Heat dissipation device

a heat dissipation device and heat dissipation fin technology, which is applied in the direction of electrical apparatus casings/cabinets/drawers, semiconductor/solid-state device details, stoves or ranges, etc., can solve the problems of insufficient heat dissipation, heat dissipation efficiency could be affected, and the heat dissipation device composed of heat dissipating fins and fans could not meet the heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

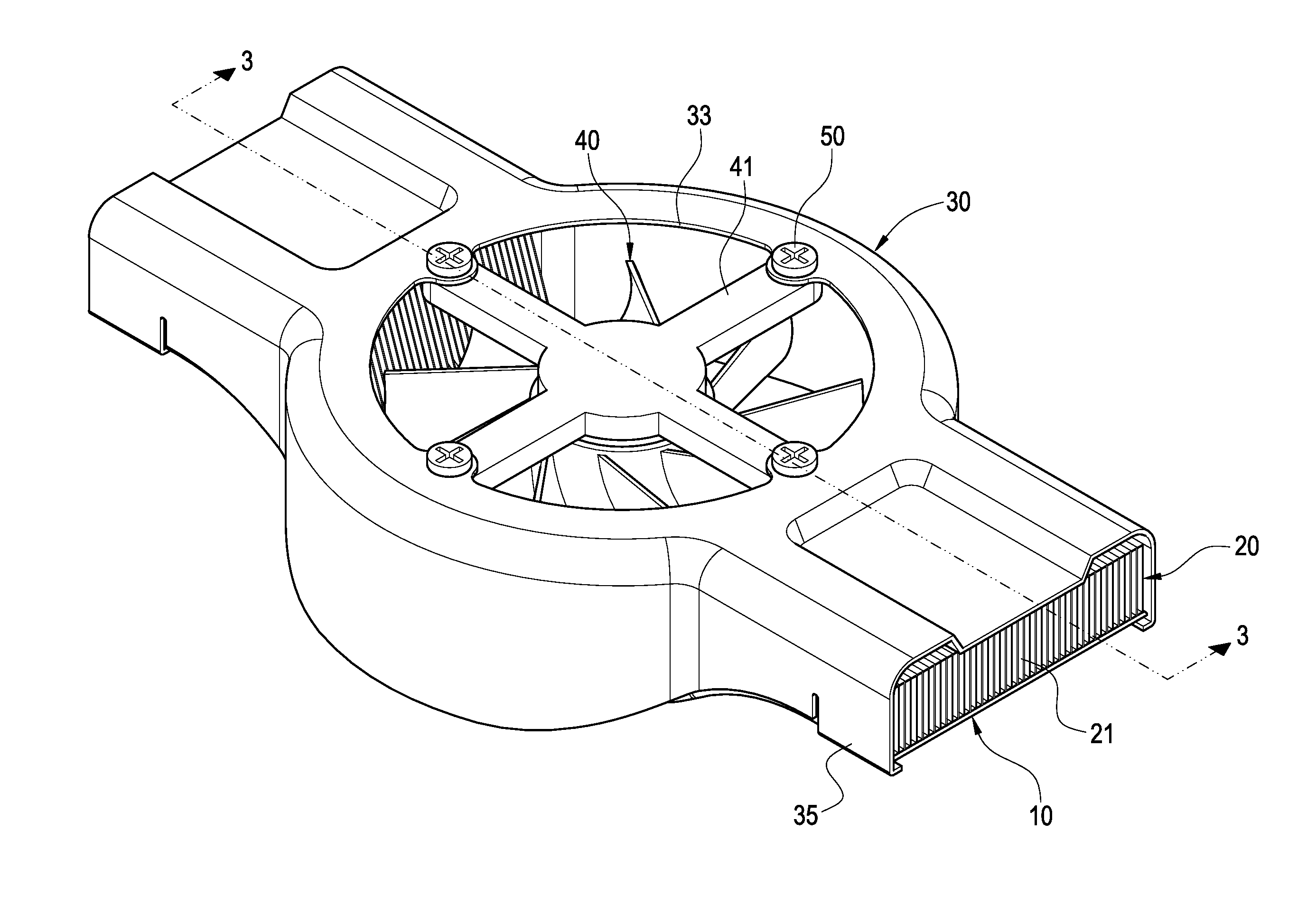

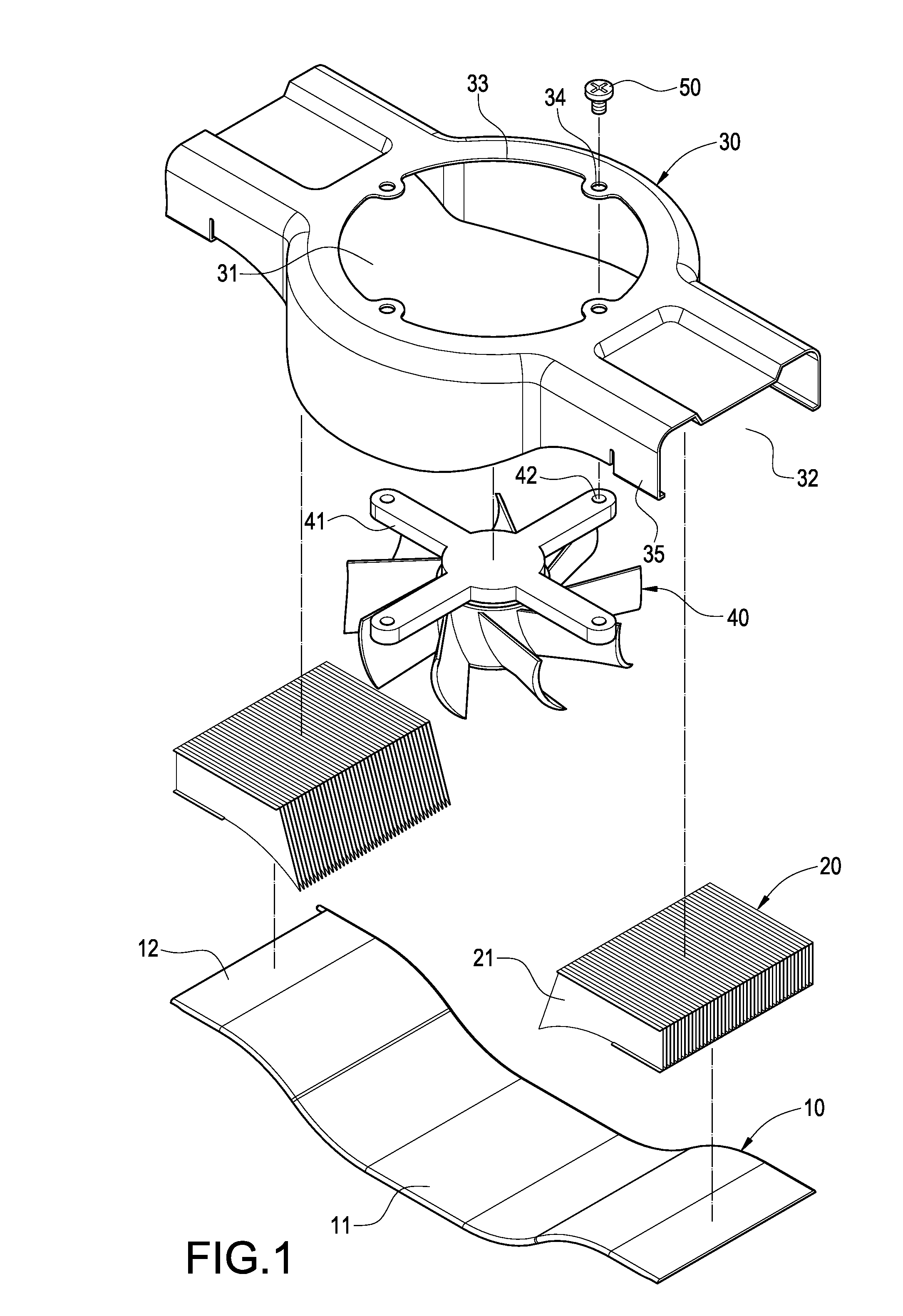

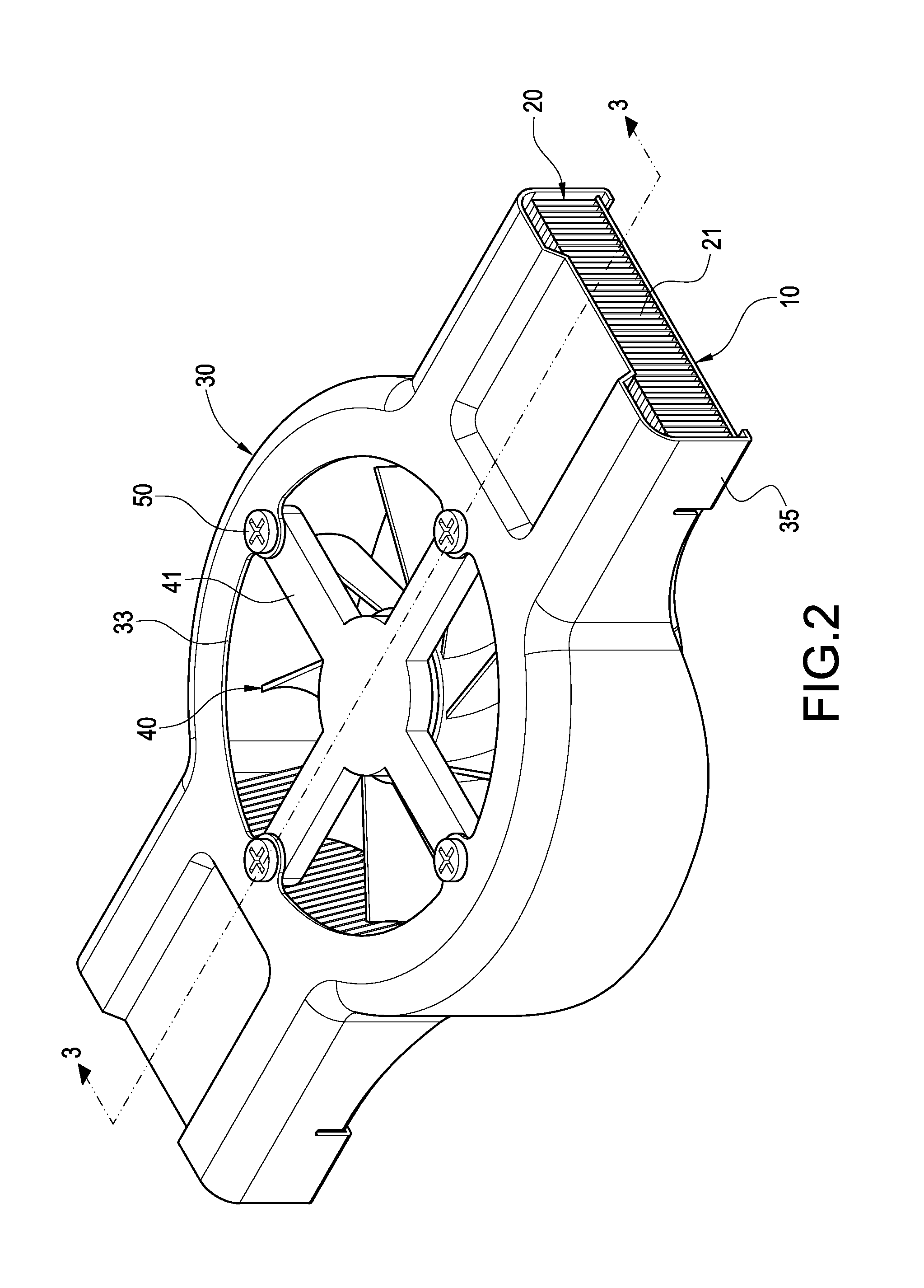

[0015]Referring to FIG. 1 and FIG. 4, a heat dissipation device of an exemplary of the present invention includes a vapor chamber 10, a heat dissipating fins assembly 20, a cover 30 and a fan 40.

[0016]The vapor chamber 10 is made in a strip structure and is configured to a bent shape. The vapor chamber 10 includes a heat absorbing portion 11 and two heat emitting portion 12 deformedly extending from opposite sides of the absorbing portion 11. The absorbing portion 11 protrudes from the surface of the emitting portions 12. The absorbing portion 11 is adhered to a surface of a heat generating element 62 (as shown in FIG. 5). A large heat dissipating area is configured at the heat dissipating portion 12 and heat absorbing portion 11. The heat generating element 62 is a CPU, a semiconductor packing part, a wafer or other electronic elements with high heat generation.

[0017]The heat dissipating fins assembly 20 is adhered to a partial surface of the vapor chamber 10, preferrably, the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com