Gas steam combined cycle central heating device and heating method

一种燃气蒸汽、联合循环的技术,应用在蒸汽机装置、热水集中供暖系统、加热方式等方向,能够解决污染物排放、供热效率低、供热安全性影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

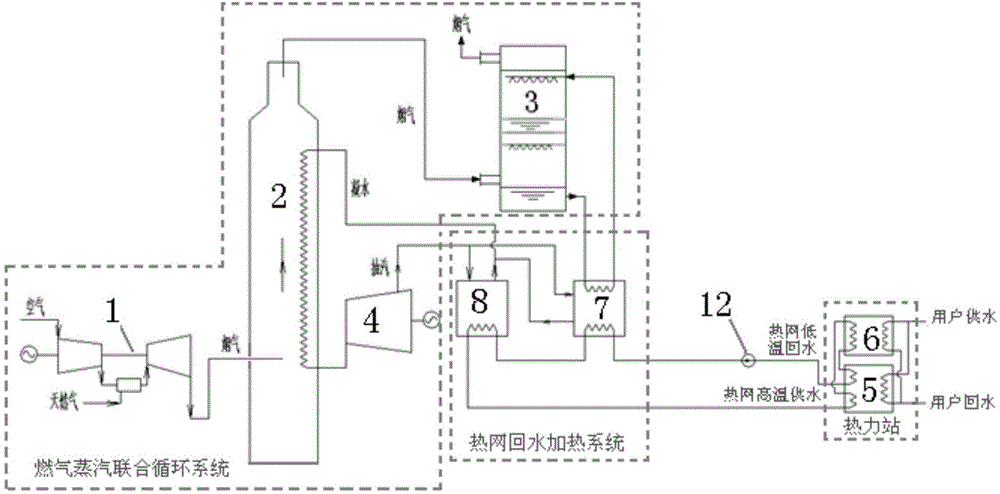

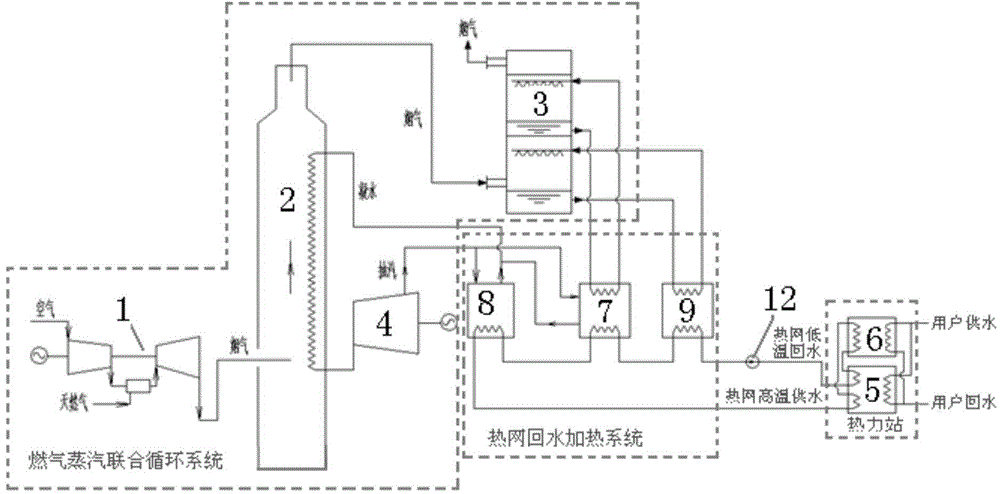

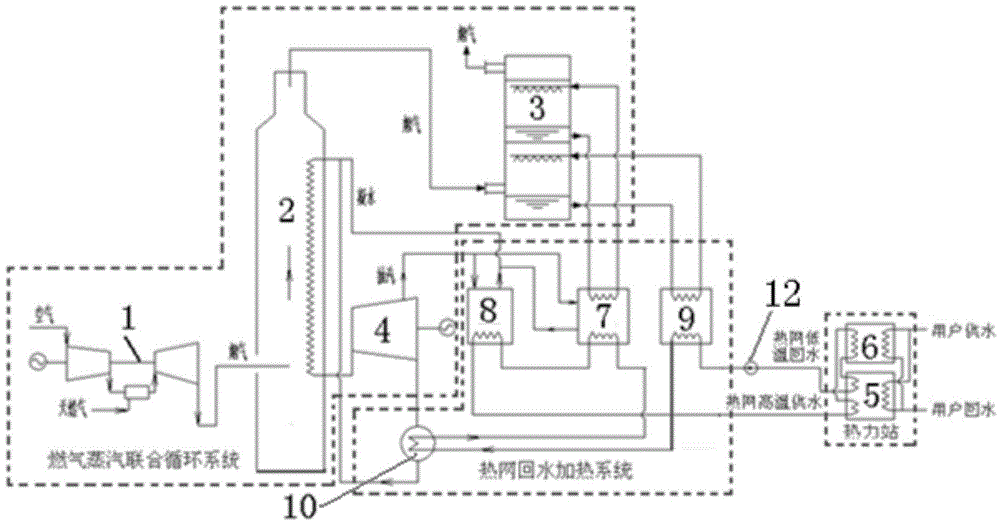

[0030] Such as figure 1 As shown, the present invention provides a gas-steam combined cycle central heating device, which includes a gas-steam combined cycle system, a thermal station and a heating network return water heating system; connect.

[0031] The gas-steam combined cycle system includes a gas turbine 1, a waste heat boiler 2, a direct contact flue gas condensation heat exchanger 3 and a steam turbine 4. The exhaust port of the gas turbine 1 is connected to the flue gas inlet of the waste heat boiler 2 . The flue gas outlet of the waste heat boiler 2 is connected to the flue gas inlet of the direct contact flue gas condensing heat exchanger 3, the exhaust steam outlet of the waste heat boiler 2 is connected to the steam inlet of the steam turbine 4, and the drain inlet of the waste heat boiler 2 is connected to the heat network backwater he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com