Gas-fired boiler afterheat recovering system and recovering method

A waste heat recovery system and a technology for gas boilers, which are applied in the field of boiler waste heat recovery, can solve the problems of heat waste, non-condensation of water vapor, large smoke exhaust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

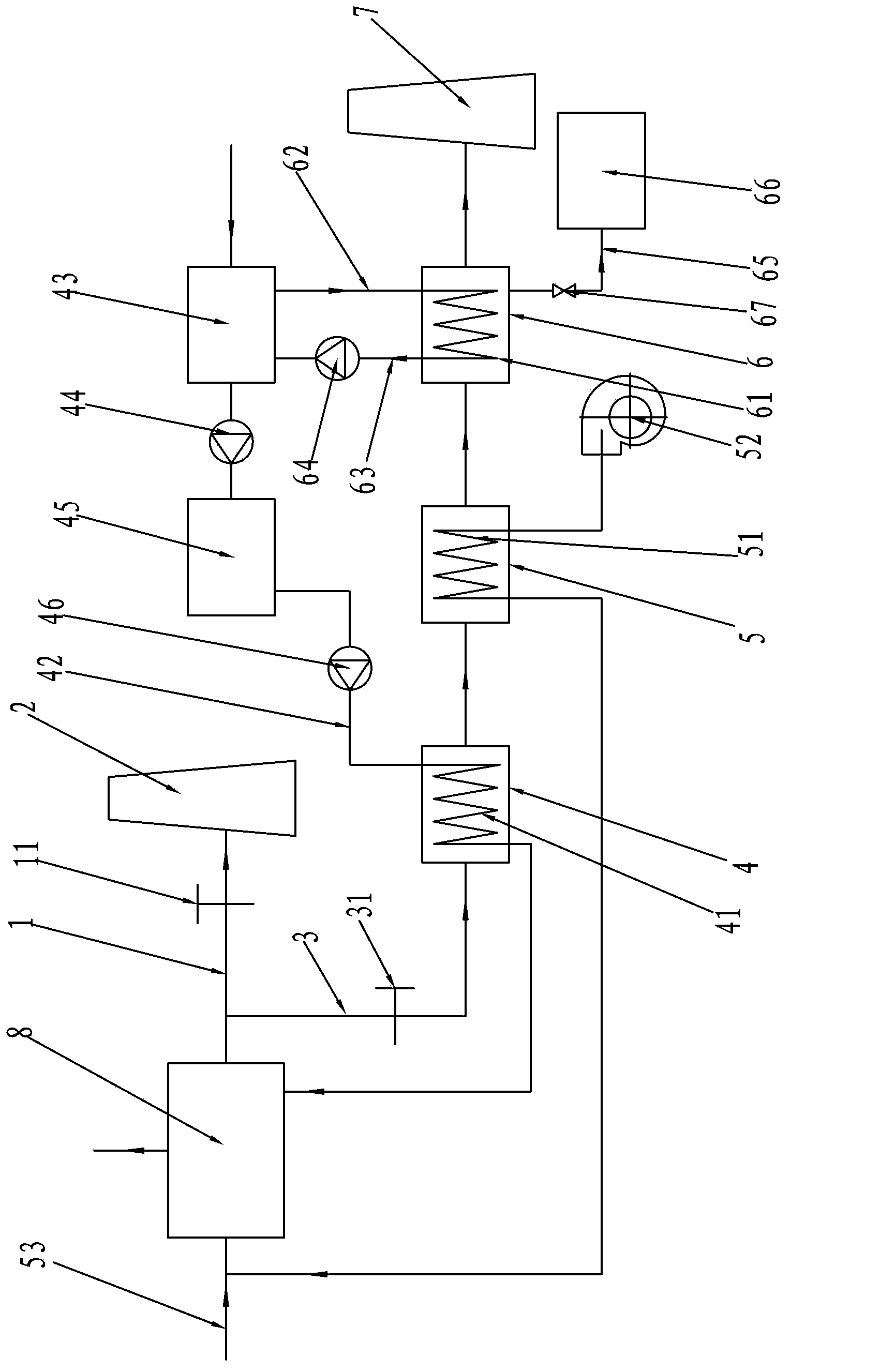

[0022] like figure 1 As shown, the gas boiler waste heat recovery system of the present invention includes a main flue 1, a main chimney 2, a bypass flue 3, a boiler economizer 4, an air preheater 5, a condensing heat exchanger 6, and a bypass chimney 7, One end of the main flue 1 is connected to the exhaust port of the boiler, and the other end is connected to the main chimney 2. A flue butterfly valve 11 is installed on the main flue 1, and a bypass flue 3 is connected in parallel to the main flue 1 in front of the flue butterfly valve 11. A bypass flue butterfly valve 31 , a boiler economizer 4 , an air preheater 5 , and a condensing heat exchanger 6 are connected in series on the road flue 3 , and the bypass flue 3 communicates with the bypass chimney 7 .

[0023] The boiler economizer 4 adopts an H-shaped finned tube economizer. The water inlet of the heat exchange tube 41 of the boiler economizer 4 is connected to the water tank 43 through the water supply pipe 42. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com