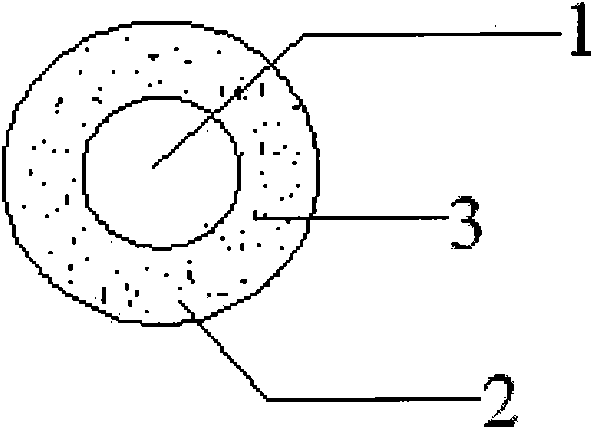

Magnetic phase transition microcapsule and preparation method thereof

A magnetic phase change and microcapsule technology, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of non-magnetism, inability to solve local overheating, fluid flow control, etc., and achieve low cost and preparation The method is simple and easy, and the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

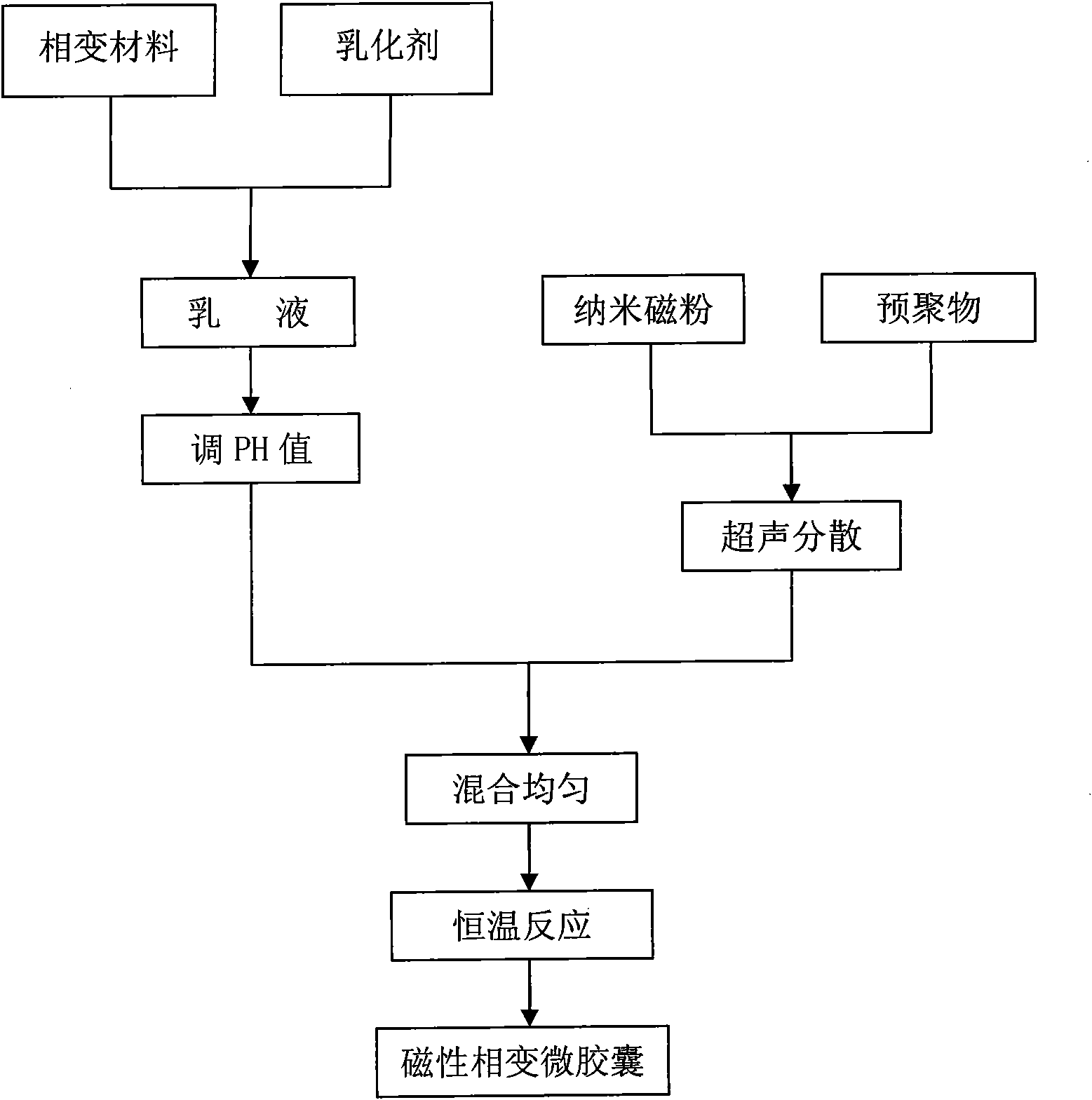

[0020] 1. First weigh 13.6940 grams of solid paraffin, then weigh 7.8251 grams of urea and 15.8618 grams of 37% formaldehyde solution according to the formula.

[0021] 2. Add urea to the formaldehyde solution in batches within 5 minutes, adjust the pH value to 8-9 with triethanolamine, and react at a constant temperature of 70°C for 1 hour under stirring with an electric mixer to obtain a urea-formaldehyde prepolymer solution. Add 0.2076 g of nano-iron powder to the polymer solution, and disperse it ultrasonically for 1.5 hours;

[0022] 3. Dissolve 0.2068 g of sodium dodecylsulfonate in 200 mL of deionized water, adjust the pH to 2 to 3 with citric acid, add solid paraffin to mix and melt, and stir vigorously with an electric mixer for 1 hour to make a paraffin wax emulsion;

[0023] 4. Mix the paraffin emulsion with the ultrasonically dispersed prepolymer, and stir evenly with an electric mixer;

[0024] 5. Stir the reactants with a motor, react at a constant temperature o...

Embodiment 2

[0026] 1. First weigh 12.8564 grams of n-octadecane, then weigh 3.6216 grams of urea, 3.8025 grams of melamine and 14.6820 grams of 37% formaldehyde solution according to the formula.

[0027] 2. Add urea into the formaldehyde solution in batches within 5 minutes, add melamine after the urea is completely dissolved, adjust the pH value to 8-9 with triethanolamine, and react at a constant temperature of 75°C for 1.25 hours under stirring with an electric mixer to obtain urea- Melamine-formaldehyde prepolymer solution, add 0.6435 grams of nano-iron powder to the prepolymer solution, and ultrasonically disperse for 1 hour;

[0028] 3. Dissolve 0.1949 g of Tween 60 in 200 mL of deionized water, adjust the pH to 2 to 3 with citric acid, add n-octadecane to melt, stir vigorously with an electric mixer for 1 hour, and make n-octadecane emulsion;

[0029] 4. Mix the n-octadecane emulsion with the ultrasonically dispersed prepolymer, and stir evenly with an electric mixer;

[0030] 5....

Embodiment 3

[0032] 1. First weigh 14.5396 grams of n-tetradecane, and then weigh 8.4797 grams of melamine and 16.3708 grams of 37% formaldehyde solution according to the formula.

[0033] 2. Add melamine to the formaldehyde solution, adjust the pH value to 8-9 with triethanolamine, and react at a constant temperature of 65°C for 45 minutes under stirring with an electric mixer to obtain a melamine-formaldehyde prepolymer solution. Add 0.4362 gram nanometer ferric oxide, and ultrasonically dispersed for 0.5 hours;

[0034] 3. Dissolve 0.2181 g of sodium dodecylbenzenesulfonate in deionized water, adjust the pH value to 2 to 3 with citric acid, add n-tetradecane to melt, stir vigorously with an electric mixer for 1 hour, and make positive ten Tetrane emulsion;

[0035] 4. Mix the n-tetradecane emulsion with the ultrasonically dispersed prepolymer, and stir evenly with an electric mixer;

[0036] 5. Stir the reactants with a motor, react at a constant temperature of 85°C for 3 to 6 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com