Rotor punched sheet air path structure

A rotor punching and air channel technology, applied in the field of rotor punching air channel structure, can solve the problems of reduced motor efficiency, large mechanical loss, multi-radial air channels, etc., achieve uniform and reasonable temperature distribution, improve insulation service life, The effect of increasing the ventilation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

[0025] A wind path structure for rotor sheeting of the present invention is applied to conventional motors. The motor is composed of a stator, a rotor, a machine base, a bearing and its auxiliary structural parts, wherein the stator is radially ventilated. The right end of the motor is defined as the air inlet, and the left end of the motor is the air outlet. A fan is installed at the air outlet and connected to an external cooling system to form an air cooling cycle.

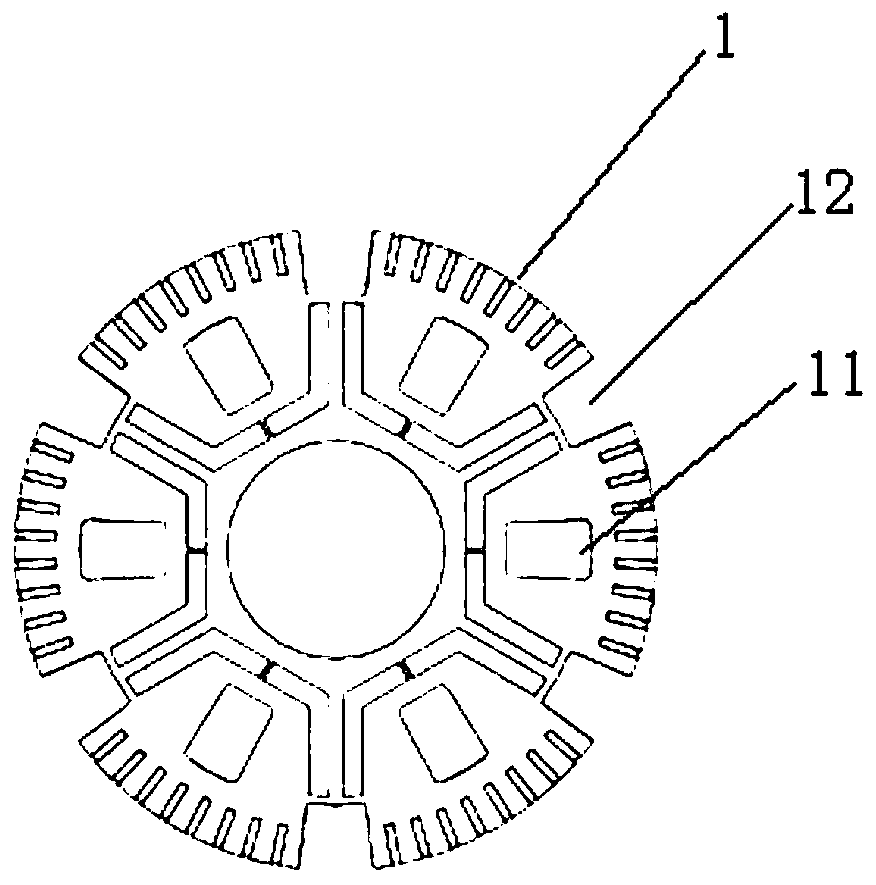

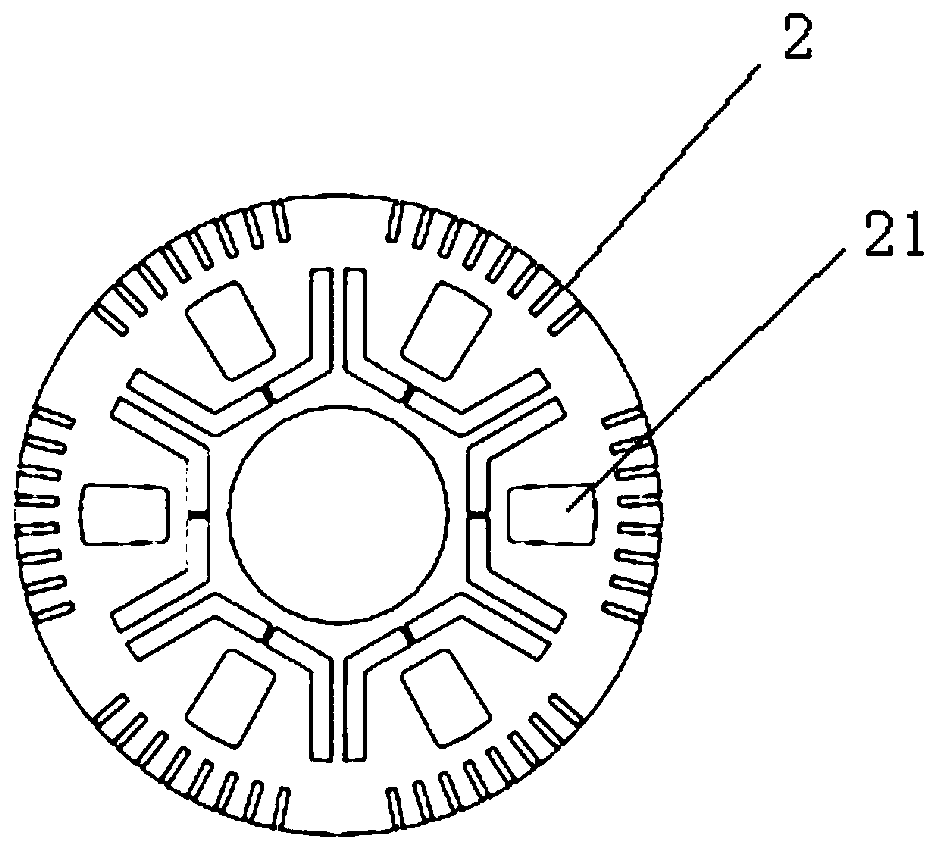

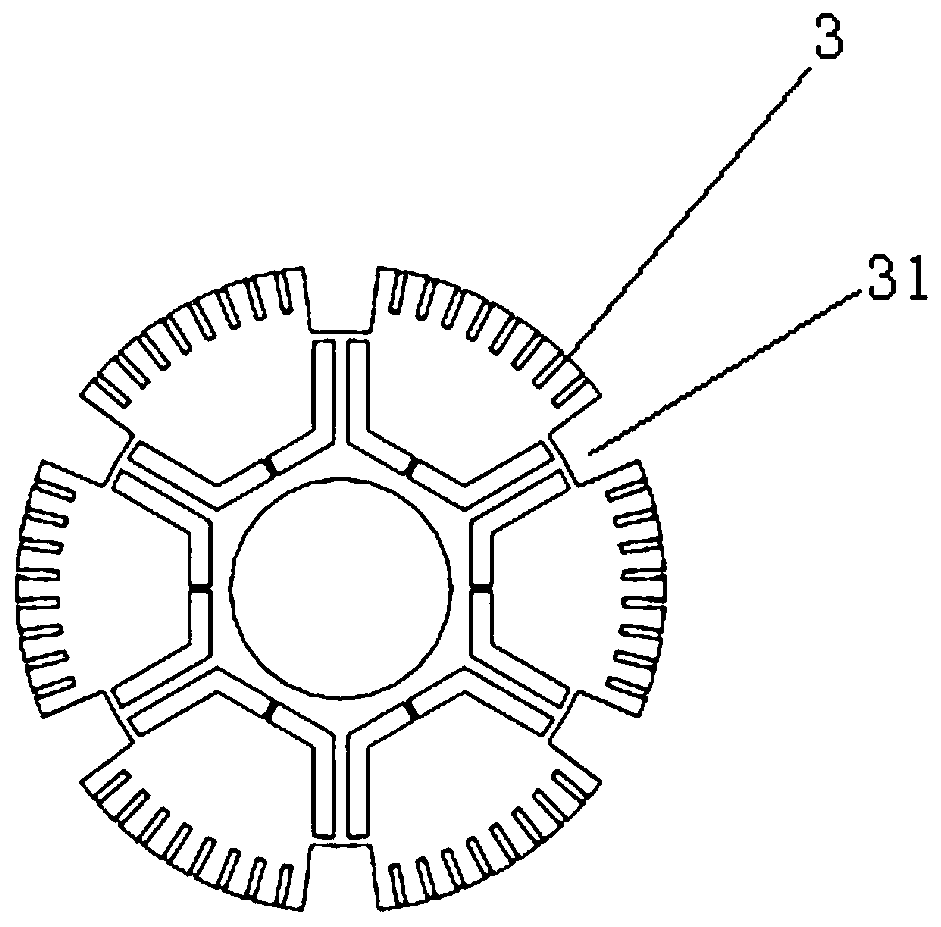

[0026] The motor rotor core is formed by stacking rotor punches, including a first rotor punch 1 , a second rotor punch 2 laminated with each other, a third rotor punch 3 and a fourth rotor punch 4 laminated with each other.

[0027] The right part of the rotor core is formed by laminating the first rotor punch 1 and the second rotor punch 2 . see figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com