Radiator suitable for aluminium alloy cavity nickel coated anti-corrosion

A technology of aluminum alloy and heat sink, which is applied in the field of inner cavity plating Ni-P anti-corrosion heat sink, which can solve the problems of poor coating uniformity, poor storage resistance, leak coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

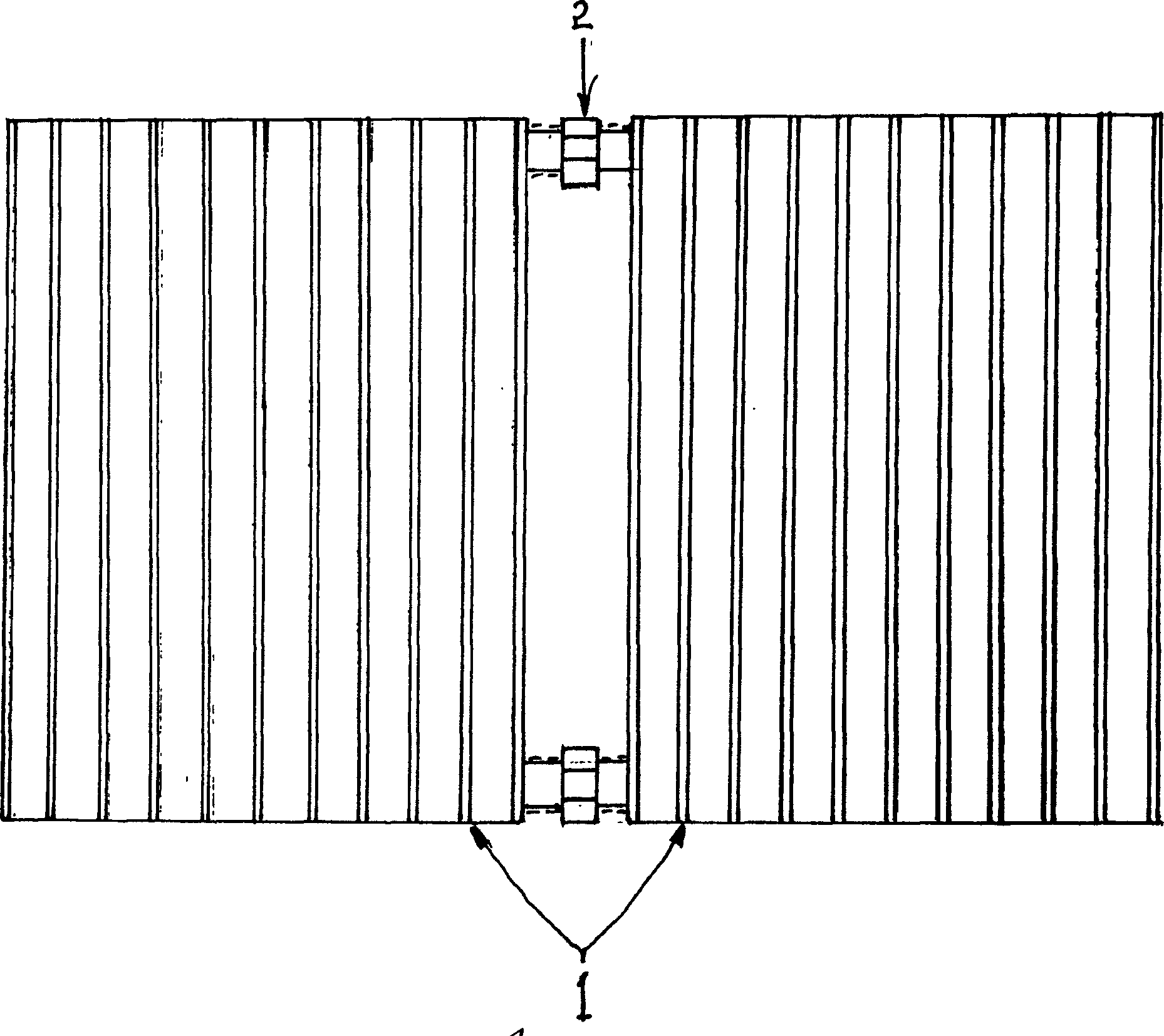

[0016] figure 1 It is a front view of a heat sink suitable for nickel-plated anti-corrosion aluminum alloy inner cavity, and it is also an embodiment of the design product, which is assembled by two heat sinks.

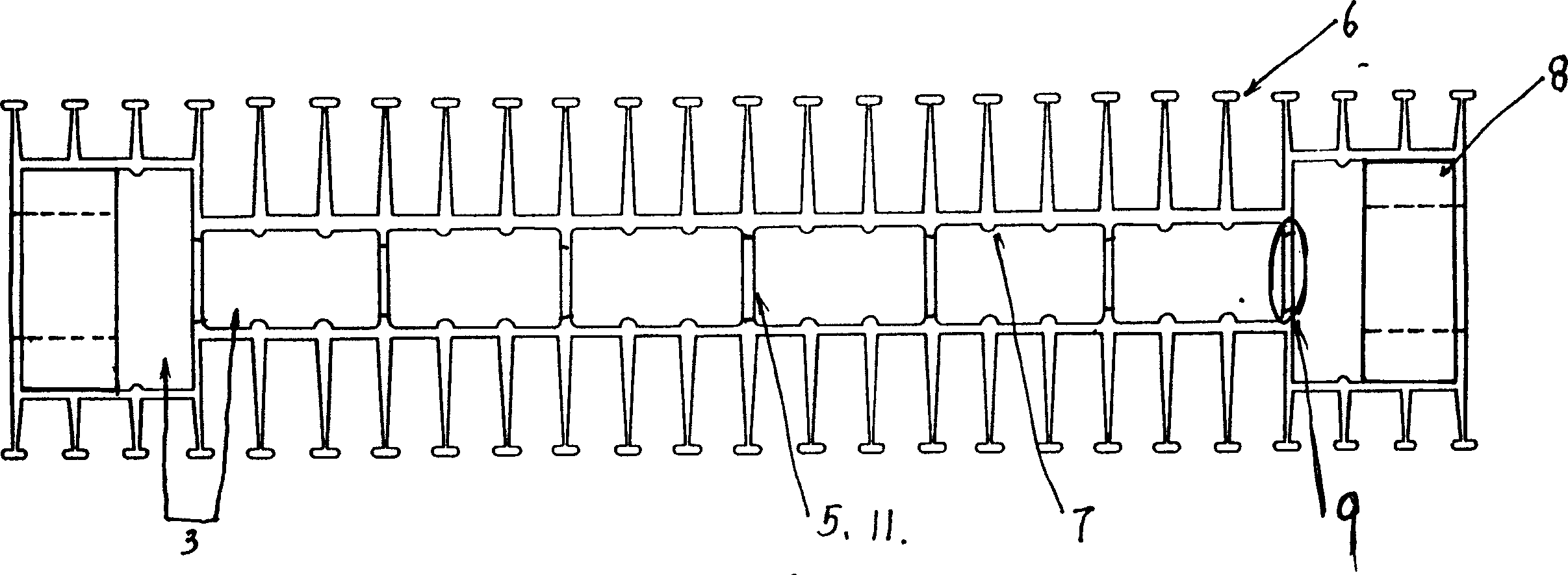

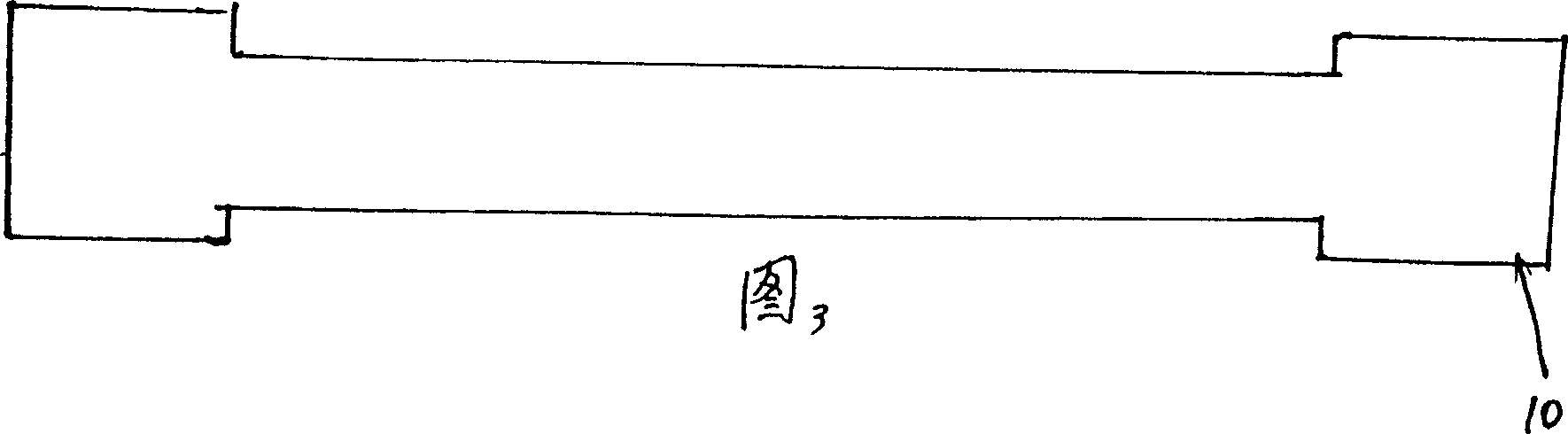

[0017] Figure 5 , 6 , 7, 8, 9, and 10 are aluminum alloy heat sinks connected by 2 connecting combination devices 2, attached figure 2 , 3, 4 are the cross-sectional diagrams of the loose pieces, and they are also attached figure 1 In the middle two heat sinks 1, there are 8 water channels 3 in the figure, 7 reinforcing ribs 5, and 25 heat dissipation fins 6 on both sides. Since there are as many as 25 heat dissipation fins, the heat dissipation area can be increased. The main reason for the high thermal efficiency of the new product is that the heat dissipation fins of this embodiment are T-shaped, which increases the sense of decoration. The water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com