Particulate matter trap filter regeneration temperature control for internal combustion engine

a technology of internal combustion engine and regeneration temperature control, which is applied in the direction of electric control, machines/engines, mechanical equipment, etc., can solve the problems of difficult filter regeneration and adversely affect the fuel consumption of the engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

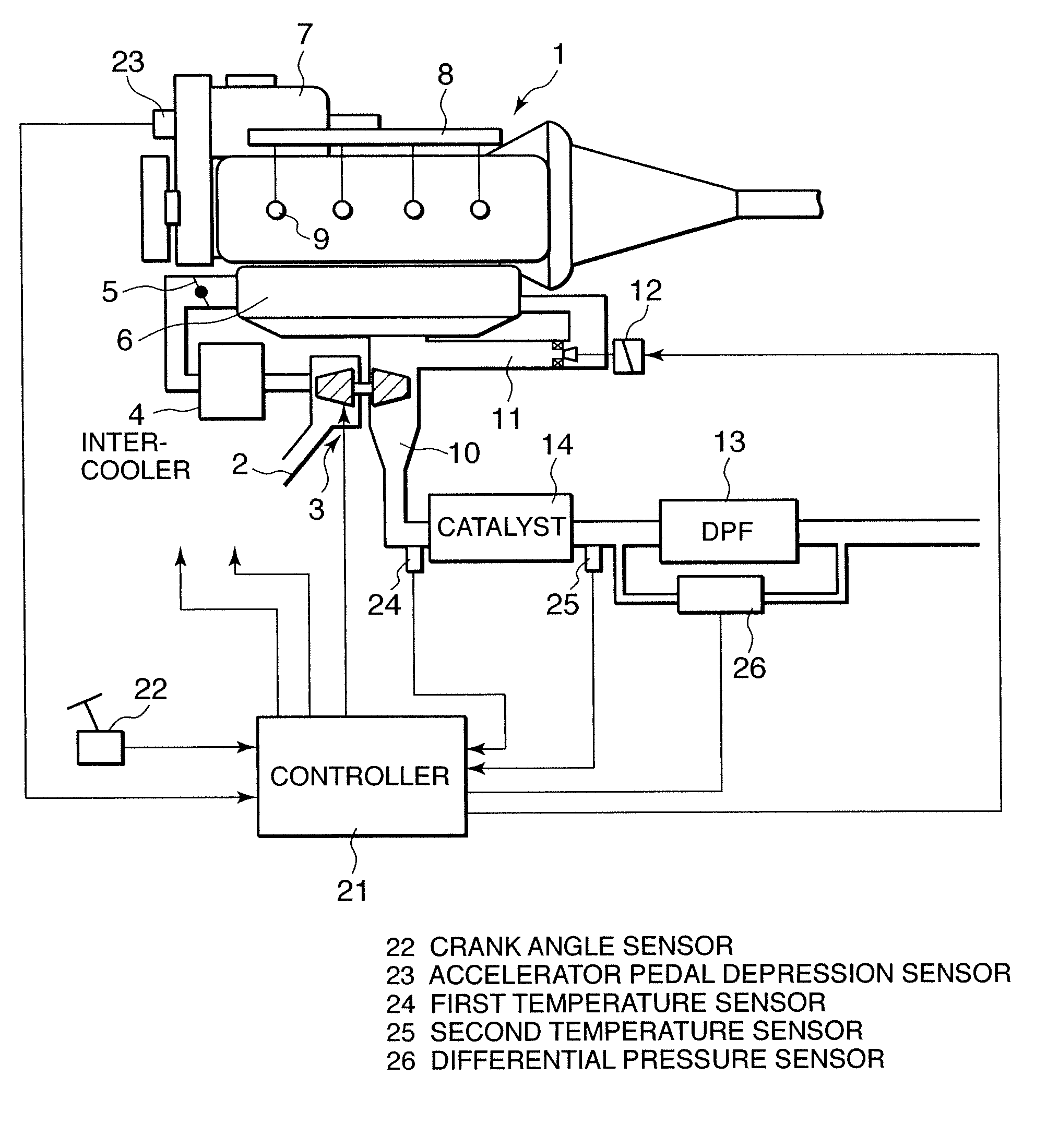

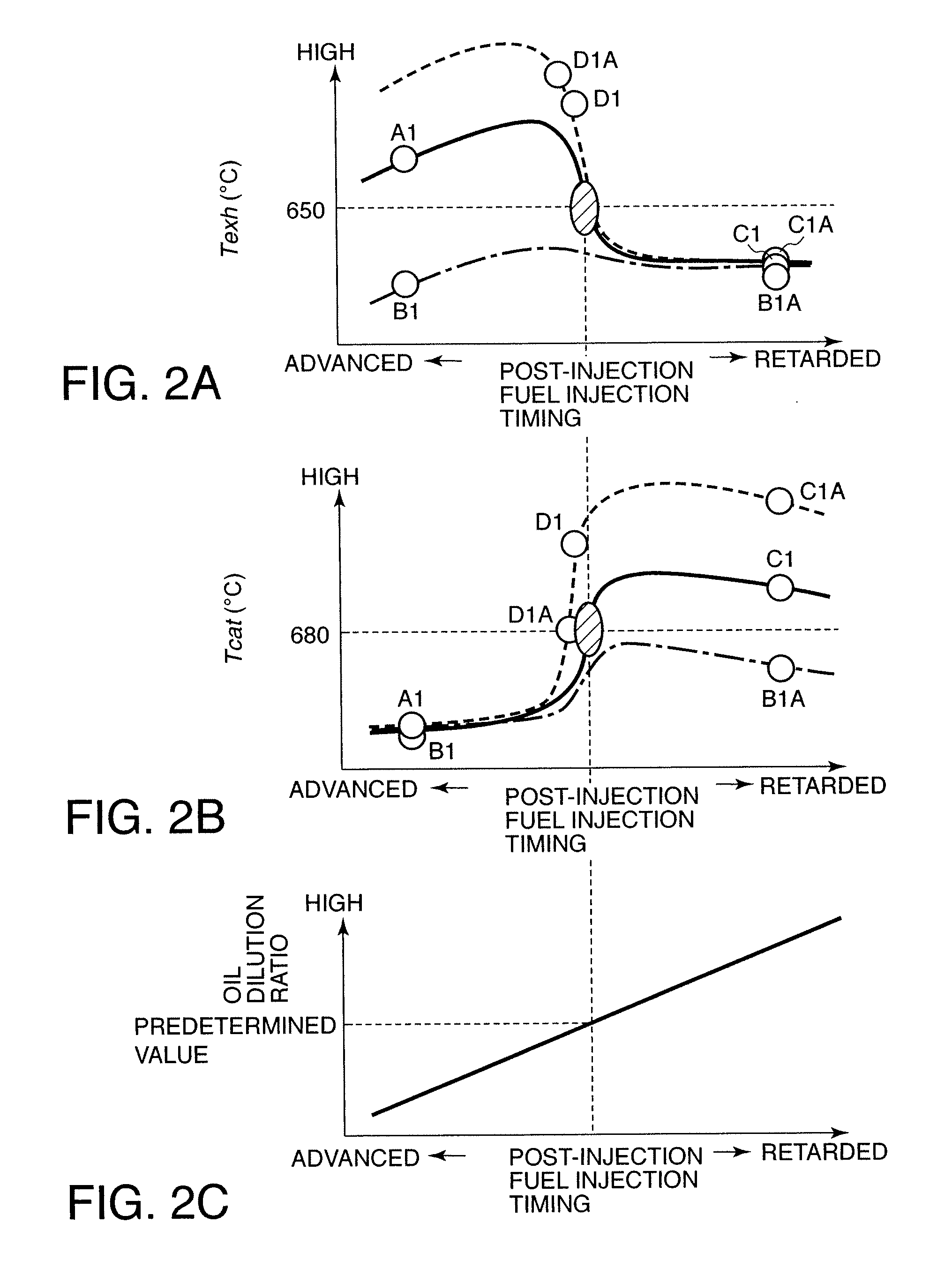

[0019]Referring to FIG. 1 of the drawings, a multi-cylinder diesel engine 1 for a vehicle comprises an intake passage 2 in which a compressor of a variable nozzle turbocharger 3, an inter-cooler 4, and an intake throttle 5 are installed. Intake air of the diesel engine 1 is turbocharged by the compressor of the turbocharger 3, cooled by the inter-cooler 4, and, after being subjected to flow rate regulation by the intake throttle 5, supplied to a combustion chamber formed in each cylinder of the diesel engine 1 via an intake collector 6.

[0020]The diesel engine 1 comprises a common-rail type fuel injection device. The common-rail type fuel injection device comprises a high-pressure fuel pump 7, a common-rail 8, and a fuel injector 9 disposed in each cylinder. The high-pressure fuel pump 7 pressurizes fuel and supplies it to the common-rail 8, and the fuel injector 9 injects the fuel stored in the common-rail 8 directly into the combustion chamber in each cylinder.

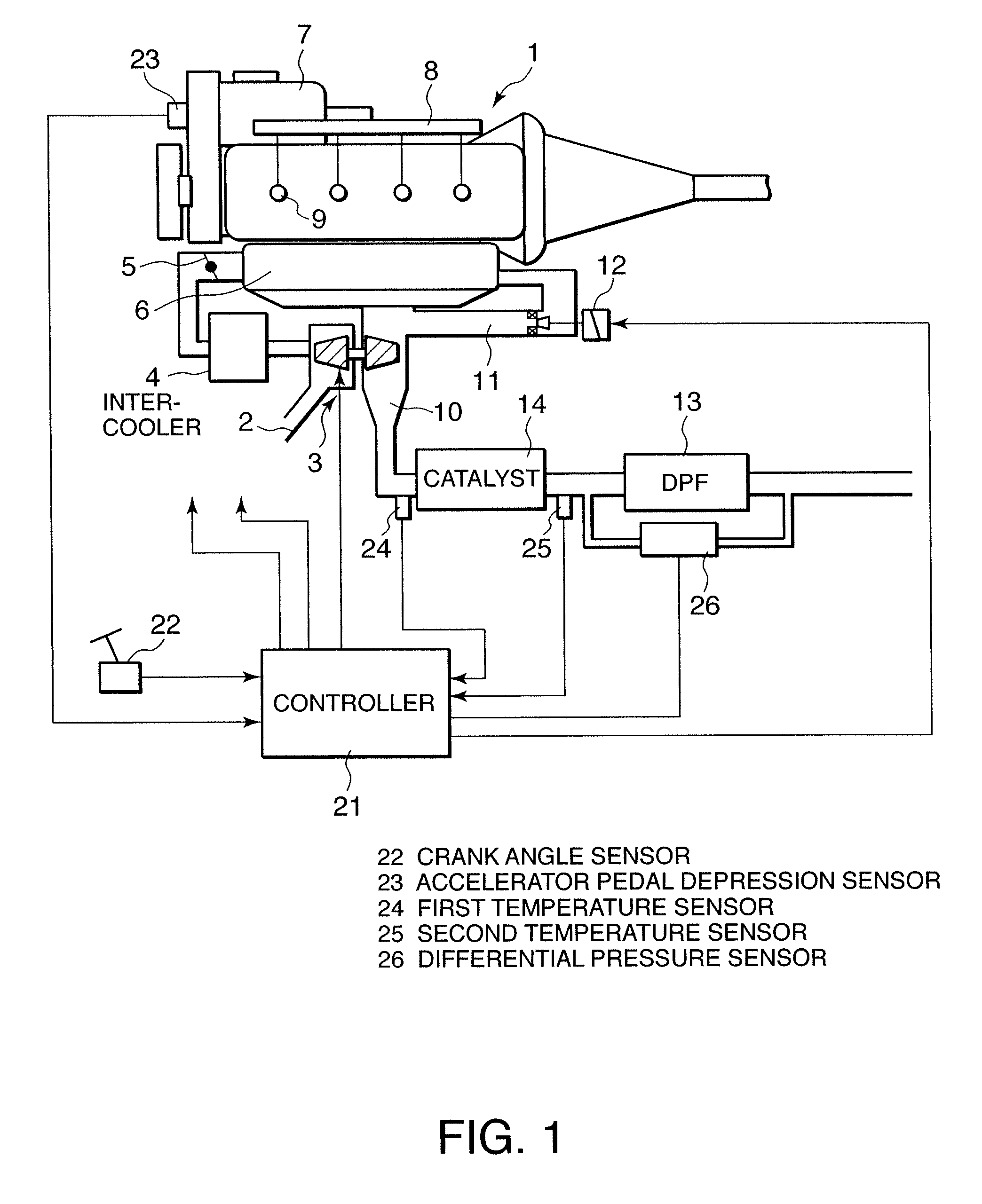

[0021]An air-fuel mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com