Non-contact liquid cooling system for high-power charging and liquid cooling method thereof

A high-power charging, non-contact technology, used in electrical components, electrical equipment structural parts, cooling/ventilation/heating renovation, etc., can solve the problems of shortening charging time, low efficiency, slow heat dissipation, etc., to save product space , the effect of increasing the thermal conductivity area and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

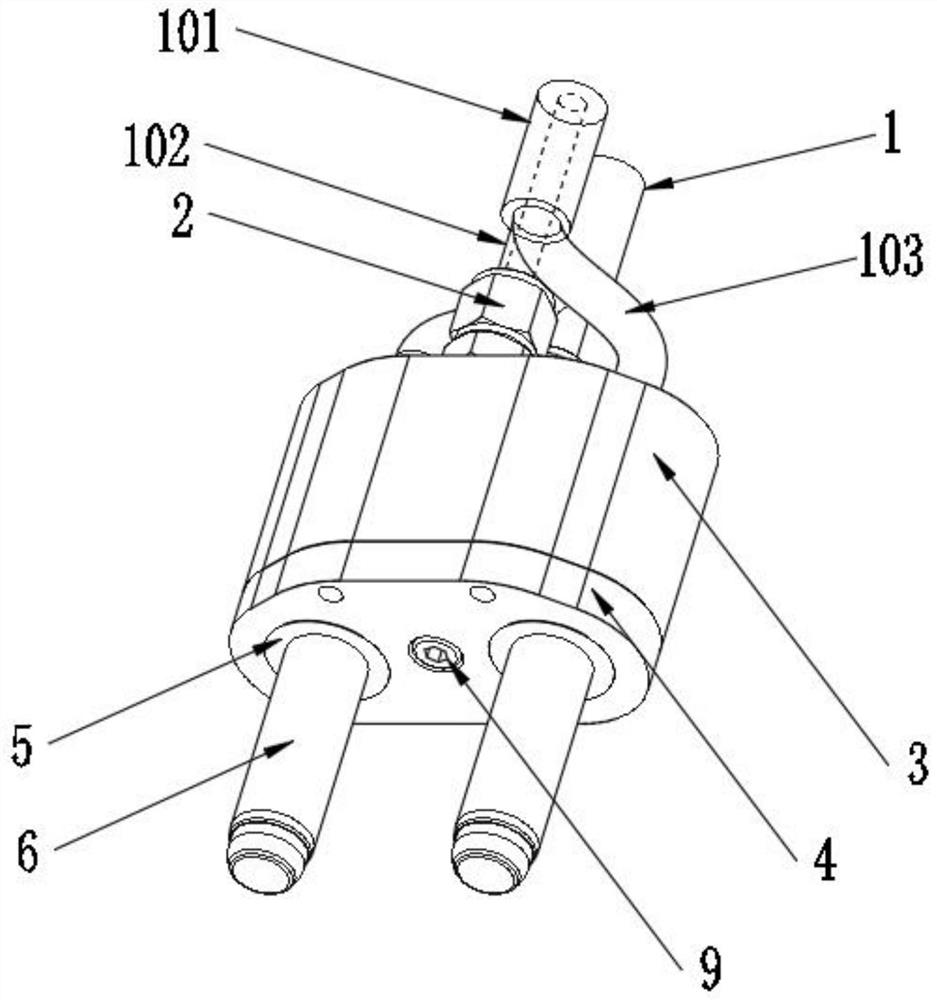

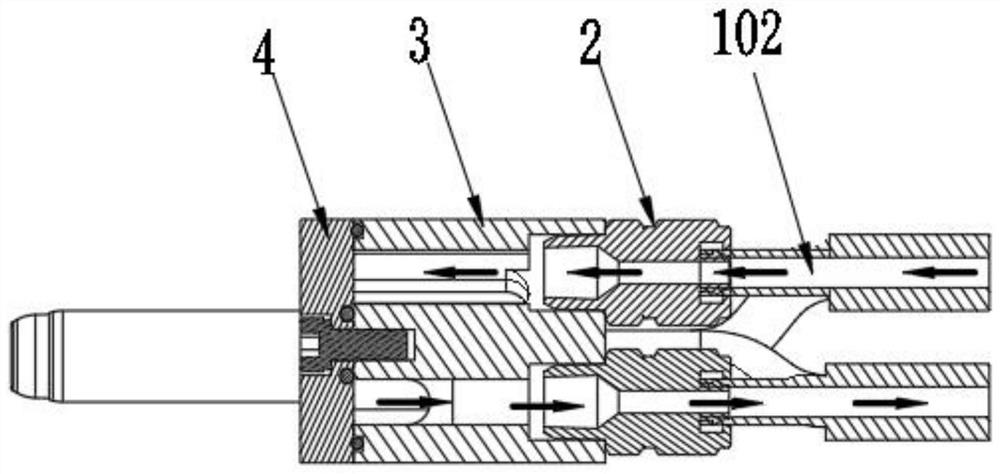

[0033] like Figure 1-4 As shown, the present invention relates to a non-contact liquid cooling system for high-power charging, including a liquid-cooled cable 1, the center of the liquid-cooled cable 1 is provided with a cable built-in pipe 102, and the rear end of the cable built-in pipe 102 is provided with a quick connection Head 2, the outer side of the cable built-in pipe 102 is covered with a cable conductor 103, the outer position of the cable conductor 103 is provided with a cable outer insulating layer 101, the rear end of the cable conductor 103 is crimped with a power terminal 6, and the quick connector 2 is fixed and installed in the liquid On the cold chamber 3, an insulating and heat-conducting member 5 is arranged in the liquid cooling chamber 3;

[0034] A through hole is provided in the middle of the insulating heat conducting member 5 corresponding to the position of the power terminal 6, and the power terminal 6 is located in the through hole of the insulat...

Embodiment 2

[0036] On the basis of Embodiment 1, a non-contact liquid cooling system for high-power charging and a liquid cooling method thereof, comprising the following steps:

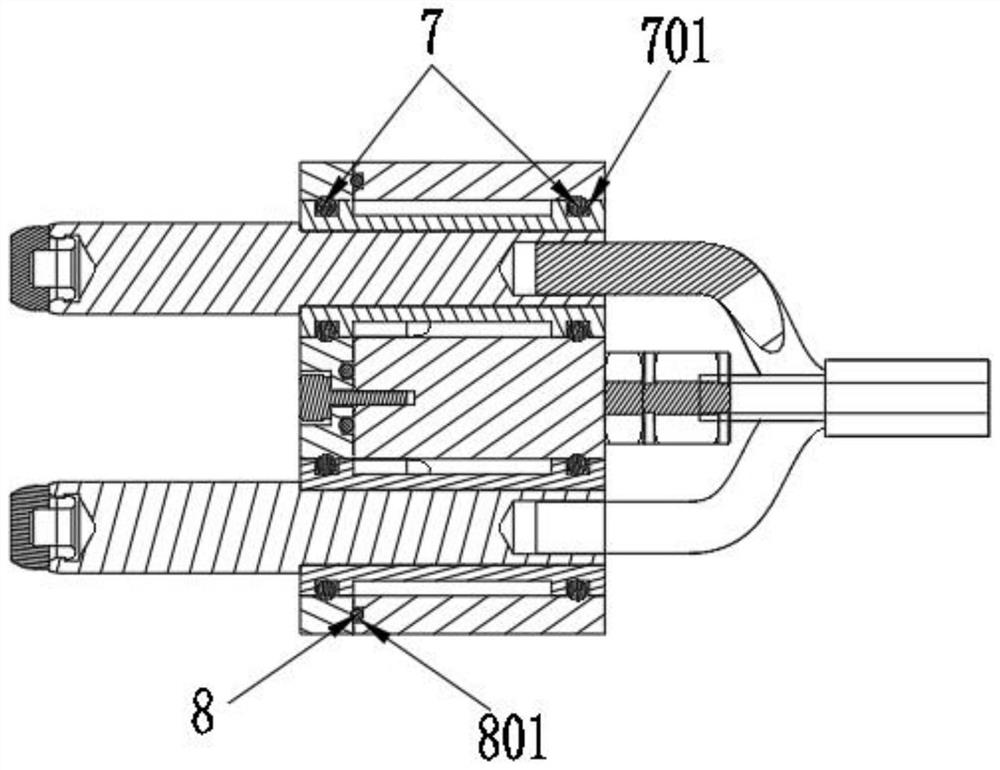

[0037] S1: The liquid-cooled cable 1 is divided into two groups: DC+ / DC-. The cable built-in pipe 102 of the liquid-cooled cable 1 has a liquid inlet pipe and a liquid outlet pipe respectively. The liquid inlet pipe and the liquid outlet pipe are respectively connected to the liquid cooling chamber 3 to form a complete cooling circuit;

[0038] S2: The cable conductor 103 and the power terminal 6 are commonly used in the conventional hexagonal compression method, no special process, simple operation, and high processing efficiency;

[0039] S3: The insulating and heat-conducting part 5 is made of insulating and high-thermal-conducting ceramic parts or other high-thermal-conducting and insulating plastic parts or materials with equivalent performance. touch;

[0040]S4: The insulating and heat-conducting member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com