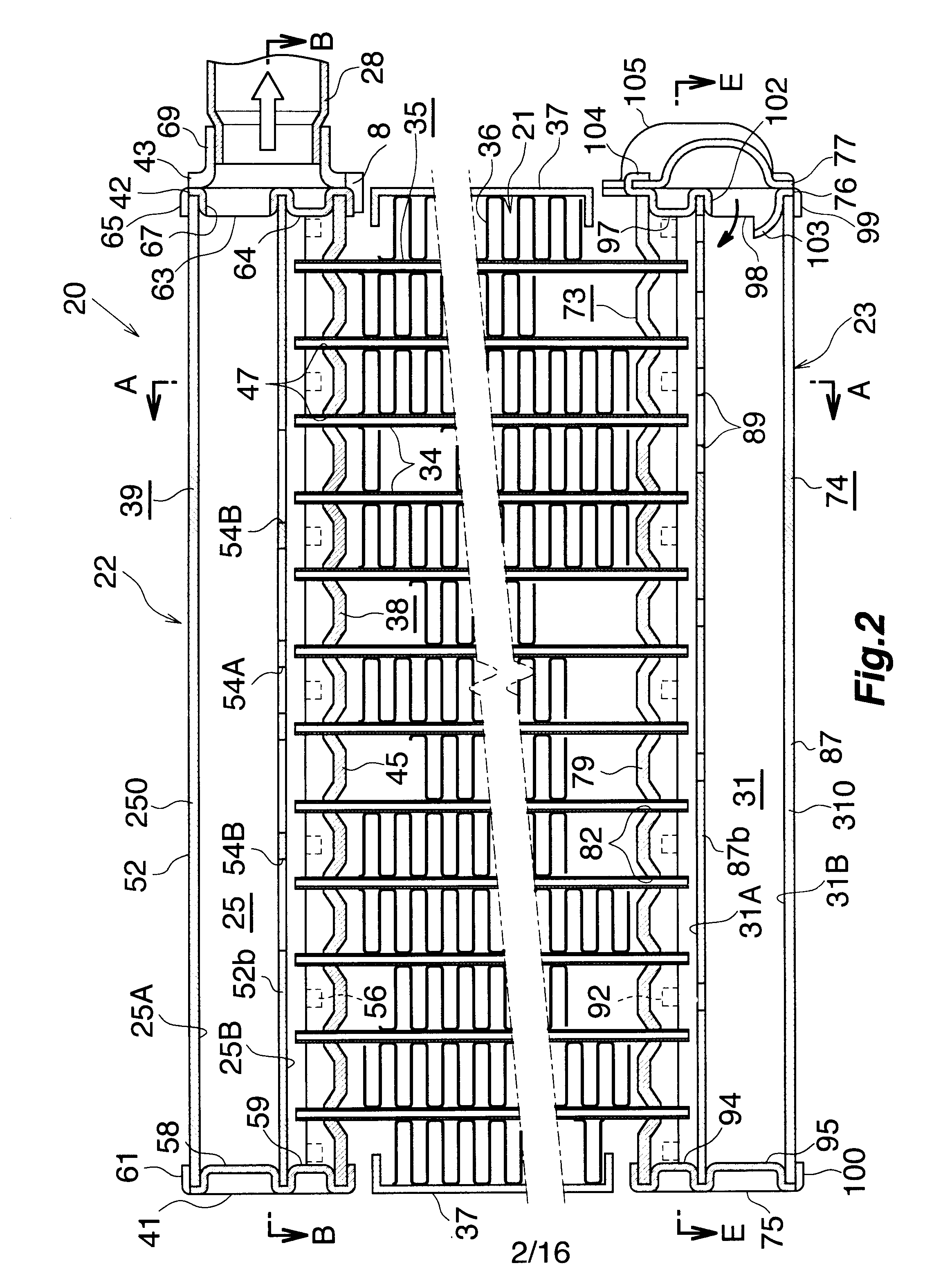

[0102]The evaporator 20 was prepared which employed the heat exchange tubes 34 each having the configuration shown in FIG. 4; i.e., the number of the refrigerant channels 34a is 11, and the number of the protrusions 346 on the inner peripheral surface of each of the refrigerant channels 34a excluding the opposite-end refrigerant channels 34a is 4.

example 2

[0103]An evaporator was prepared which employed heat exchange tubes 34A each having the configuration shown in FIG. 13a; i.e., the number of the refrigerant channels 34a is 14, and the number of the protrusions 346 on the inner peripheral surface of each of the refrigerant channels 34a excluding the opposite-end refrigerant channels 34a is 4.

example 3

[0104]An evaporator was prepared which employed heat exchange tubes 34B each having the configuration shown in FIG. 13b; i.e., the number of the refrigerant channels 34a is 16, and the number of the protrusions 346 on the inner peripheral surface of each of the refrigerant channels 34a excluding the opposite-end refrigerant channels 34a is 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com