Concentric tube heat exchanger end seal therefor

a technology of heat exchanger and end seal, which is applied in the direction of heat exchanger sealing arrangement, indirect heat exchanger, light and heating apparatus, etc., can solve the problems of significant increase in weight and cost of heat exchanger, and the difficulty of sealing the annular passageway by tube deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

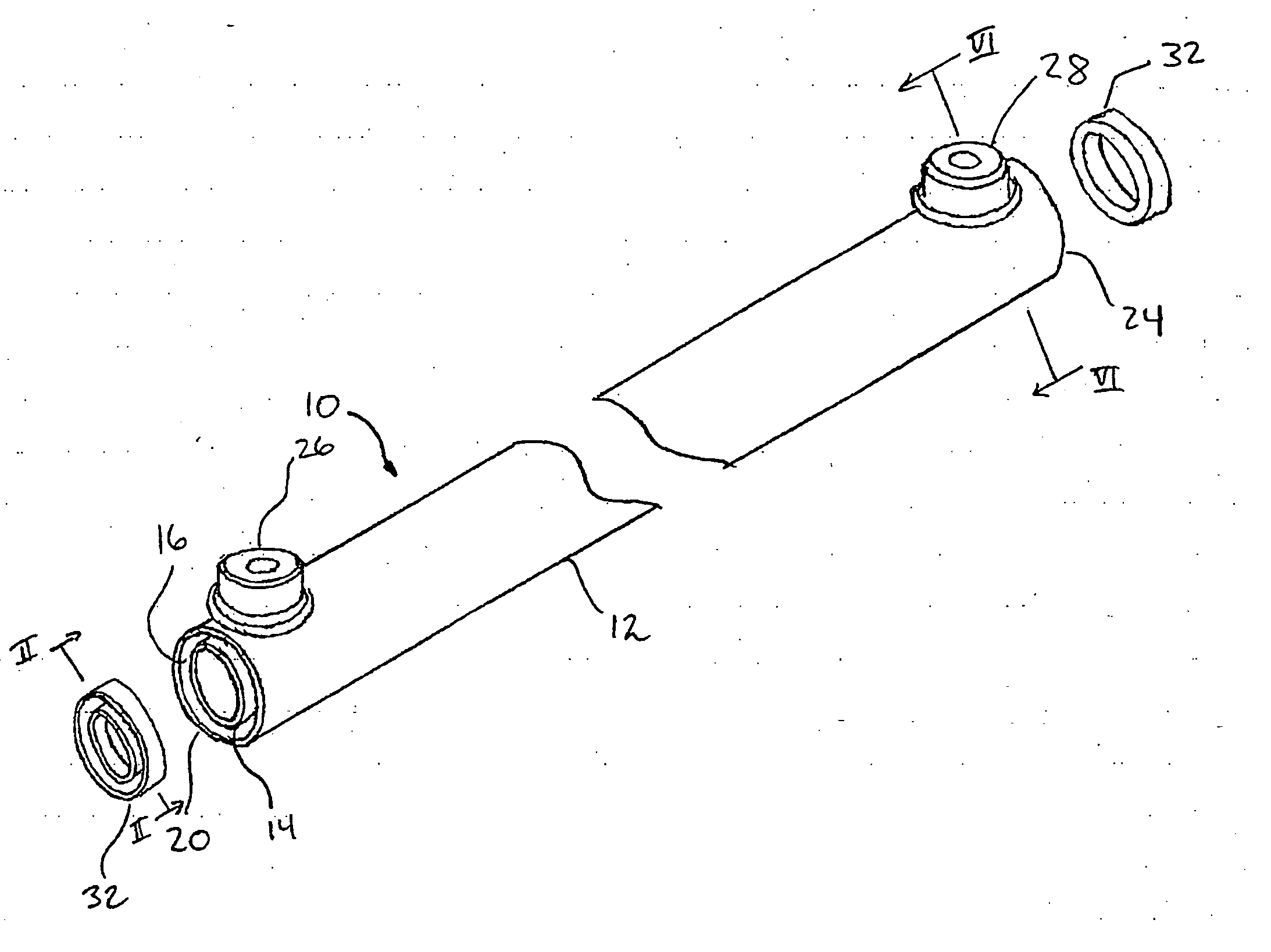

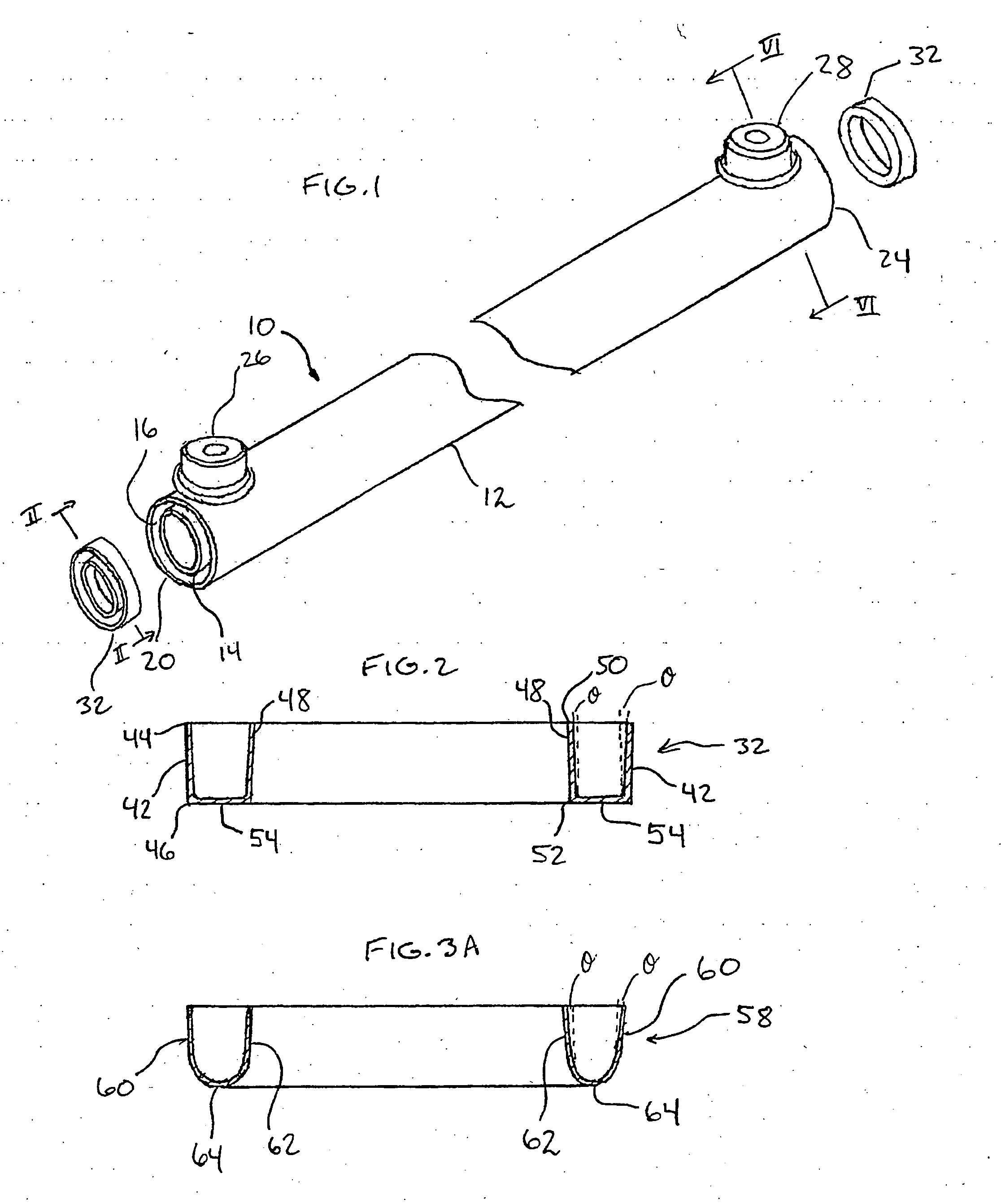

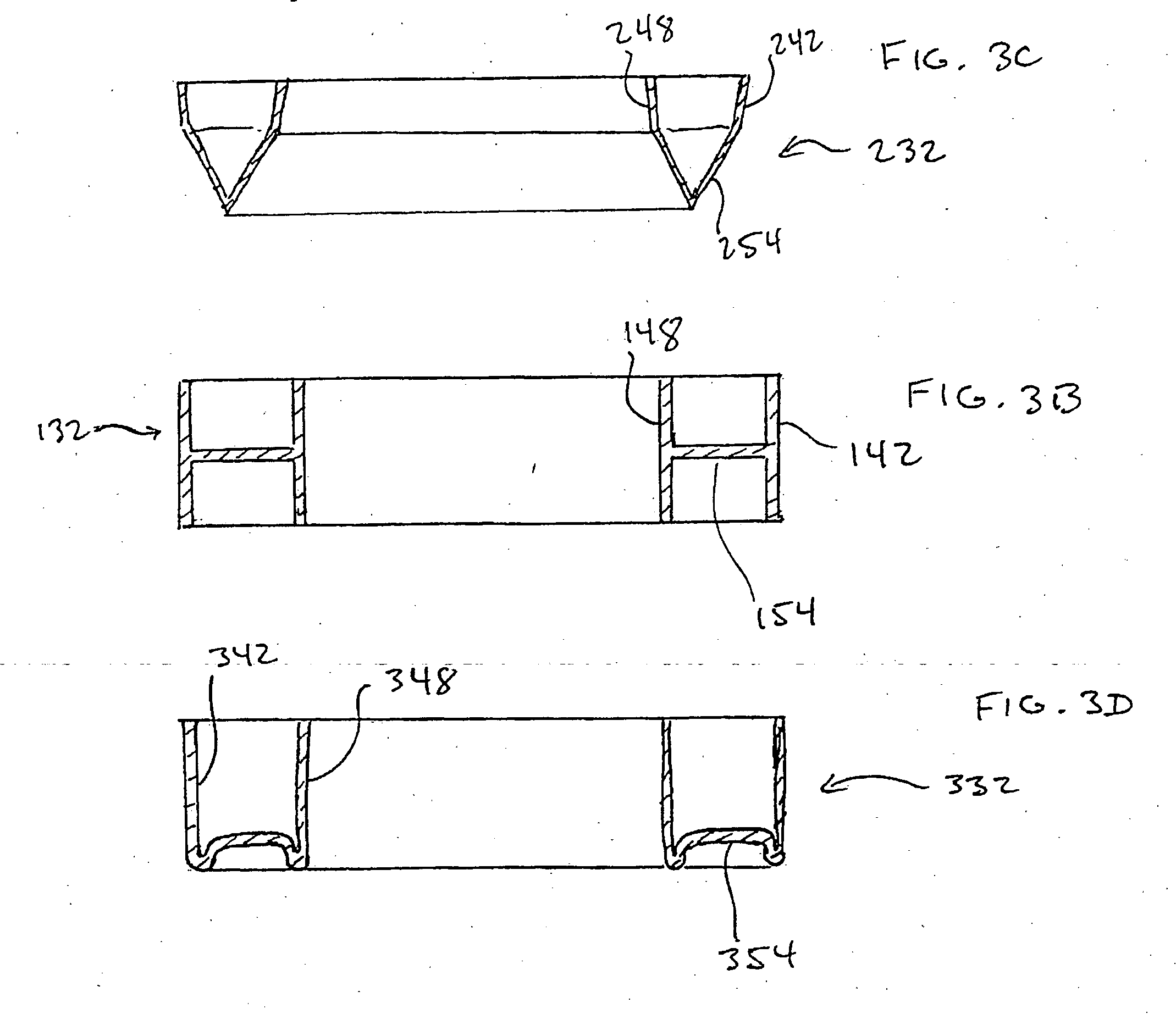

[0018]FIG. 1 illustrates a preferred concentric tube heat exchanger 10 according to the invention. Heat exchanger 10 comprises an outer cylindrical tube 12 and an inner cylindrical tube 14, the inner tube 14 being received in the outer tube 12 and concentric therewith, with an annular passageway 16 being formed between the outer and inner tubes 12, 14 and extending through substantially the entire length of the heat exchanger 10.

[0019] Heat exchanger 10 further comprises an inlet port 18 located adjacent its first end 20 and an outlet port 22 (FIG. 6) located adjacent its second end 24. Both the inlet and outlet ports 18, 22 comprise perforations formed in the outer tube 12 through which a fluid to be cooled, such as oil, is allowed to enter and exit the annular passageway 16. The heat exchanger 10 further comprises an inlet filting 26 and an outlet filting 28 which are mounted to the outer surface of the outer tube 12 in communication with the inlet and outlet ports 18, 22 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com