Large-flow automatic vent valve for supercavitation aircraft

An aircraft and large flow technology, applied in the direction of sliding valves, valve devices, ventilation devices, etc., can solve the problems of small air flow and difficulty in reaching the air flow of supercavitation aircraft, and achieve improved service life, simple operation, and safety good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

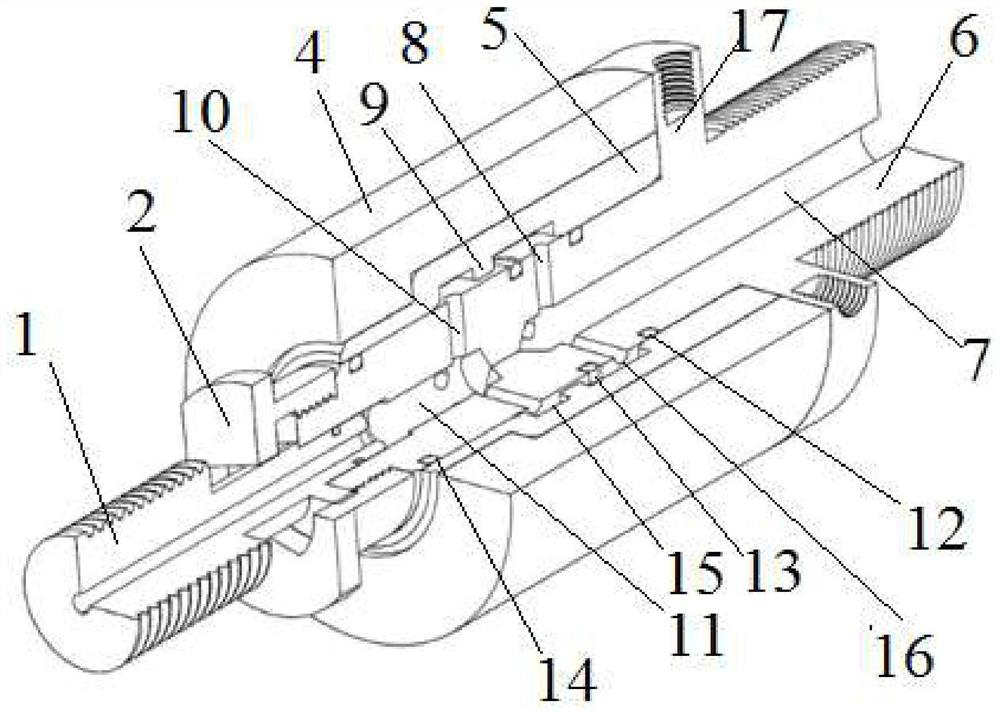

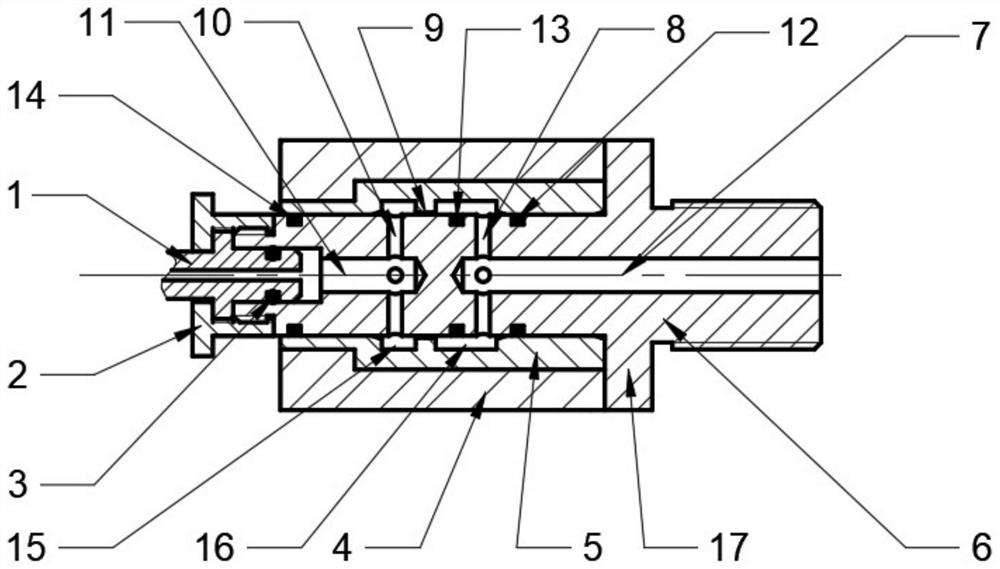

[0032] A kind of supercavitation aircraft of the present invention uses large-flow automatic ventilation valve, as figure 1 As shown, including the valve seat 6, one end of the valve seat 6 is provided with a first axial vent hole 7 along the axial direction, and the other end is provided with a second axial vent hole 11 along the axial direction. The first radial vent hole 8 communicated with the axial vent hole 7 and the second radial vent hole 10 communicated with the second axial vent hole 11; The ring groove 16, the second ring groove 15, the first ring groove 16 communicates with the second ring groove 15, the distance between the first ring groove 16 and the second ring groove 15 is smaller than the first radial vent hole 8 and the second radial vent hole 10 spacing.

[0033] The outer wall of the valve sleeve 5 cooperates with the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com