Cooling system of LED (Light Emitting Diode) lamp

A technology of LED lamps and heat dissipation systems, which is applied in cooling/heating devices of lighting devices, lighting and heating equipment, safety devices of lighting devices, etc., to achieve the effects of increasing heat dissipation area, improving lighting effect and quality, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

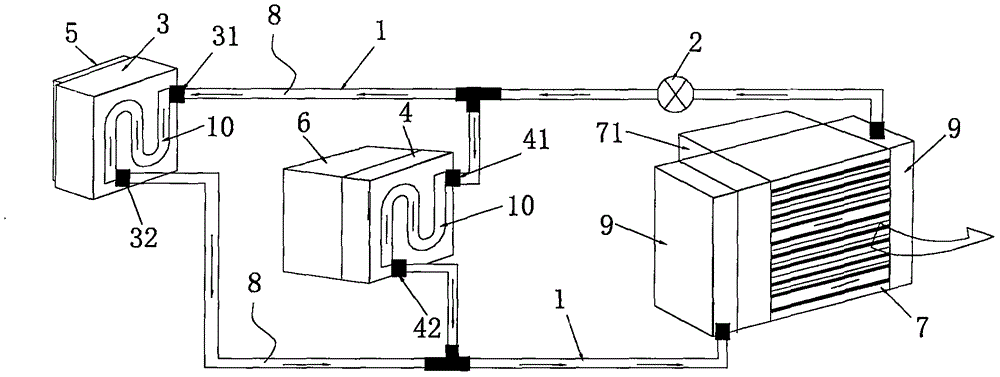

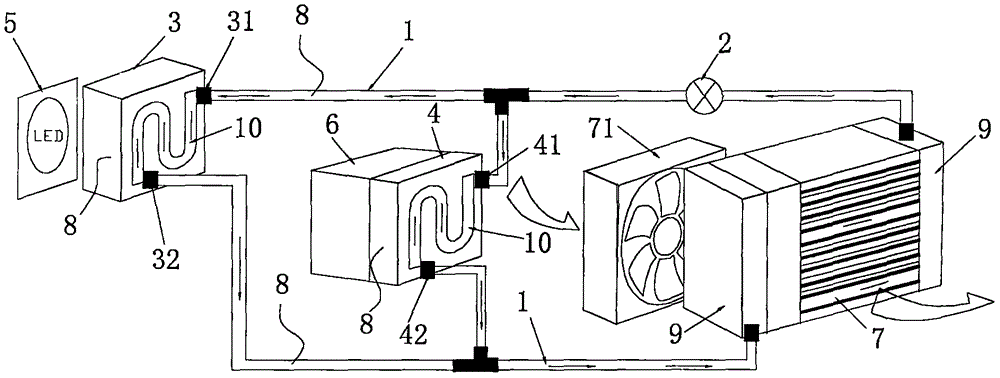

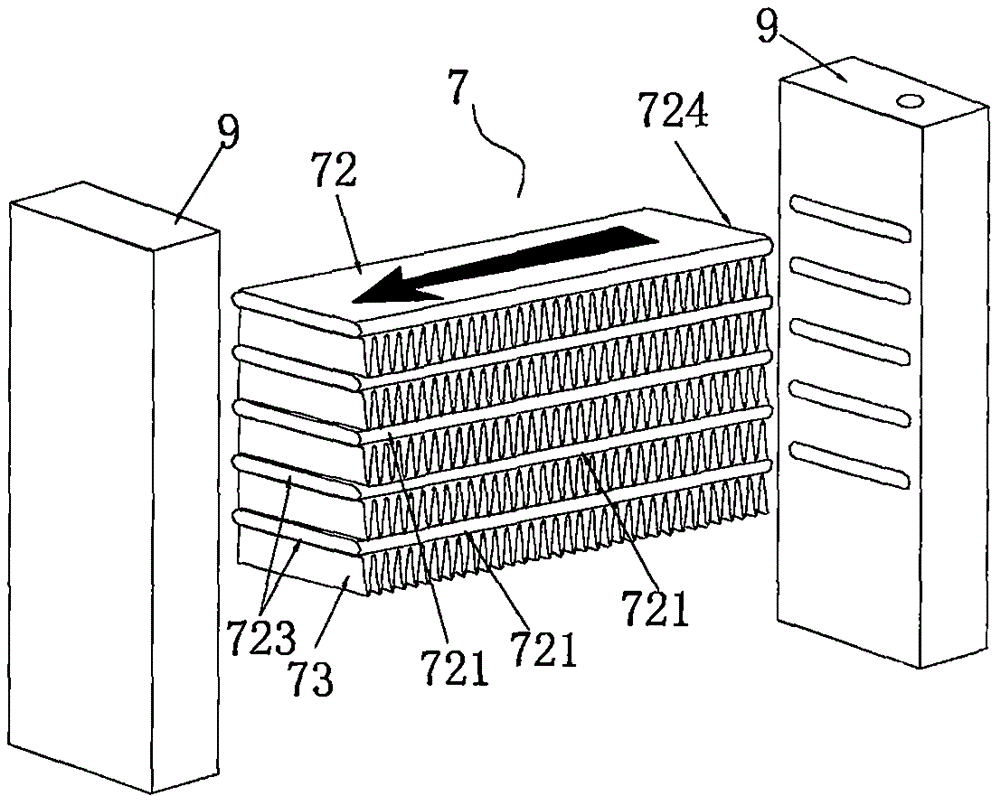

[0029] Embodiment 1: as Figure 1 to Figure 4 The heat dissipation system for an LED lamp shown includes a circulation pipe 1 and a pump 2, and also includes an LED heat dissipation module 3 and a power supply heat dissipation module 4. The LED heat dissipation module 3 is a fluid heat dissipation device for the LED lamp 5. The power cooling module 4 is a fluid cooling device for the LED lamp power module 6; the circulation pipe 1 is connected to the LED cooling module 3 and the power cooling module 4; the specific connection method is as follows figure 1 with figure 2 As shown: the LED cooling module 3, the power cooling module 4 and the circulation pipe 1 are connected in parallel; the pump 2 is installed on the circulation pipe 1, so that the fluid in the circulation pipe 1 passes through the LED heat dissipation module 3 and the power supply. The heat dissipation module 4 forms a circular flow, thereby realizing the heat dissipation and cooling functions of the LED lamp ...

Embodiment 2

[0036] Embodiment 2: The technical feature of this embodiment is that no heat pipe 10 is needed in the LED cooling module 3 (sealed box 1) and the power cooling module 4 of the power module 6 (sealed box 2). All the other are the same as the above embodiment.

[0037] When the present invention is applied, the LED cooling module 3 (sealed box one), the power supply cooling module 4 (sealed box two) and the water collection tank 9 are filled with fluid 8, and the fluid 8 includes silicone oil, water, etc. Coolant with thermal conductivity. When the LED light is turned on, the water pump 2 on the circulation pipe 1 is started at the same time, so that the fluid 8 flows between the LED heat dissipation module 3 (sealed box 1) of the LED light 5 and the power heat dissipation module 4 of the power module 6 (sealed box 2) Circulating flow between the water collection tank 9 of the radiator 7. During the fluid circulation process, the heat generated by the LED lamp 5 is transferre...

Embodiment 3

[0038] Embodiment 3: as Figure 5 The heat dissipation system for LED lamps shown in this embodiment has the technical characteristics that: the LED heat dissipation module 3 , the power supply heat dissipation module 4 and the circulation pipe 1 are connected in series. All the other are the same as the above embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com