Patents

Literature

78results about How to "Improve insulation life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

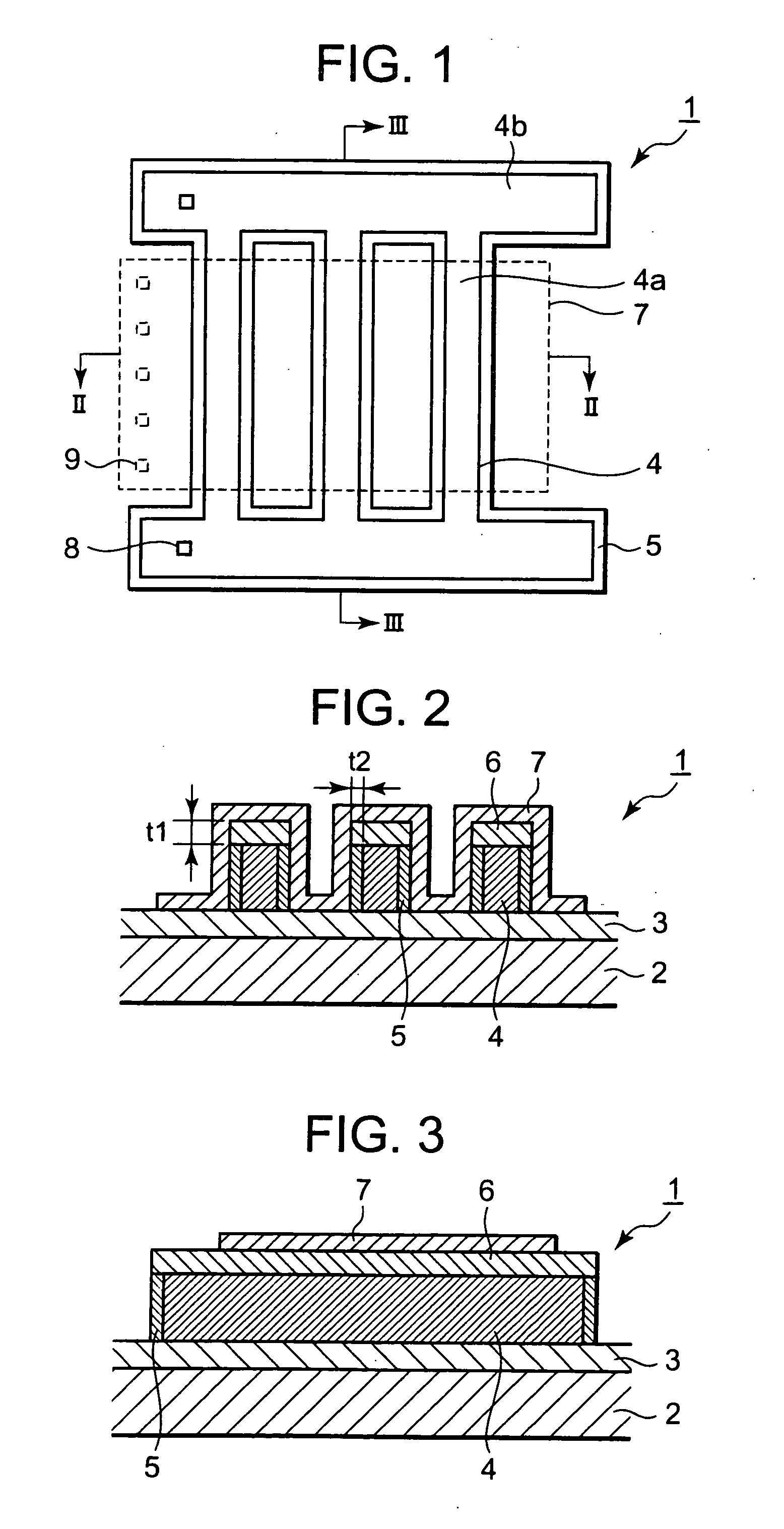

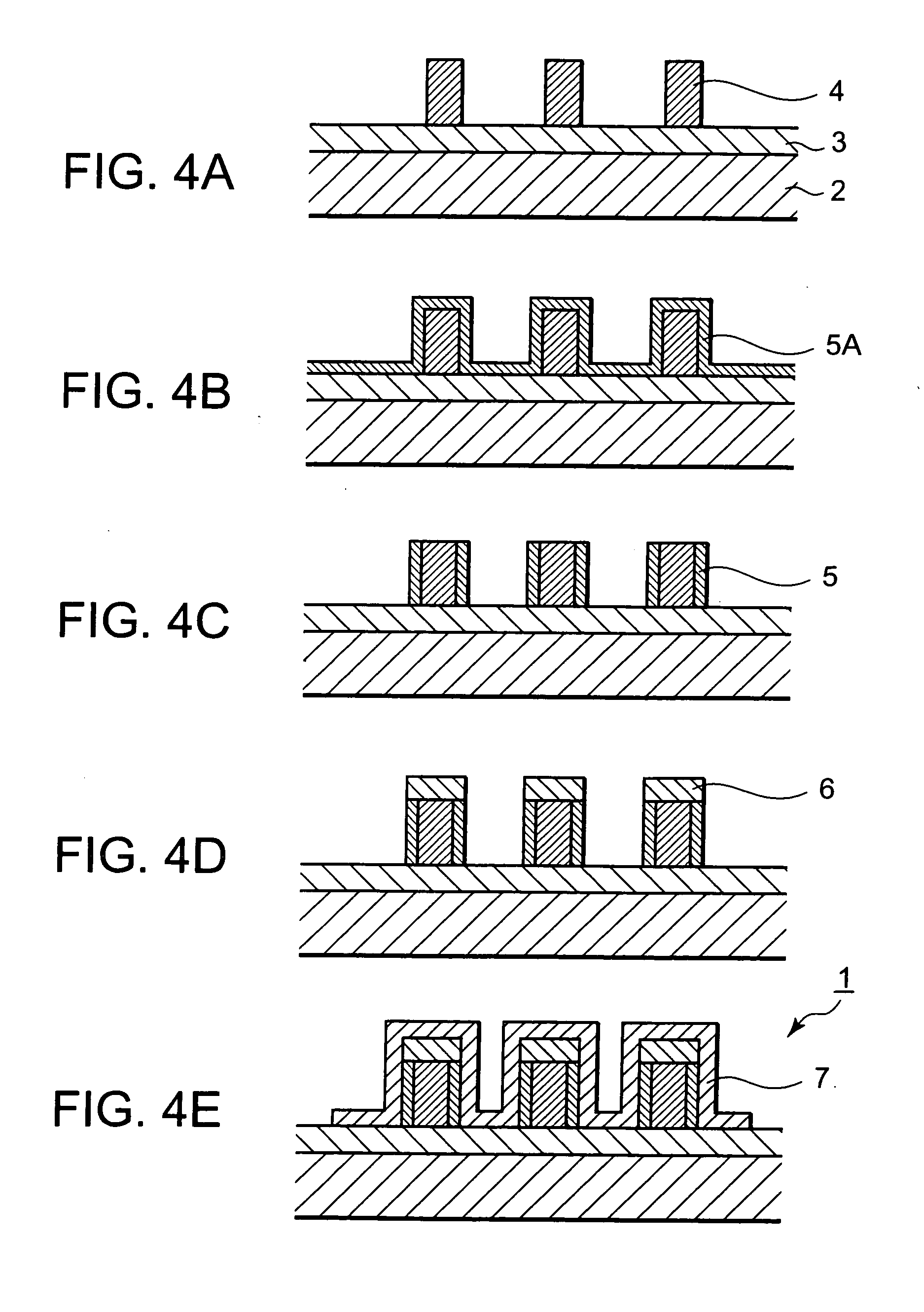

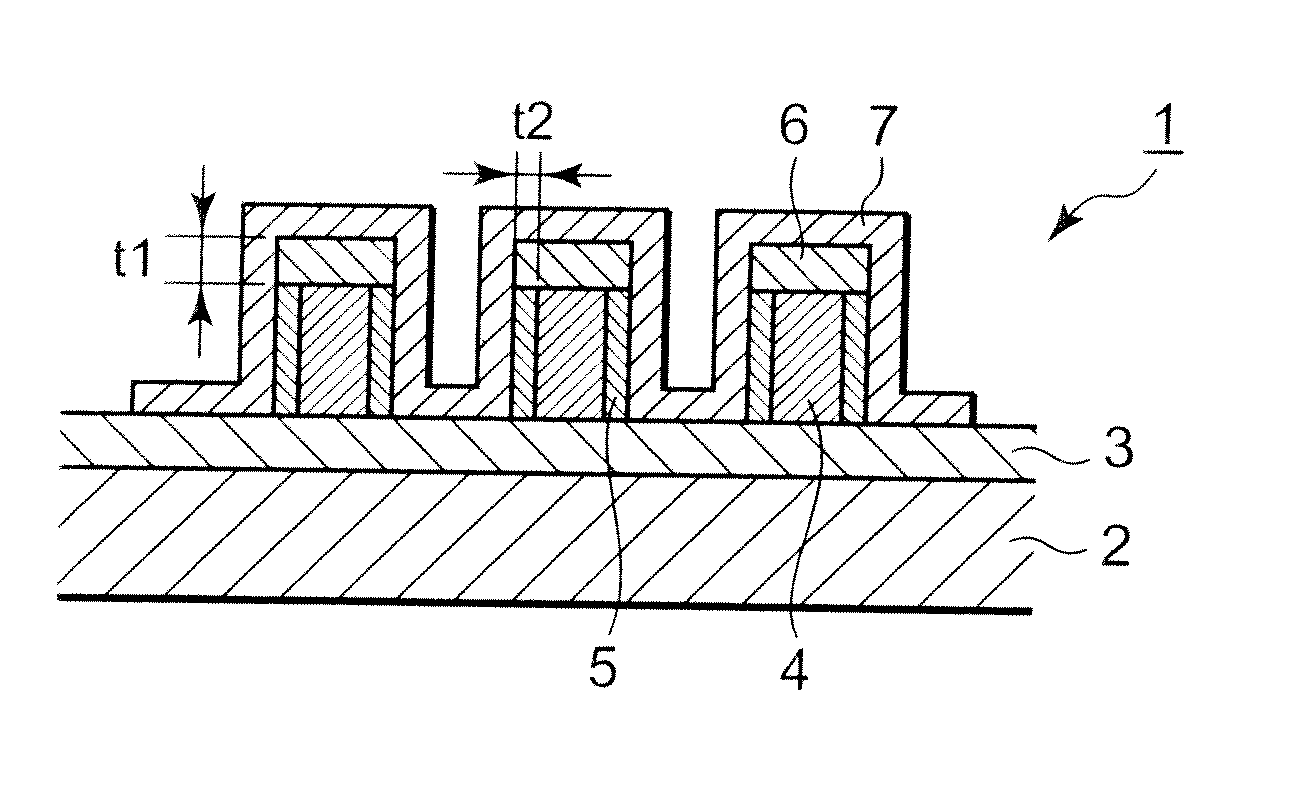

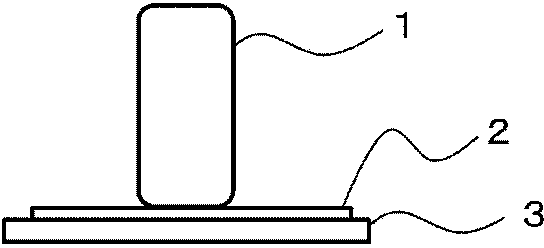

Semiconductor integrated circuit device and method of manufacturing the same

InactiveUS20100213520A1Improve insulation lifeProlong lifeTransistorSolid-state devicesElectrical conductorEngineering

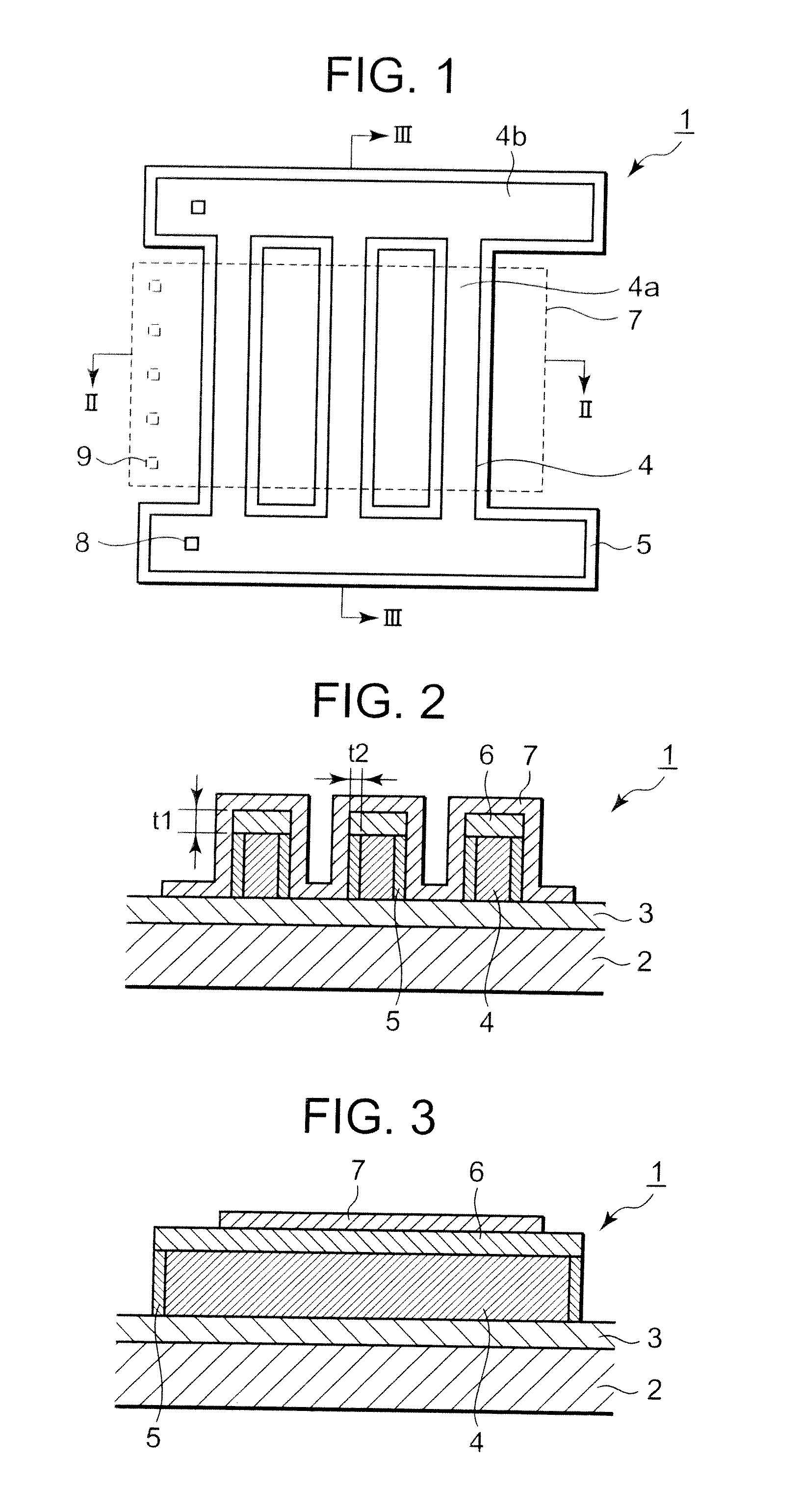

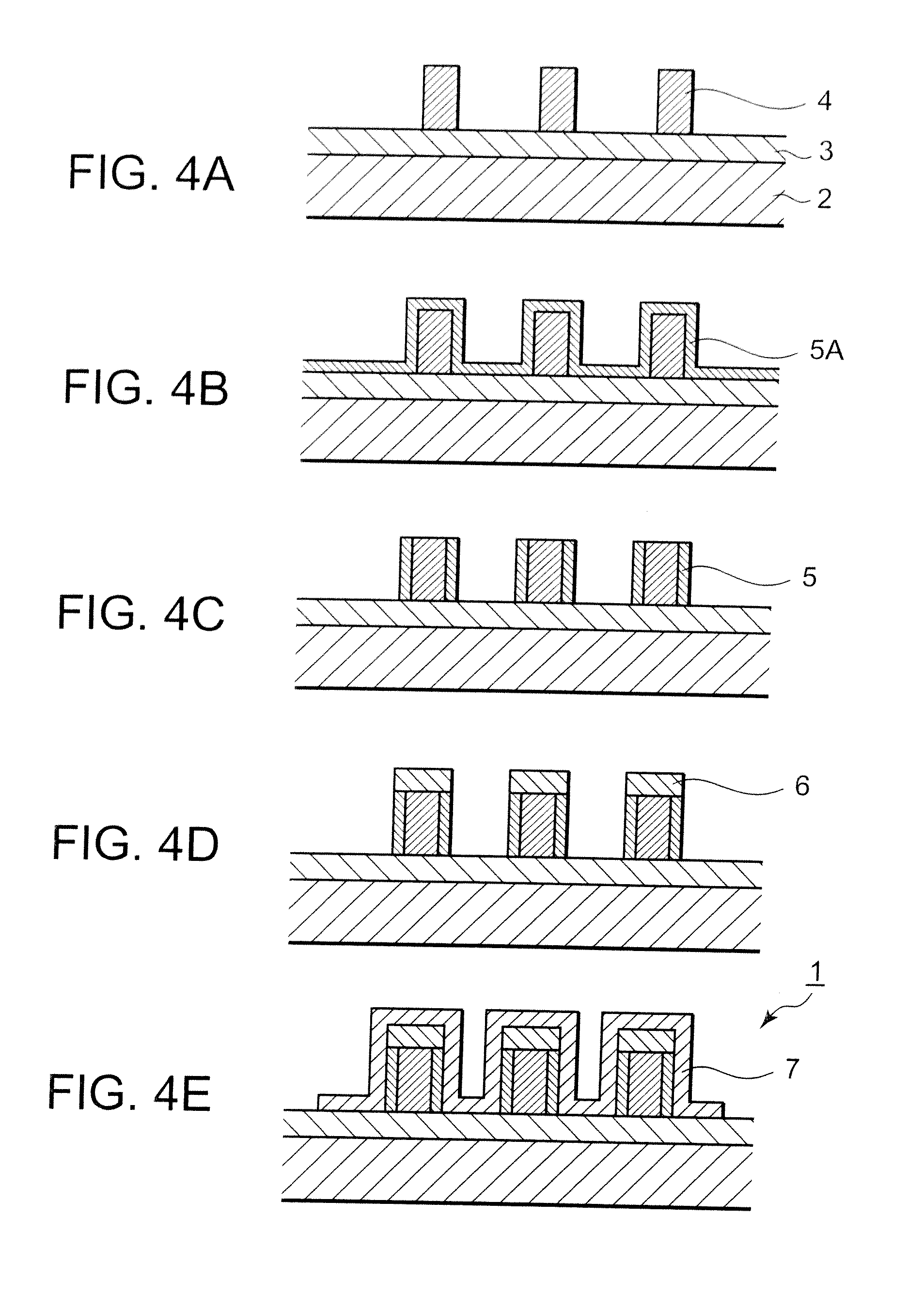

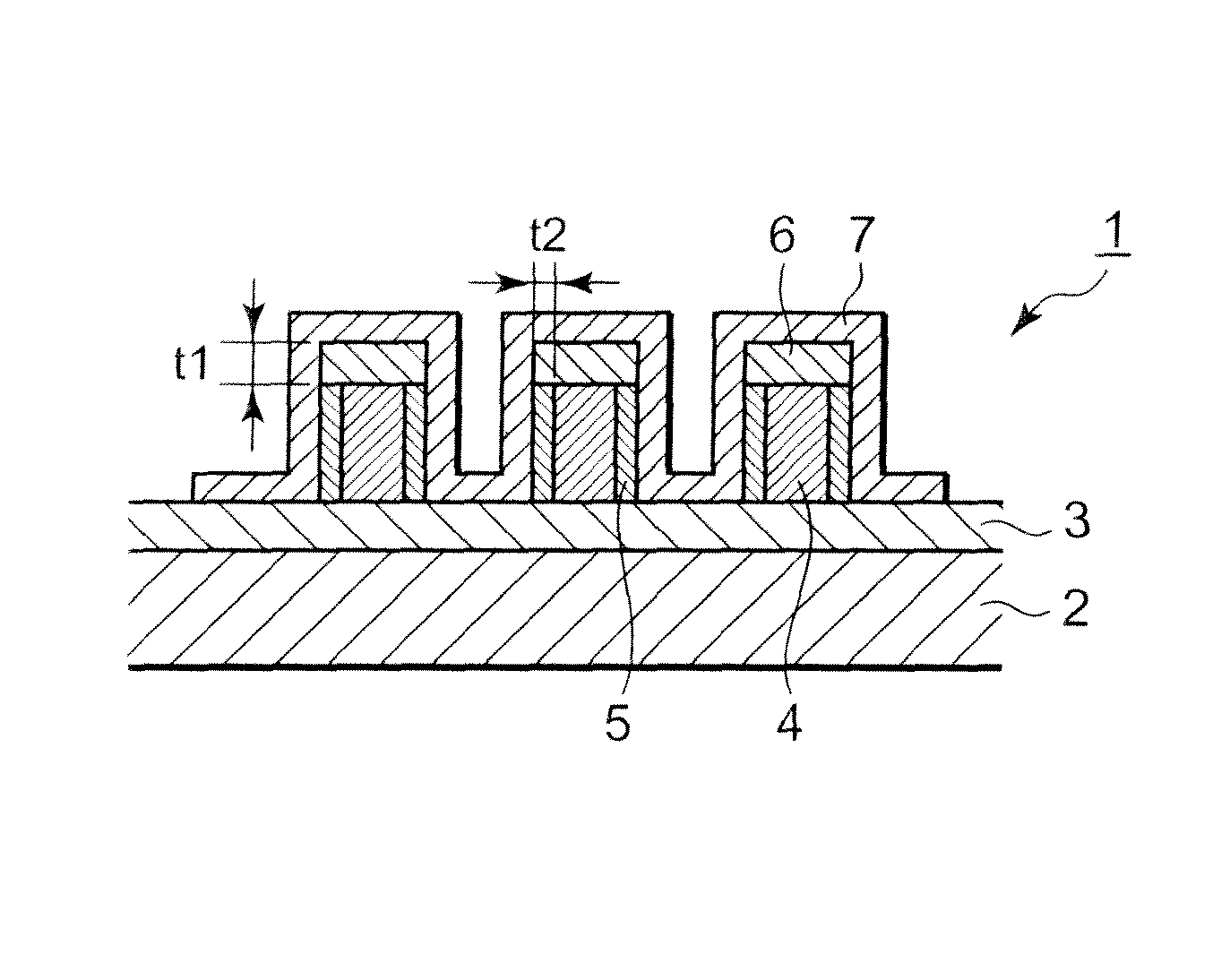

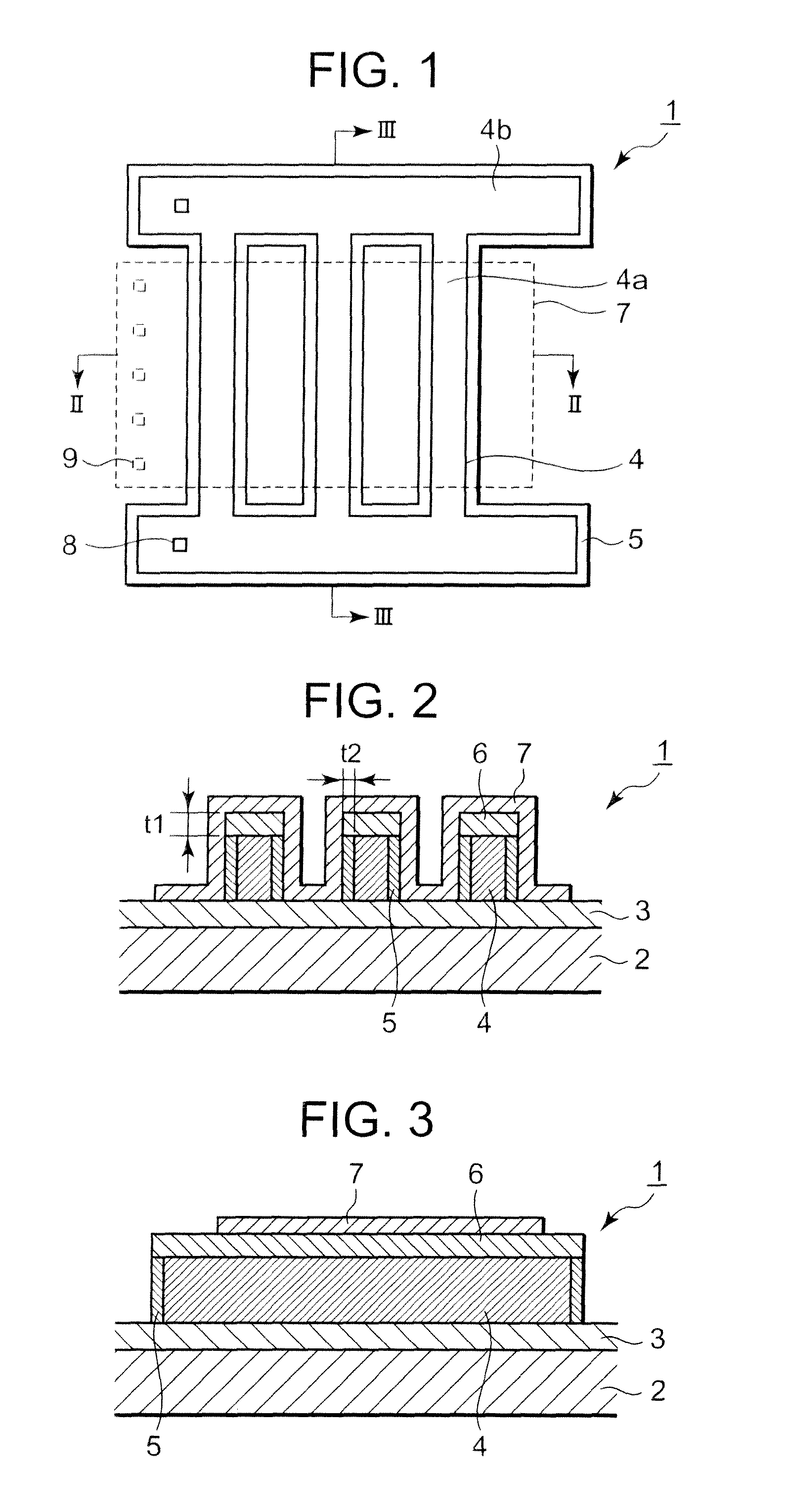

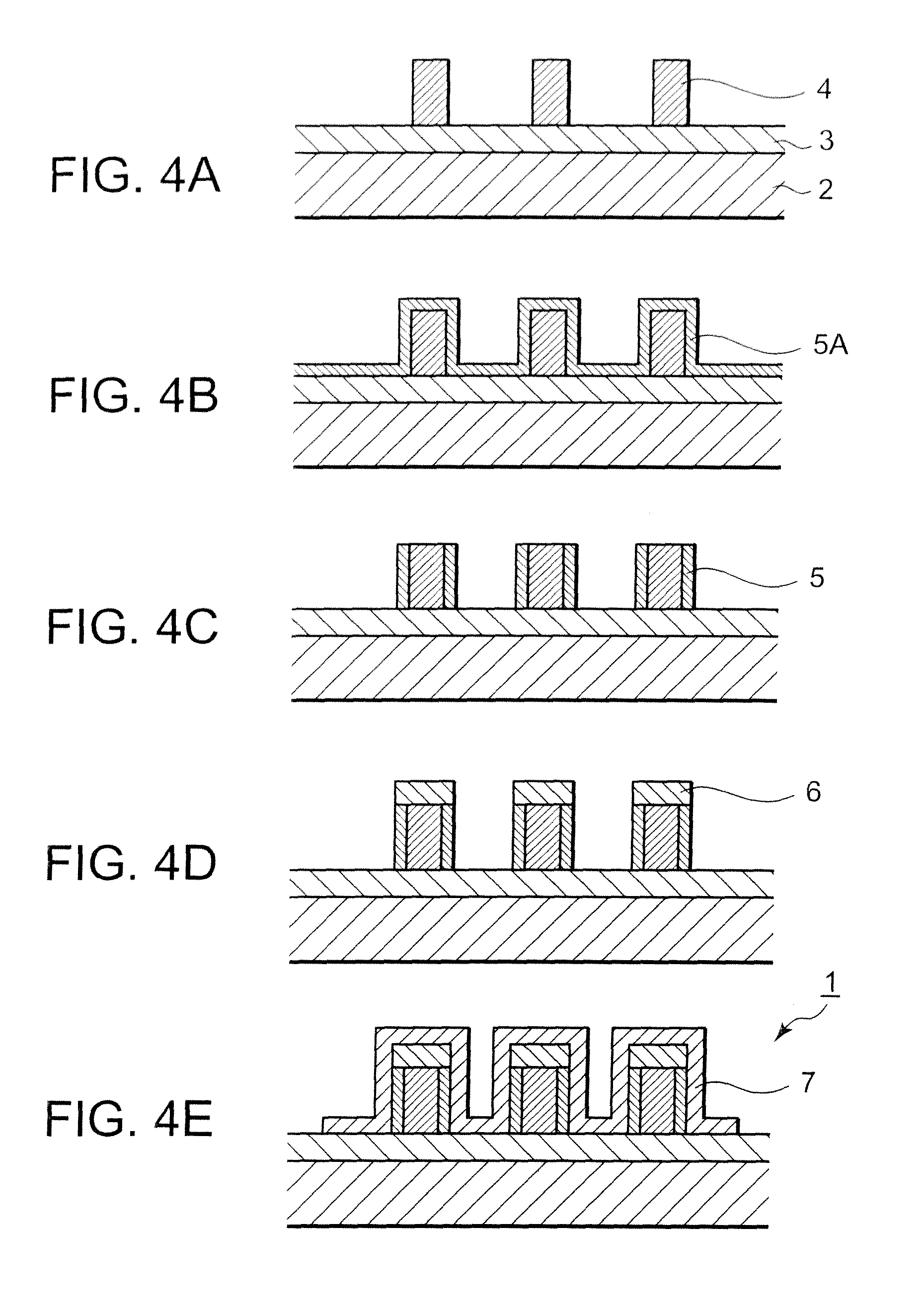

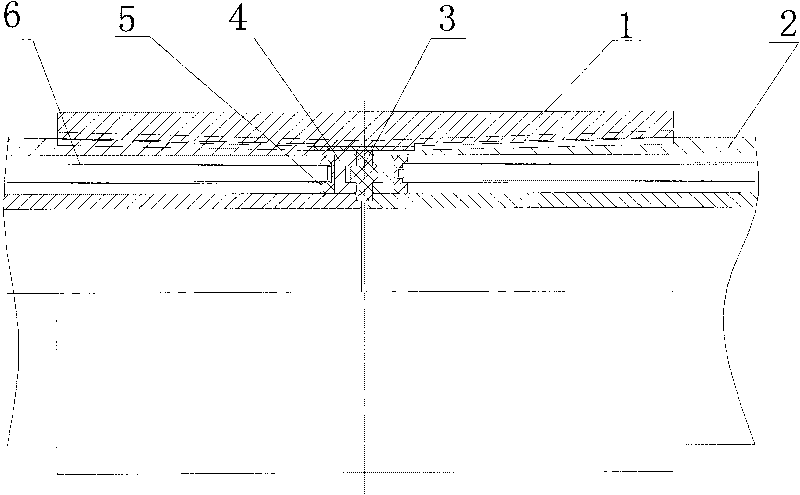

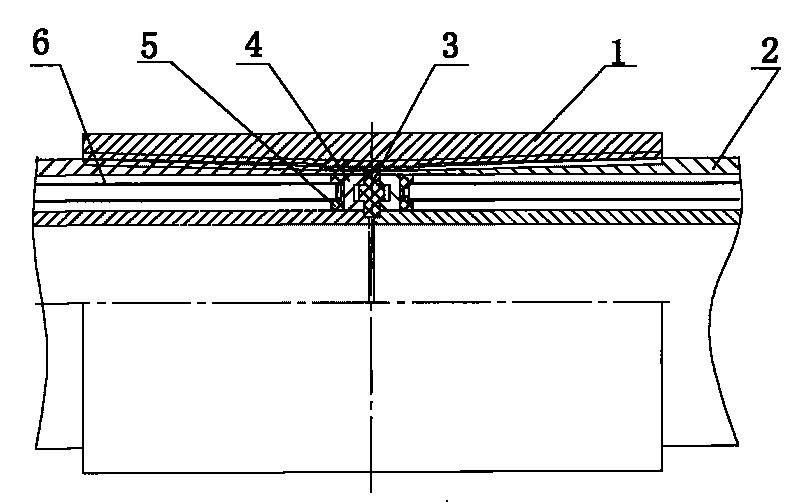

Provided is a semiconductor integrated circuit device including a capacitor element with an improved TDDB life. A semiconductor integrated circuit device (1) includes: a first electrode (4) including a first semiconductor layer which protrudes with respect to a plane of a substrate; a side surface insulating film (5) formed on at least a part of a side surface of the first electrode (4); an upper surface insulating film (6) formed on the first electrode (4) and the side surface insulating film (5); and a second electrode (7) which covers the side surface insulating film (5) and the upper surface insulating film (6). The first electrode (4), the side surface insulating film (5), and the second electrode (7) constitute a capacitor element. A thickness of the upper surface insulating film (6) between the first electrode (4) and the second electrode (7) is larger than a thickness of the side surface insulating film (5) between the first electrode (4) and the second electrode (7).

Owner:RENESAS ELECTRONICS CORP

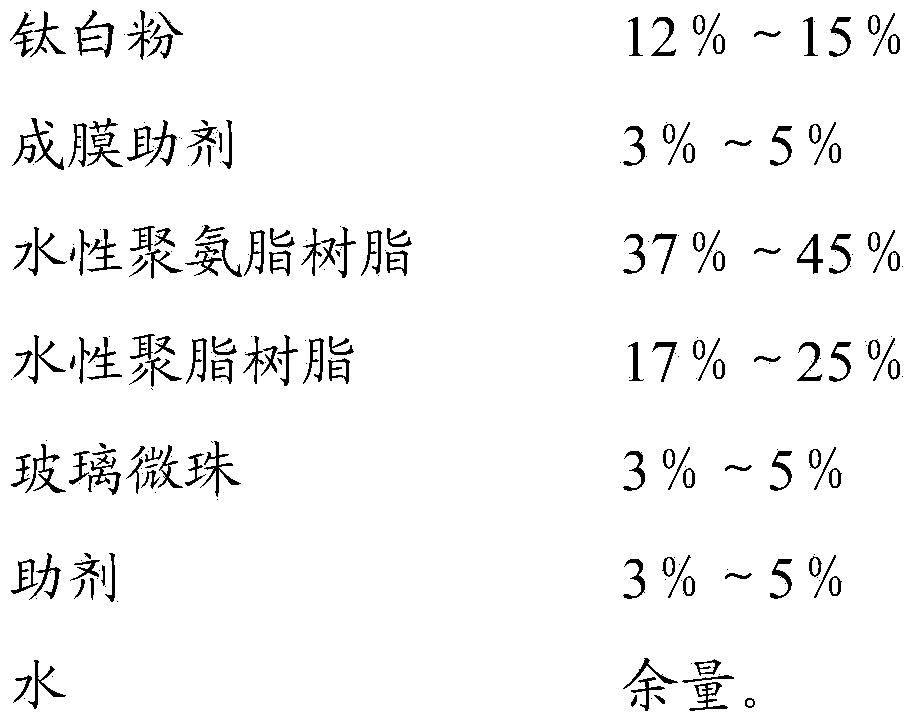

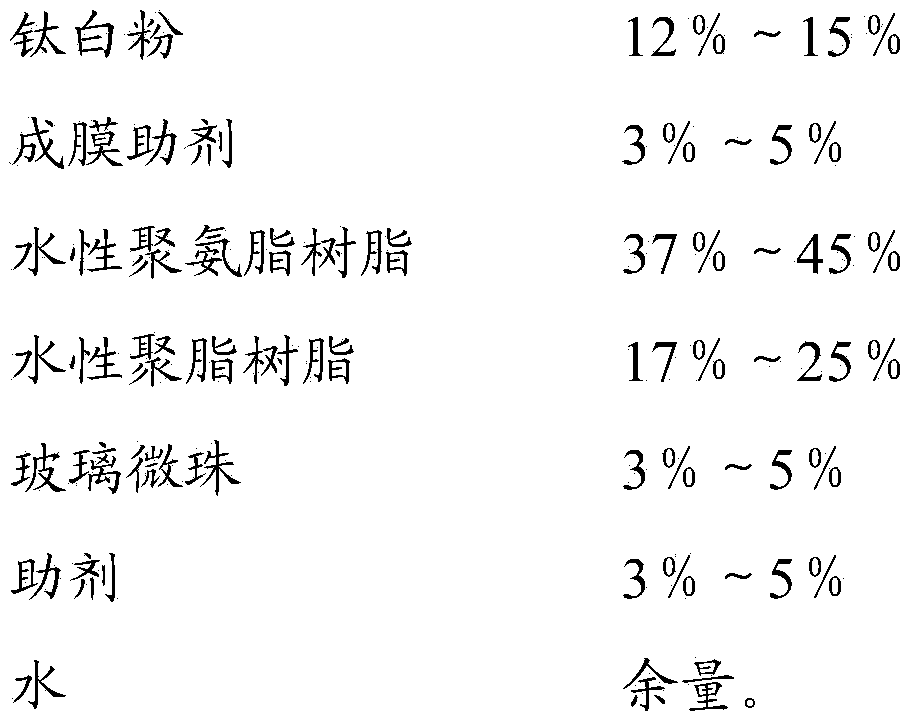

Thermal insulation coating and preparation method thereof

InactiveCN103850122AImprove insulation lifeGood heat insulationFibre treatmentEnvironmental resistanceThermal insulation

The invention relates to the technical field of coatings and particularly relates to a thermal insulation coating for outdoor textiles. The thermal insulation coating comprises 12-15% of titanium dioxide, 3-5% of coalescing agent, 37-45% of waterborne polyurethane resin, 17-25% of waterborne polyester resin, 3-5% of glass beads, 3-5% of auxiliary and water. The substances are added at different times and are prepared into a finished product under the control of different stirring rotation numbers. When coated on a textile, the thermal insulation coating not only has water resistance, ultraviolet resistance and other basic physical and chemical functions, but also is environment-friendly, free of generating organisms harmful to human bodies, particularly favorable in thermal insulation effect and long in thermal insulation life; after the thermal insulation coating is used in a rugged environment for a period of time, the inside and outside thermal insulation difference can be still kept at 23+ / -2 DEG C.

Owner:纪冠峯

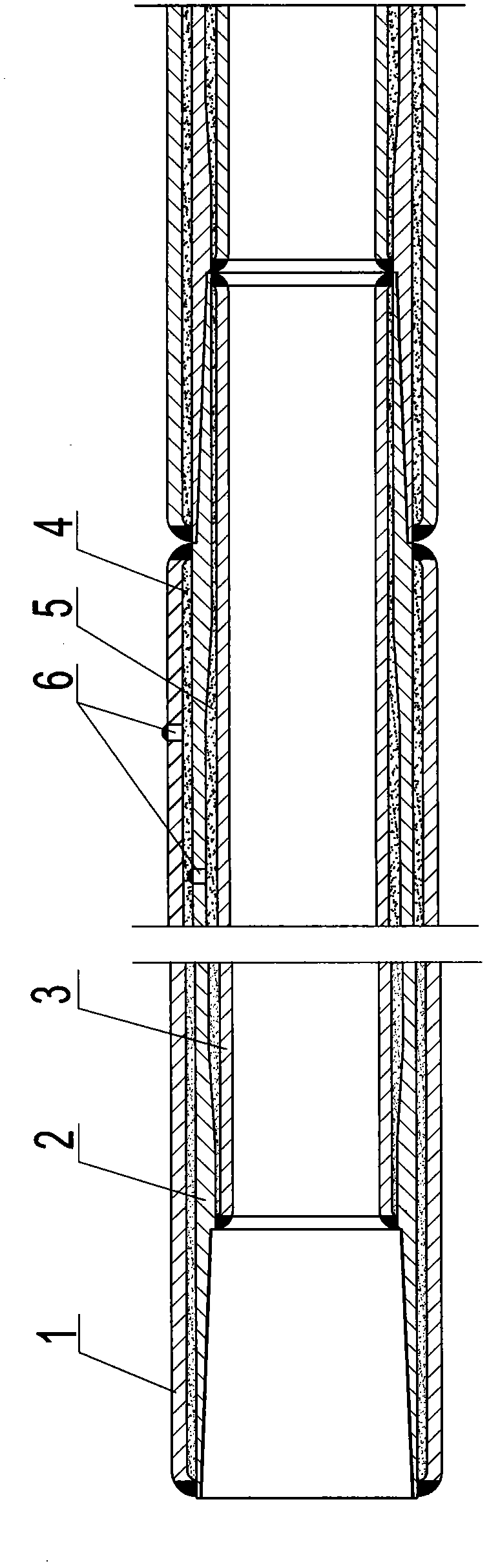

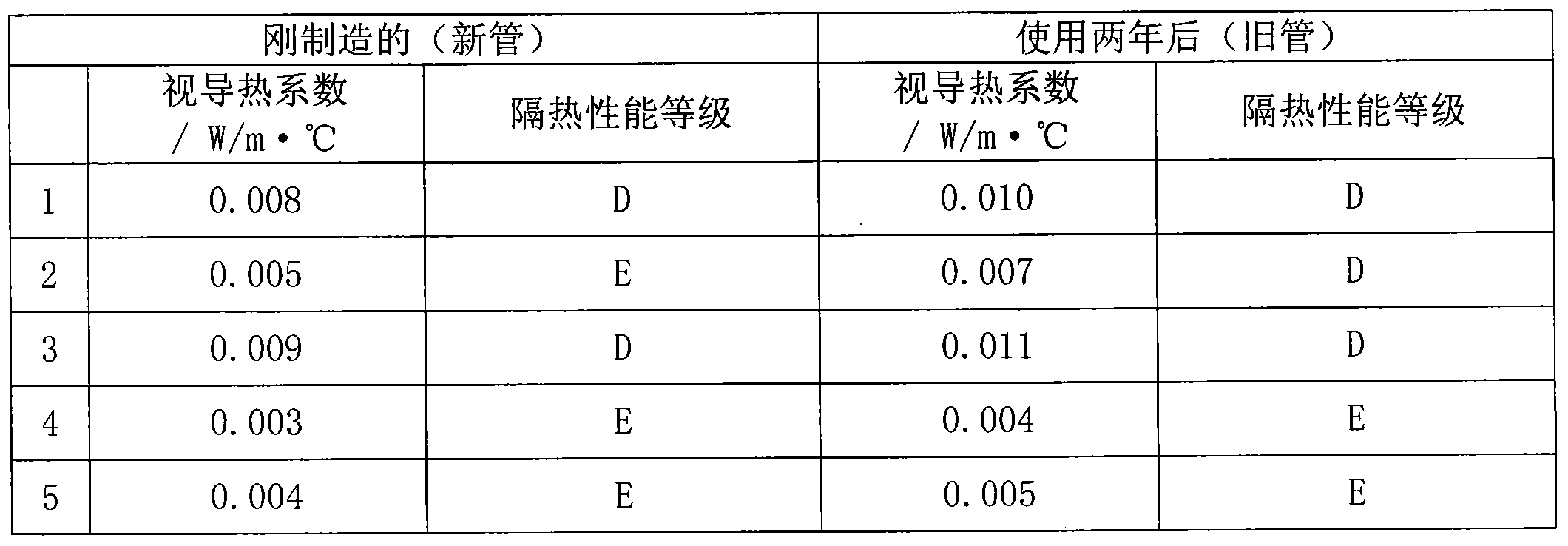

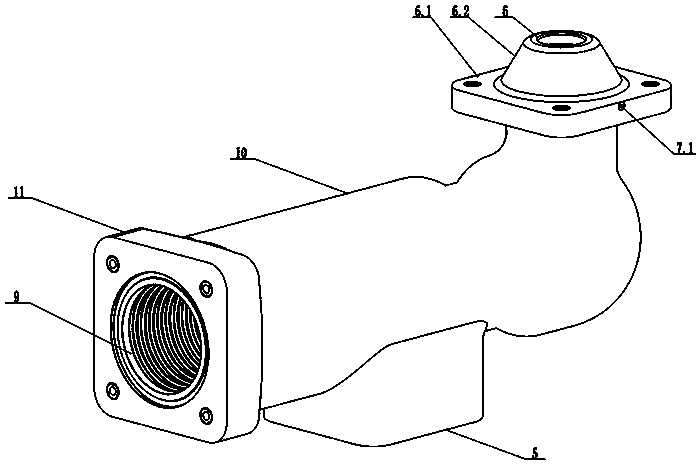

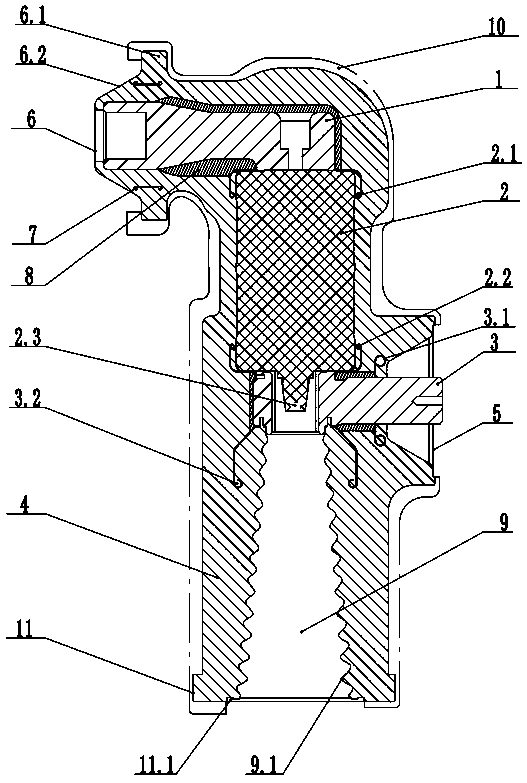

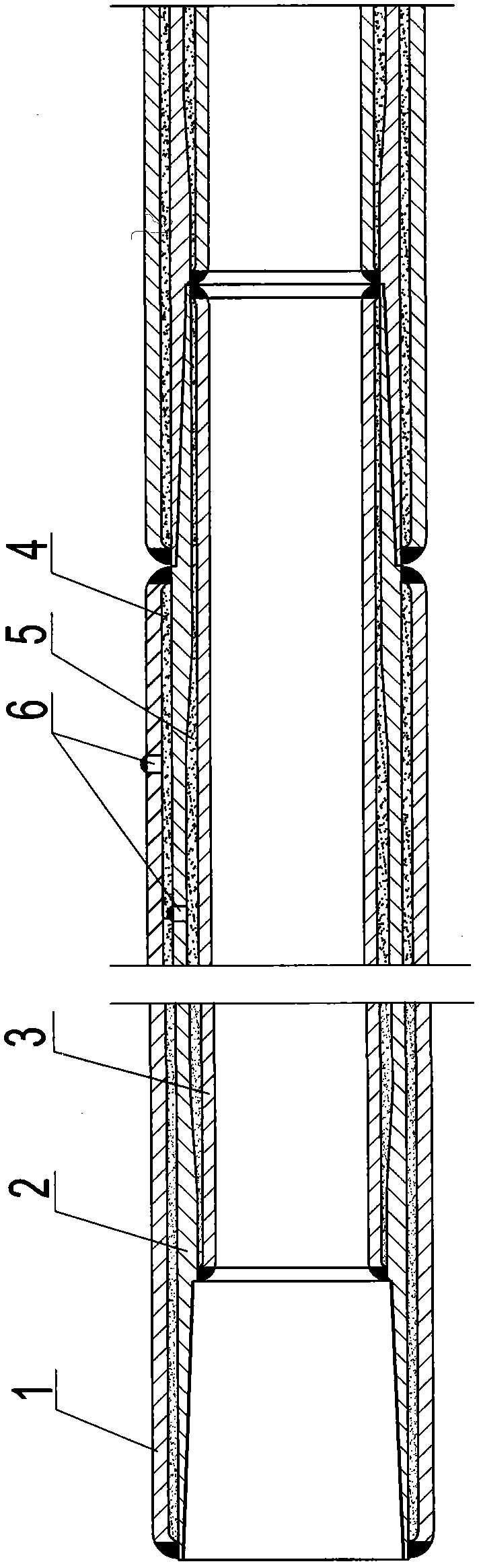

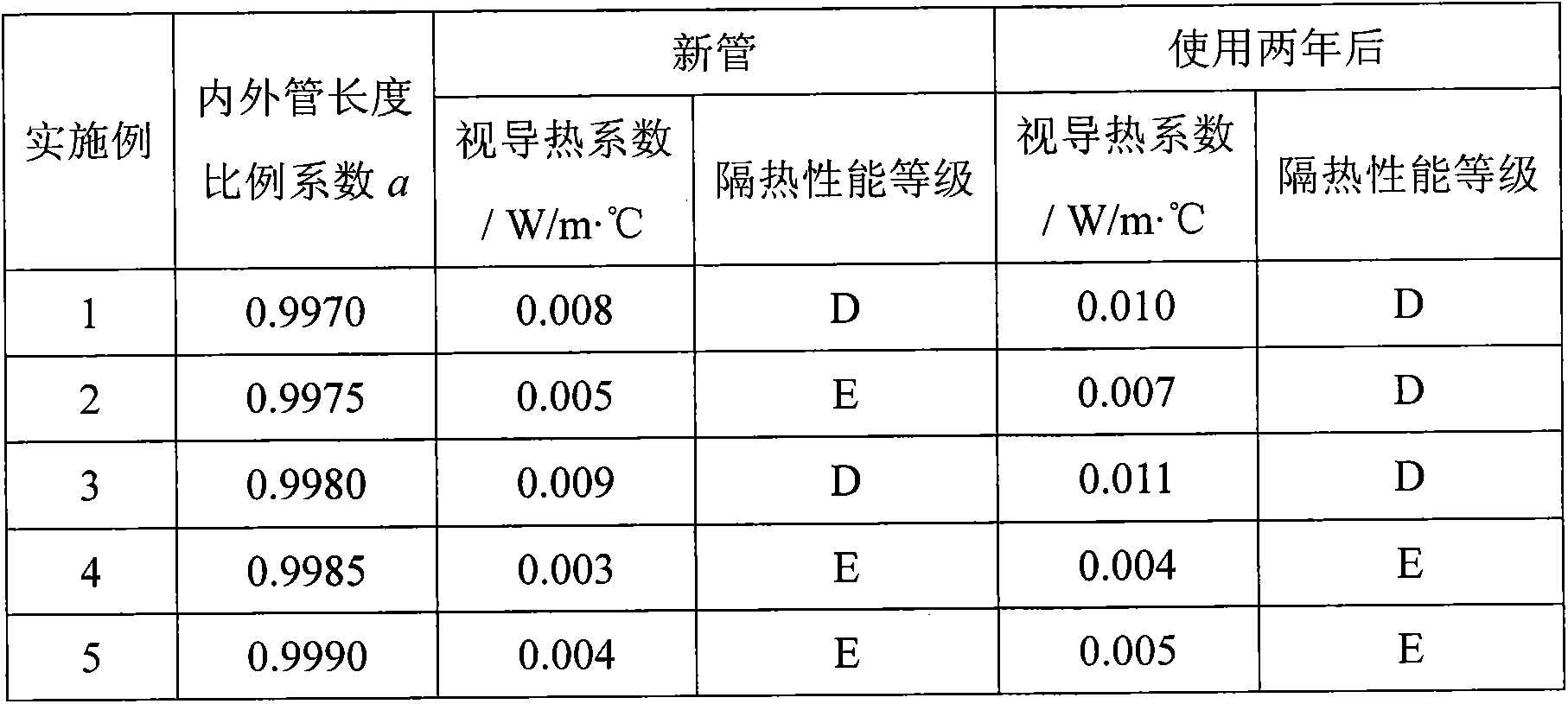

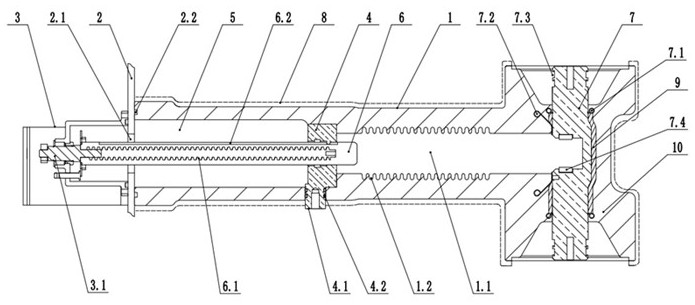

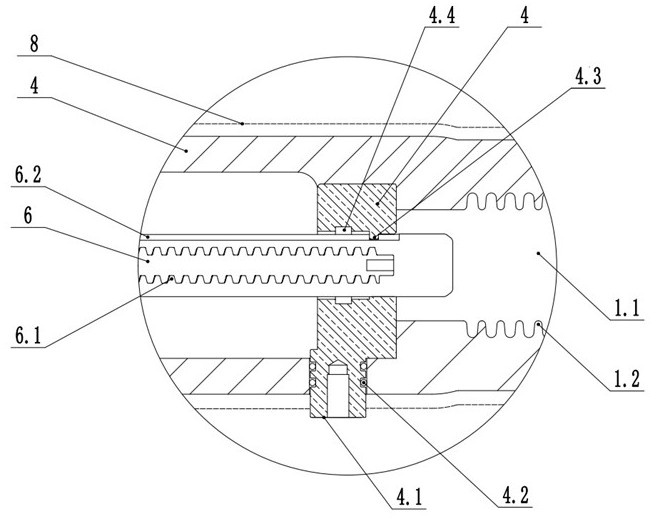

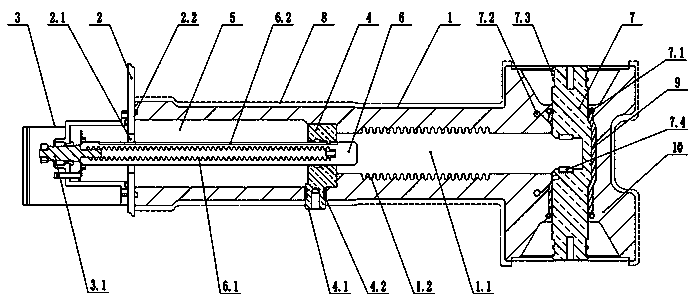

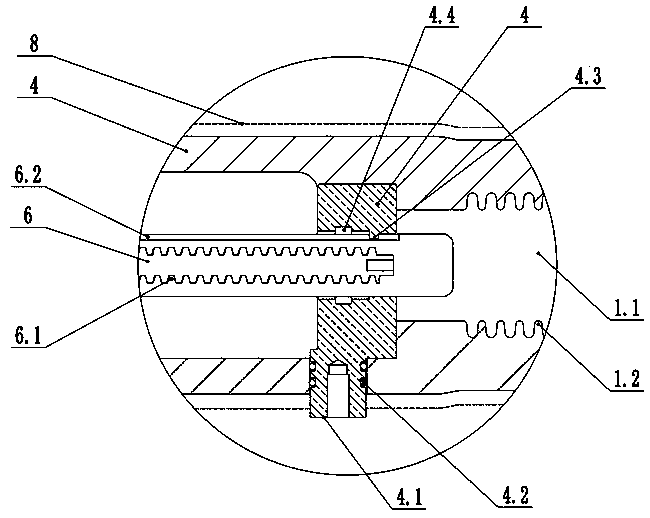

Heat-insulating oil sleeve and manufacturing method thereof

ActiveCN103850653AImprove insulation performanceSlow down the phenomenon of "hydrogen permeation"Drilling rodsDrilling casingsEngineeringScrew thread

The invention relates to a heat-insulating oil sleeve. The heat-insulating oil sleeve is characterized by comprising an outer pipe, an intermediate pipe and an inner pipe which are sleeved in a clearance fit way; internal threads are machined at one end of the intermediate pipe; external threads are machined at the other end of the intermediate pipe; one end, provided with the internal threads, of the intermediate pipe is welded with the outer pipe at a pipe end, and is welded with the inner pipe at the length position of the preserved internal threads; one end, provided with the external threads, of the intermediate pipe is welded with the outer pipe at the length position of the preserved external threads, and is welded with the inner pipe at the pipe end; an annular cavity formed by the outer pipe and the intermediate pipe is filled with a heat-insulating material and is vacuumized to form a first heat-insulating layer; an annular cavity formed between the intermediate pipe and the inner pipe is vacuumized and is injected with inert gas to form a second heat-insulating layer. A manufacturing method for the heat-insulating oil sleeve comprises the following steps in sequence: performing pretreatment on the three pipes, sleeving and welding the inner pipe and the intermediate pipe, treating the annular cavity between the inner pipe and the intermediate pipe, sleeving and welding the outer pipe and the intermediate pipe, treating the annular cavity between the outer pipe and the intermediate pipe, testing an apparent heat conductivity coefficient and machining threads at the two ends of the intermediate pipe. The heat-insulating oil sleeve has a structure with three layers of steel tubes and double layers of heat-insulating layers, high heat insulation performance, long heat insulation life and high performance.

Owner:淄博孚瑞特热能科技有限公司

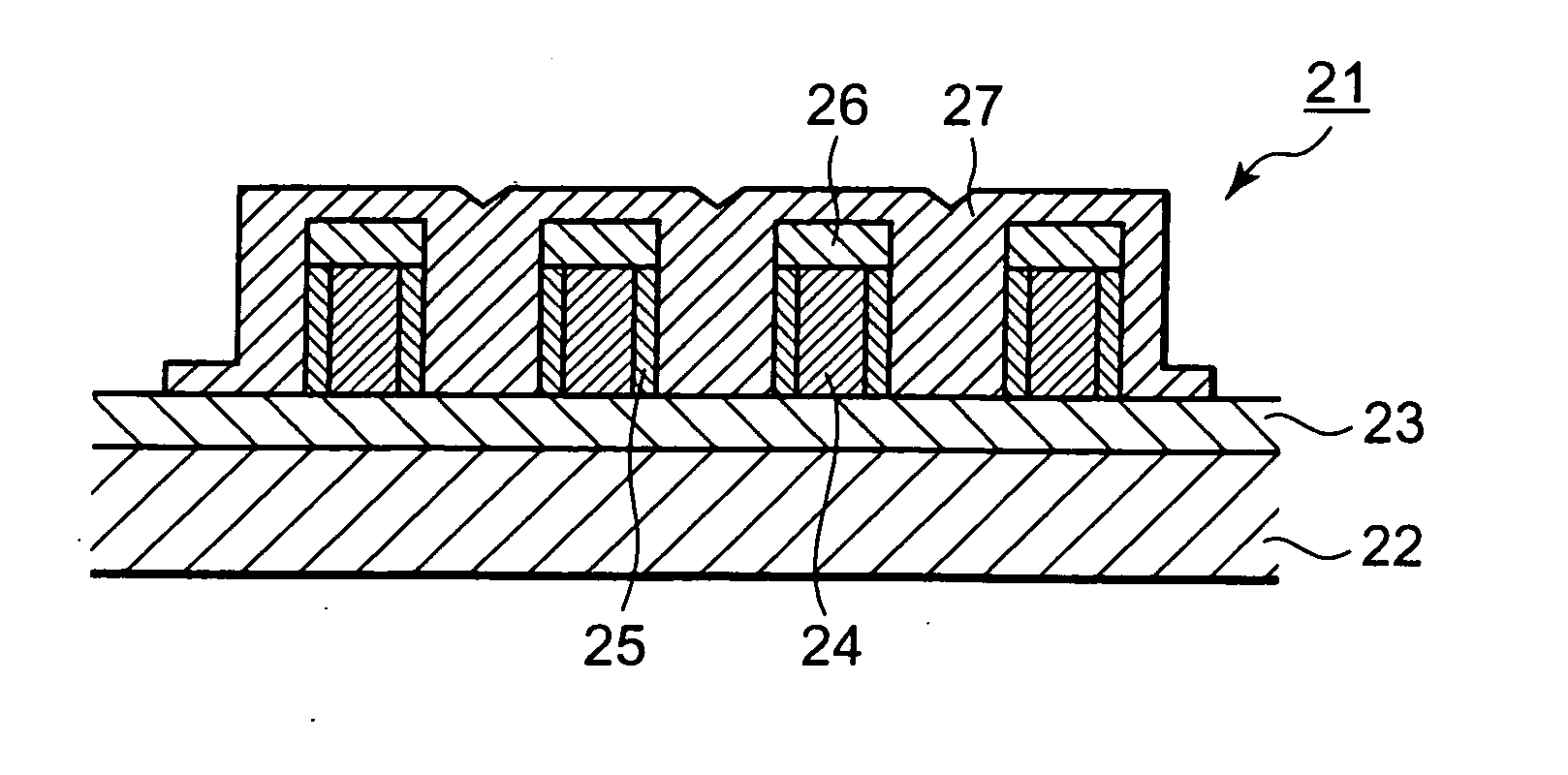

Semiconductor integrated circuit device and method of manufacturing the same

InactiveUS20120153370A1Improve insulation lifeProlong lifeTransistorSolid-state devicesElectrical conductorEngineering

A semiconductor integrated circuit device, includes a first electrode including a first semiconductor layer formed on a substrate, a side surface insulating film formed on at least a part of a side surface of the first electrode, an upper surface insulating film formed on the first electrode and the side surface insulating film, a second electrode which covers the side surface insulating film and the upper surface insulating film, and a fin-type field effect transistor. The first electrode, the side surface insulating film, and the second electrode constitute a capacitor element. A thickness of the upper surface insulating film between the first electrode and the second electrode is larger than a thickness of the side surface insulating film between the first electrode and the second electrode, and the fin-type field effect transistor includes a second semiconductor layer which protrudes with respect to the plane of the substrate.

Owner:RENESAS ELECTRONICS CORP

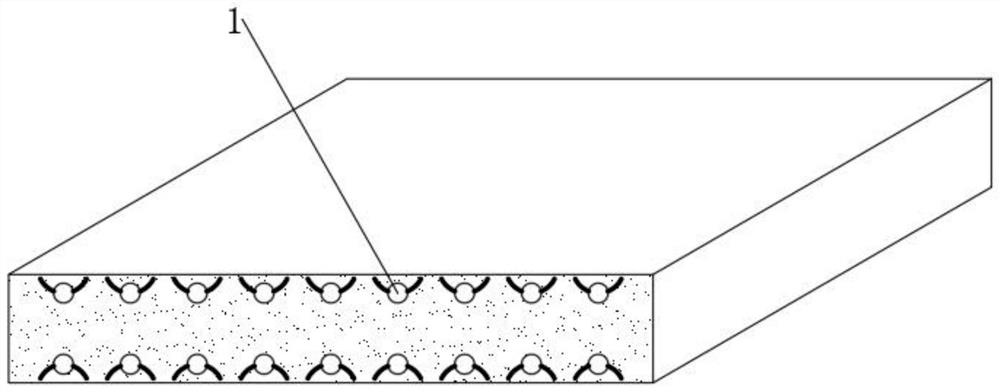

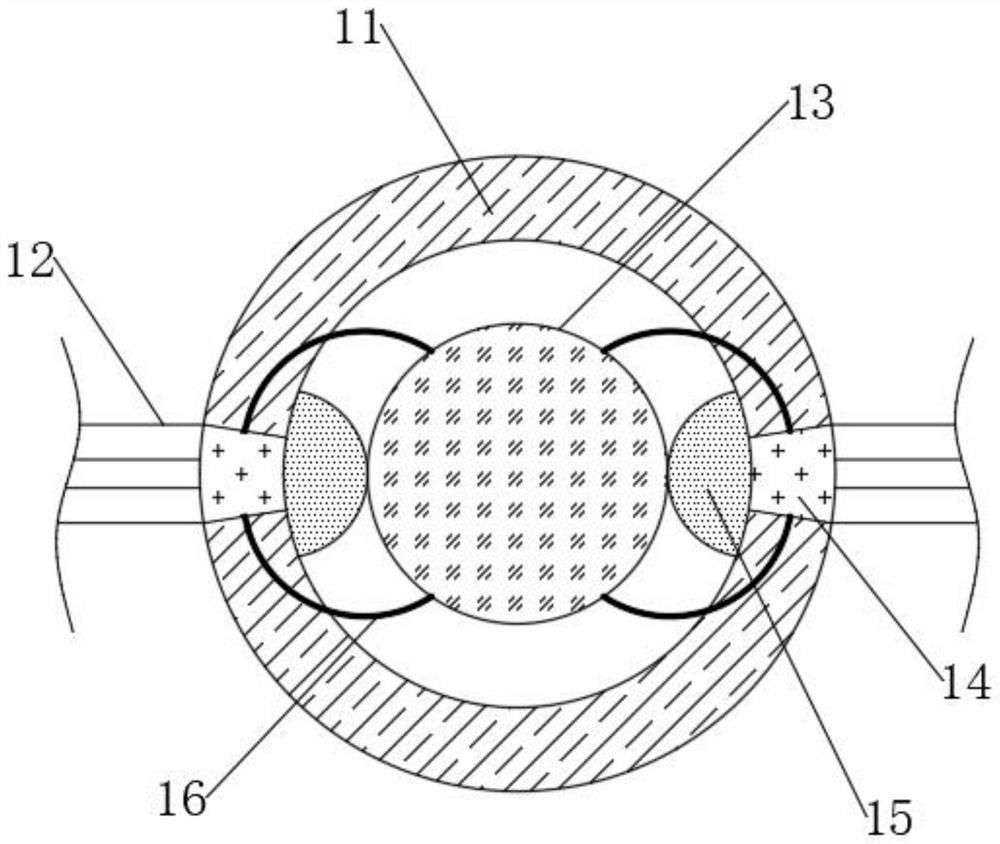

Preparation process of oil bleeding type anti-seepage building insulation board

The invention discloses a preparation process of an oil bleeding type anti-seepage building insulation board, belongs to the technical field of building insulation, and aims to improve the insulationperformance and crack resistance of a concrete insulation board by improving the raw materials of the concrete insulation board and fill hydrophobic and oleophylic organic bentonite to perform overallphysical modification on the insulation board, so that the anti-seepage performance of the insulation board is improved. In addition, a plurality of oil bleeding anti-seepage balls which are uniformly distributed are embedded in the position, which is close to the surface, of the interior of the insulation board in advance, the oil bleeding action in the oil bleeding anti-seepage balls is triggered by sensing the water seepage phenomenon, and oil wrapping belt water-repellent microspheres are forced to carry out reverse filling along a water seepage path. By means of the action that the water-repellent microspheres decompose when encountering water, permeation water is repelled, and oil is dispersed through the oleophylic characteristic of the insulation board at the same time, so that seepage prevention treatment and blocking treatment are conducted on a seepage area, permeation water can be effectively prevented from further diffusing and going deep, finally, seepage prevention protection of the insulation board is achieved, and the heat preservation service life of the insulation board is prolonged.

Owner:陈志辉

Insulating film

InactiveCN103858179AImprove heat resistanceImprove insulation lifePlastic/resin/waxes insulatorsInsulated cablesHeat resistancePolymer chemistry

Owner:NITTO DENKO CORP

Heat insulation composition

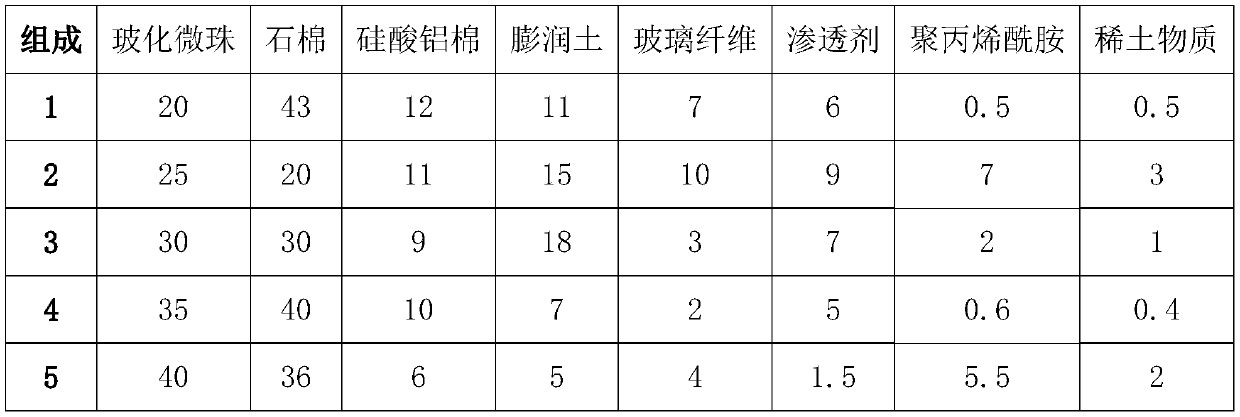

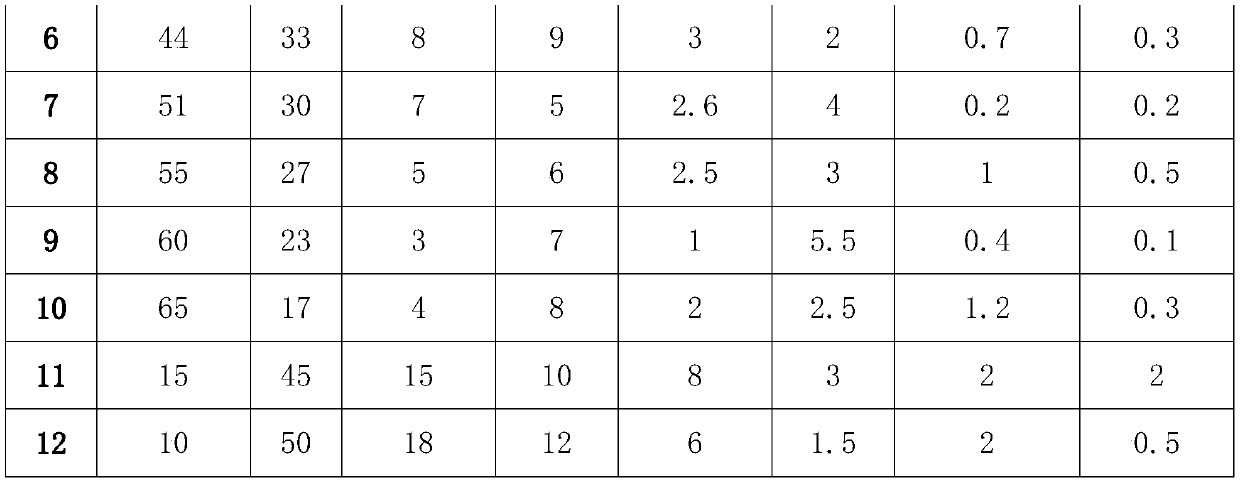

PendingCN110498636AExtended heat conduction pathLow thermal conductivityGlass fiberAluminum silicate

The invention discloses a heat insulation composition with a heat insulation effect. The problem that the volume weight of the heat preservation composition is large when the heat insulation effect isimproved in the prior art is solved. The heat insulation composition comprises 10-65 wt% of vitrified microbeads, 10-50 wt% of asbestos, 1-20 wt% of aluminum silicate wool, 5-20 wt% of bentonite, 1-10 wt% of glass fibers and 1-10 wt% of a penetrant. The heat insulation composition has the advantages of excellent heat insulation performance, low volume weight, reduction of the thickness by 50% orabove under a condition that the surface temperature is same to that of the aluminum silicate wool, and remarkable energy-saving effect due to great reduction of the heat dissipation area, so the adiabatic temperature range is greatly expanded, and the working temperature range can reach -40-1000 DEG C.

Owner:刘永平

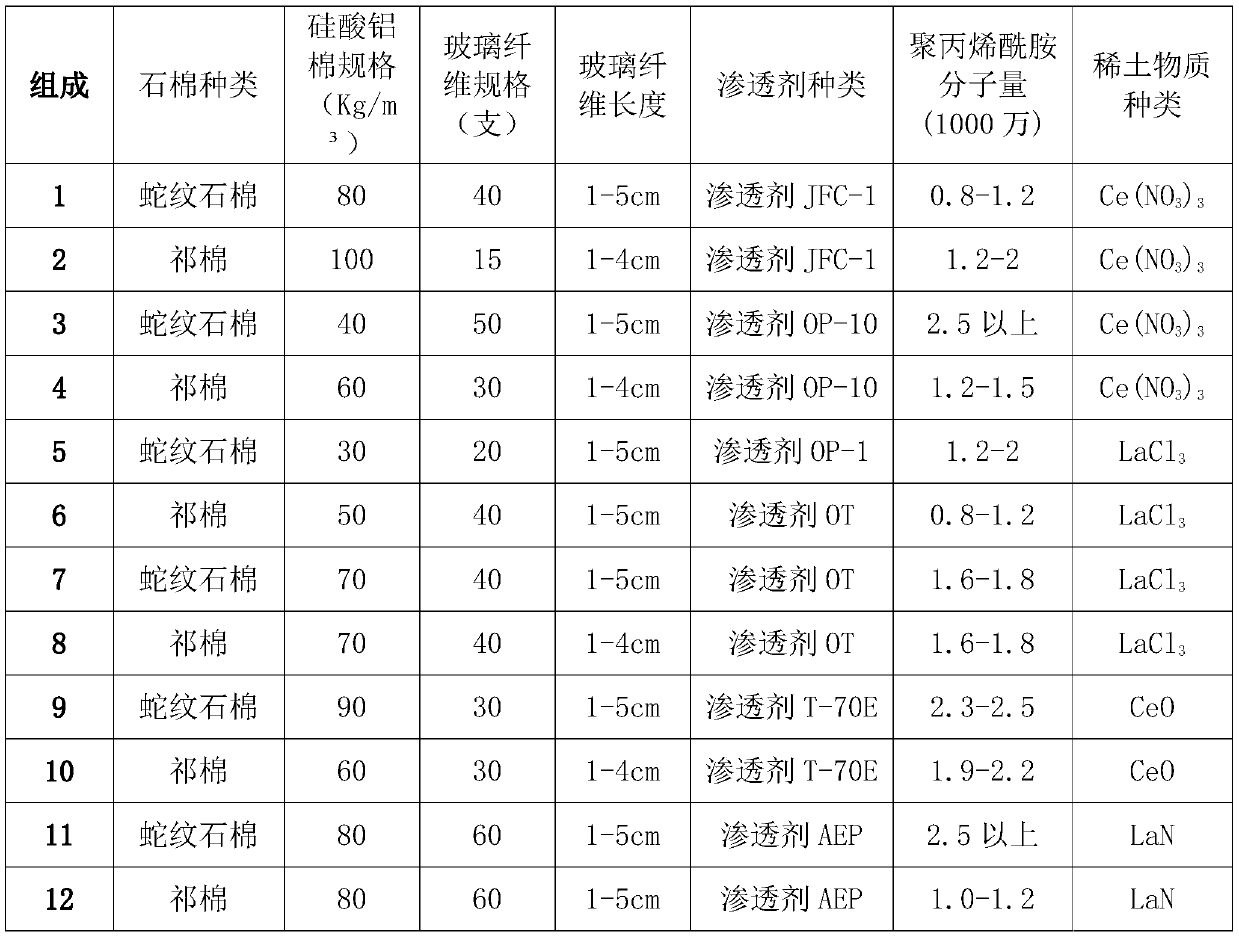

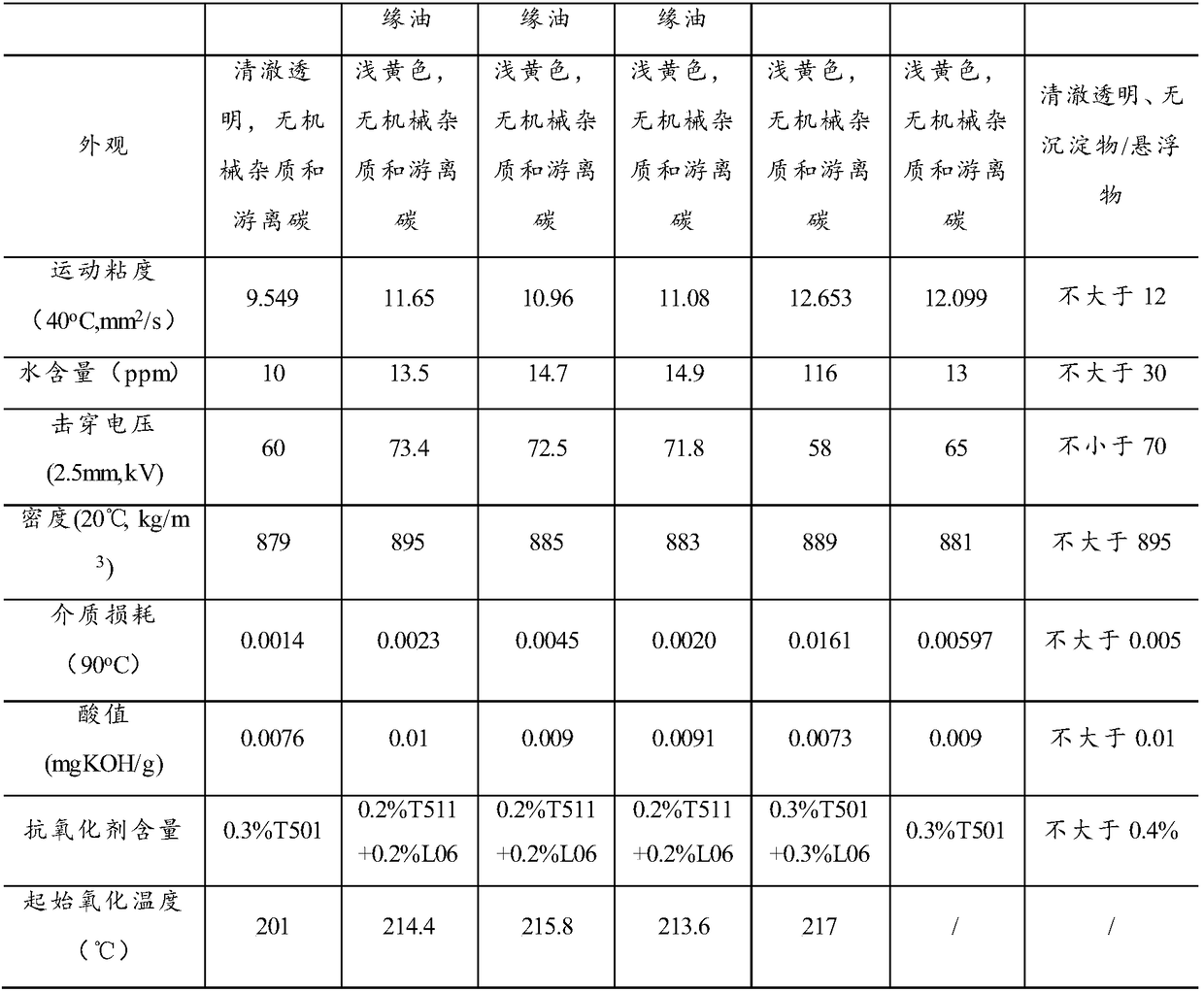

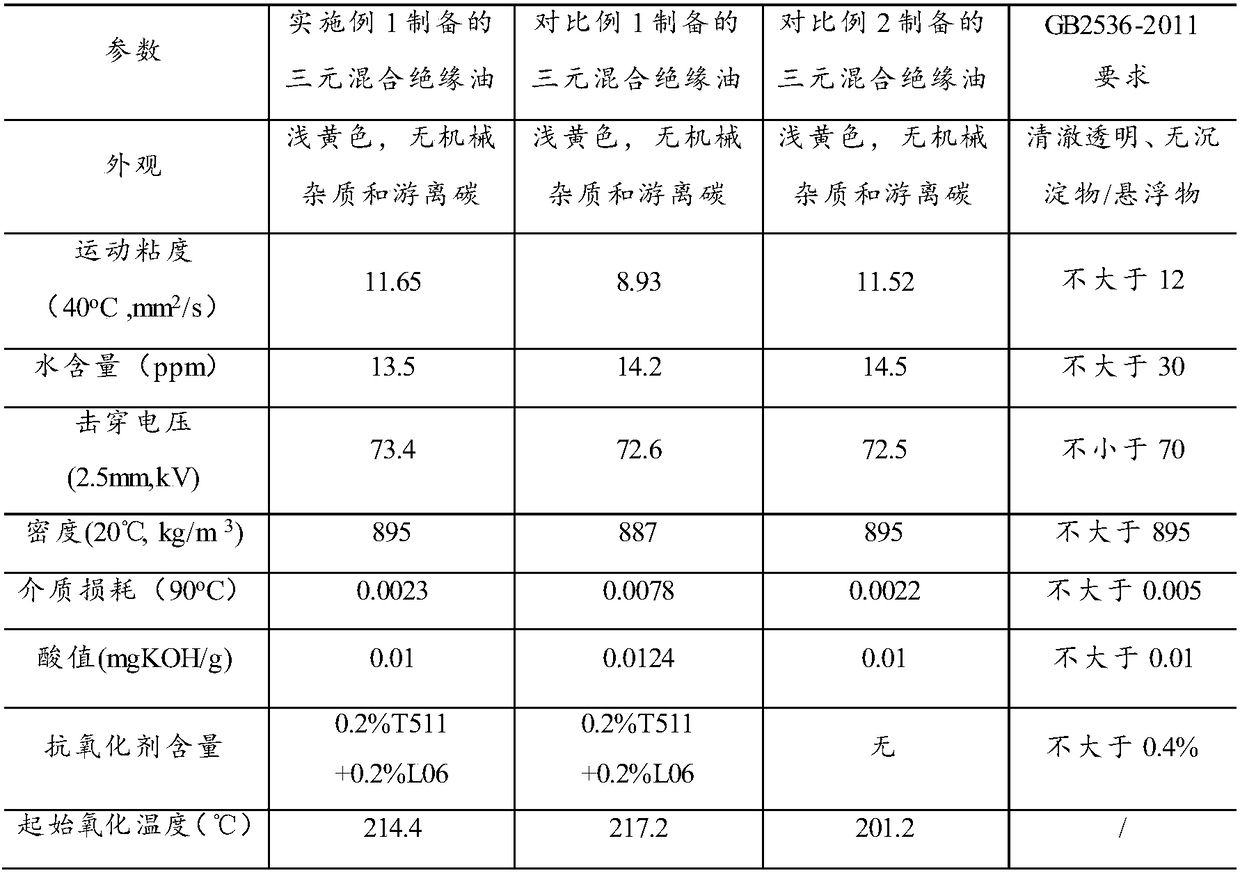

Ternary mixed insulation oil and preparation method thereof

ActiveCN108130176AImprove cooling effectLower operating temperatureLubricant compositionAntioxidantMass ratio

The invention provides a ternary mixed insulation oil and a preparation method thereof. The ternary mixed insulation oil is prepared from base oil and an antioxidant with the mass ratio being 100:0.05to 0.4; the base oil is prepared from the components in percentage by mass: 10 to 25 percent of soybean oil, 3 to 10 percent of palm oil, and 70 to 87 percent of mineral oil; the antioxidant is selected from a phenolic oxidizing agent and / or an amine oxidizing agent. The ternary mixed insulation oil has lower kinematic viscosity and dielectric loss compared with traditional mixed insulation oil so as to have more superior heat dissipation performance, so that a transformer oil paper insulation system has lower operating temperature under the same operating load. The ternary mixed insulation oil has higher power frequency breakdown voltage. The ageing rate of the oil paper insulation system can be effectively retarded, the insulation life of oil paper insulation electrical equipment is prolonged, and the ternary mixed insulation oil has a more excellent environmental protection performance and oil paper insulation system matchability.

Owner:CHONGQING UNIV +1

High-heat-conductivity insulating structure and manufacturing method thereof

ActiveCN104795923AImprove thermal efficiencyReduce operating temperature riseWindings insulation materialWindings insulation shape/form/constructionMicaVarnish

The invention discloses a high-heat-conductivity insulating structure and a manufacturing method thereof. The high-heat-conductivity insulating structure comprises an iron core and an electromagnetic wire embedded in the iron core, a heat conducting film, a mica tape and an alkali-free glass tape are sequentially arranged between the electromagnetic wire and the iron core, an opening of the iron core is sealed by a slot wedge, and an inner gap of the iron core is provided with dipping varnish by means of dipping. The high-heat-conductivity insulating structure has the advantages that due to the fact that the heat conducting film, the mica tape and the alkali-free glass tape are sequentially arranged between the electromagnetic wire and the iron core to form a heat conducting passage in the whole insulating structure, internal heat conducting efficiency of a motor is improved, heat in the motor can be transferred to a cooling medium more quickly, and accordingly operation rise of the motor can be lowered to realize cooling of an insulation operation environment so as to prolong insulation service life of the motor.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

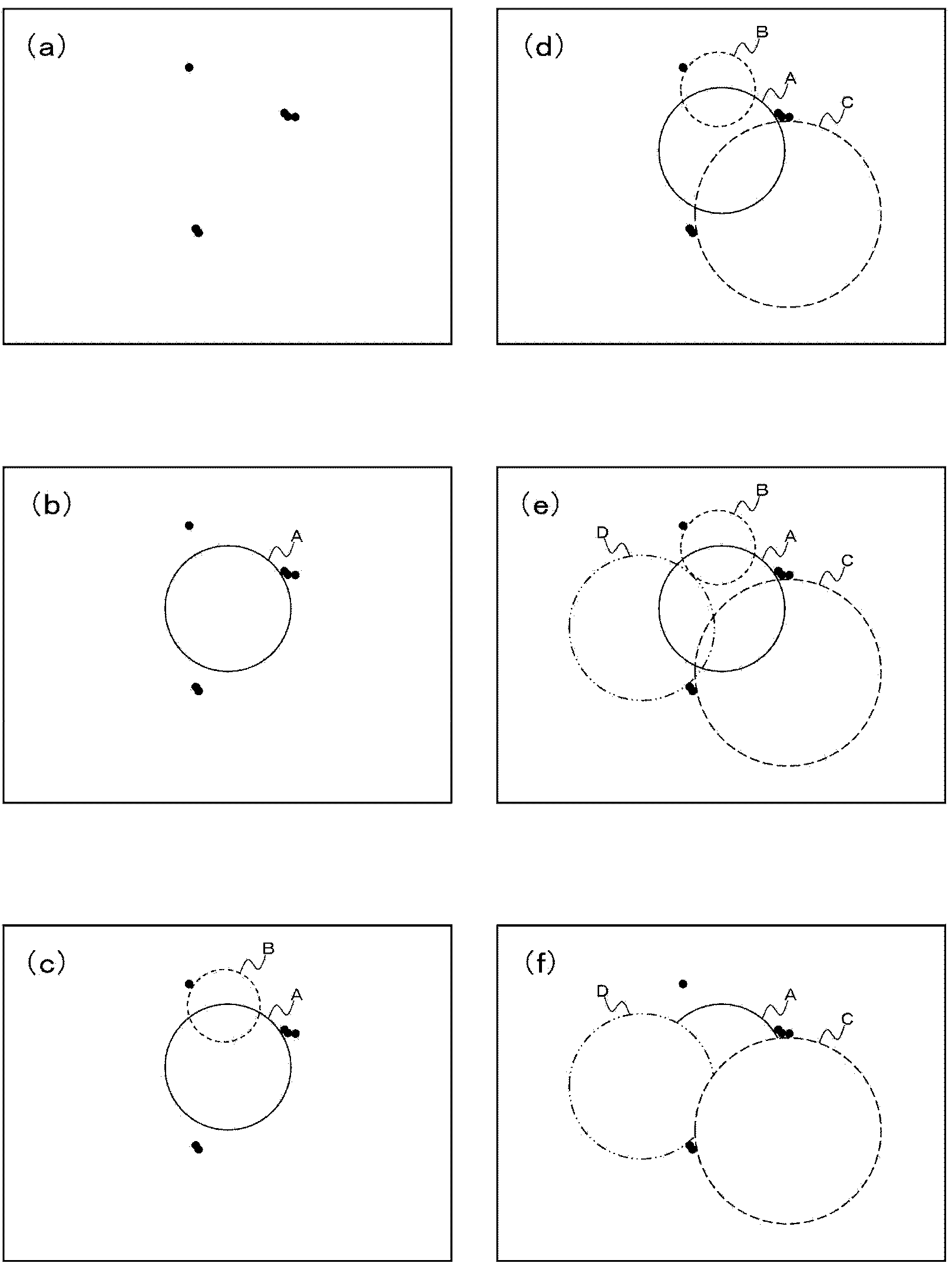

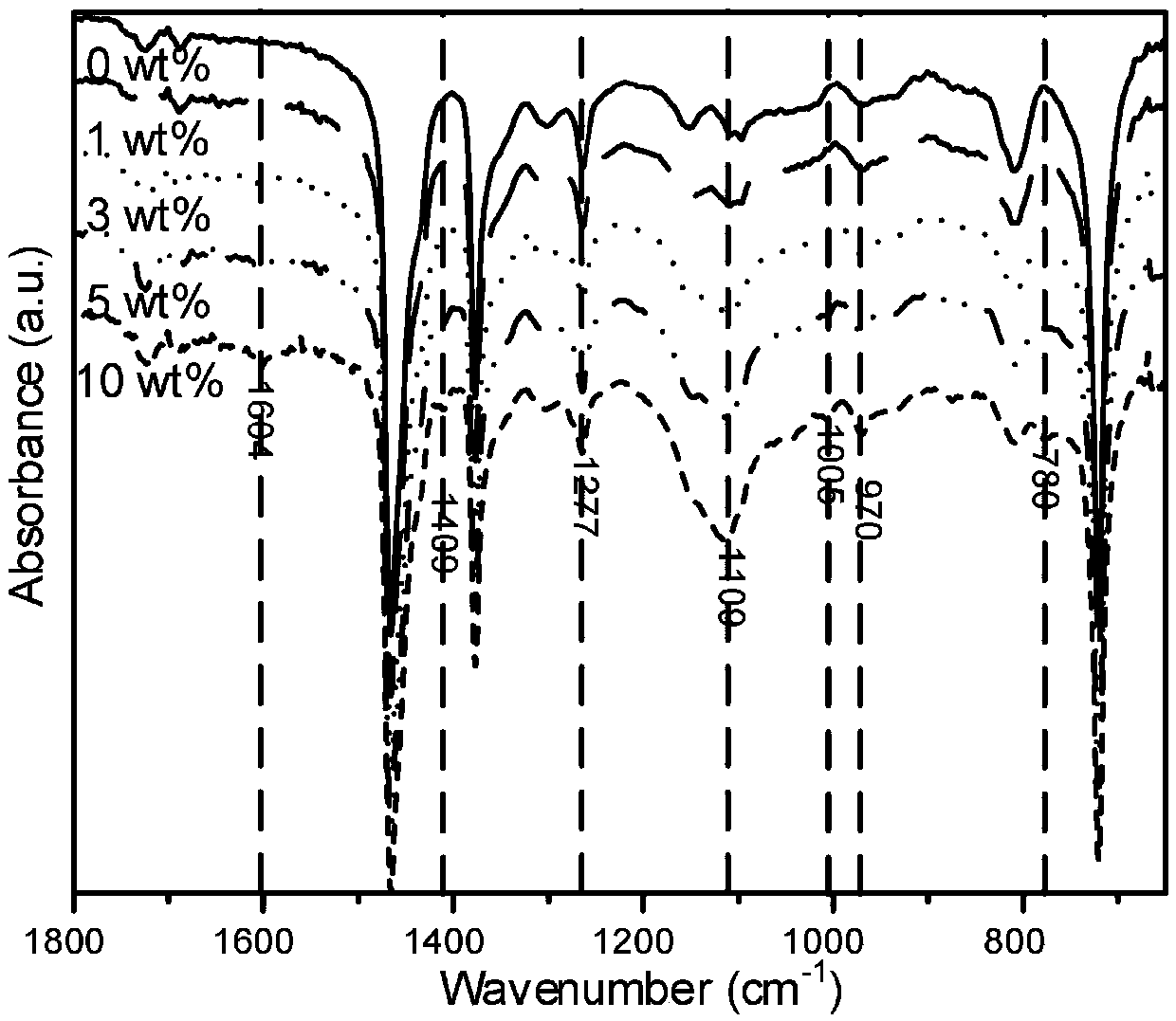

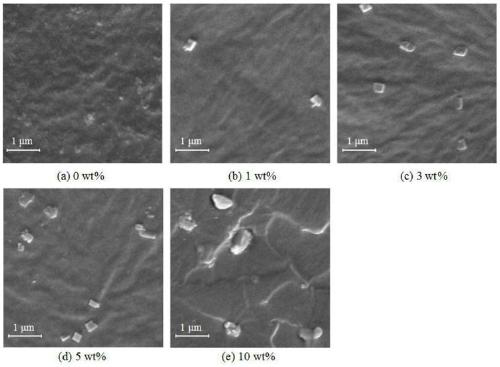

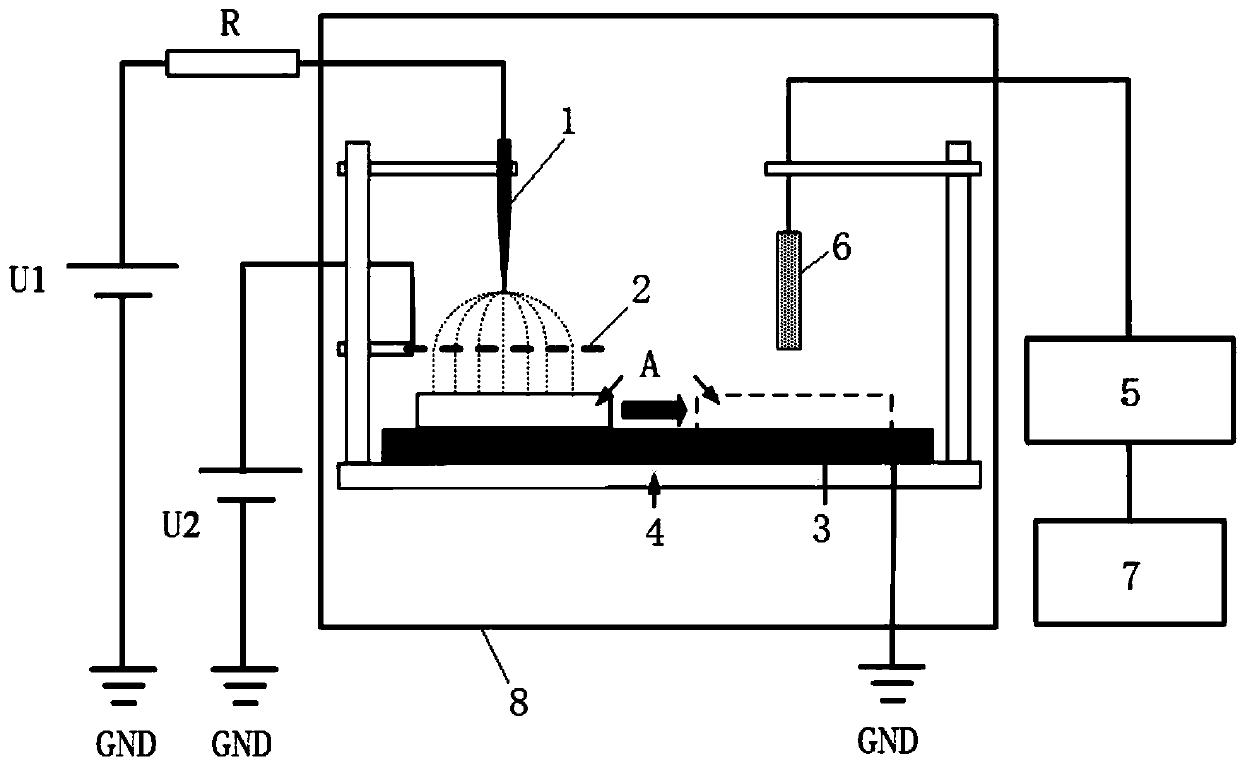

Trap regulation and control method based on POSS modified terpolymer ethylene propylene rubber

InactiveCN109251423AImprove insulation lifeReduced effective mobilityRubber insulatorsRubber materialPolymer science

The invention discloses a trap regulation and control method based on POSS modified terpolymer ethylene propylene rubber. The trap regulation and control method based on POSS modified terpolymer ethylene propylene rubber comprises following steps: OVPOSS nanometer material is dried to remove water; a double-roller mixing mill roller is heated, roller distance and blocking plate distance are adjusted, terpolymer ethylene propylene rubber is introduced into the double-roller mixing mill roller for mix milling, an obtained product is taken out from the double-roller mixing mill roller, and the double rollers are washed; terpolymer ethylene propylene raw rubber is introduced for mix milling and roll banding; OVPOSS nanometer is added into terpolymer ethylene propylene rubber matrix for mix milling; 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane is weighed, and is introduced into the double-roller mixing mill for mix milling so as to obtain an unvulcanized rubber material; the unvulcanized rubber material is taken out from the double-roller mixing mill, is placed between two layers of PET film, is introduced into a high temperature hot processing forming machine die for hot pressing, and obtained rubber sheets are taken out from the high temerpature hot processing forming machine die after cooling; the rubber sheets are suspended in an air blast baking oven, sulfuration is carried outso as to obtain modified terpolymer ethylene propylene rubber sample sheets; the functional group composition and section morphology of the modified terpolymer ethylene propylene rubber sample sheetsare analyzed; rubber sample sheet surface potential attenuation characteristics are measured; SPD method is adopted to obtain trap distribution character diagram and charge mobility characteristics ofthe rubber.

Owner:TIANJIN UNIV

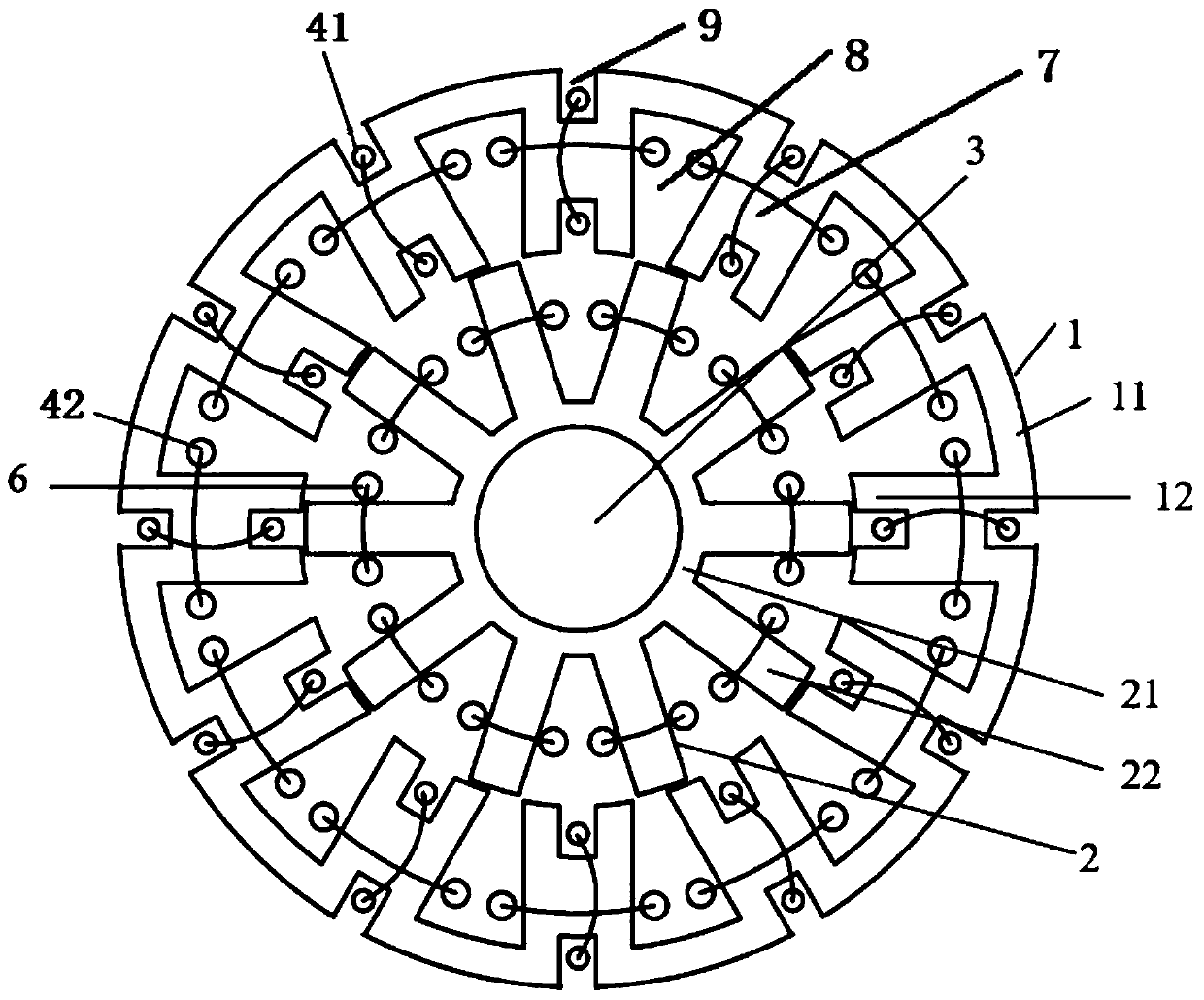

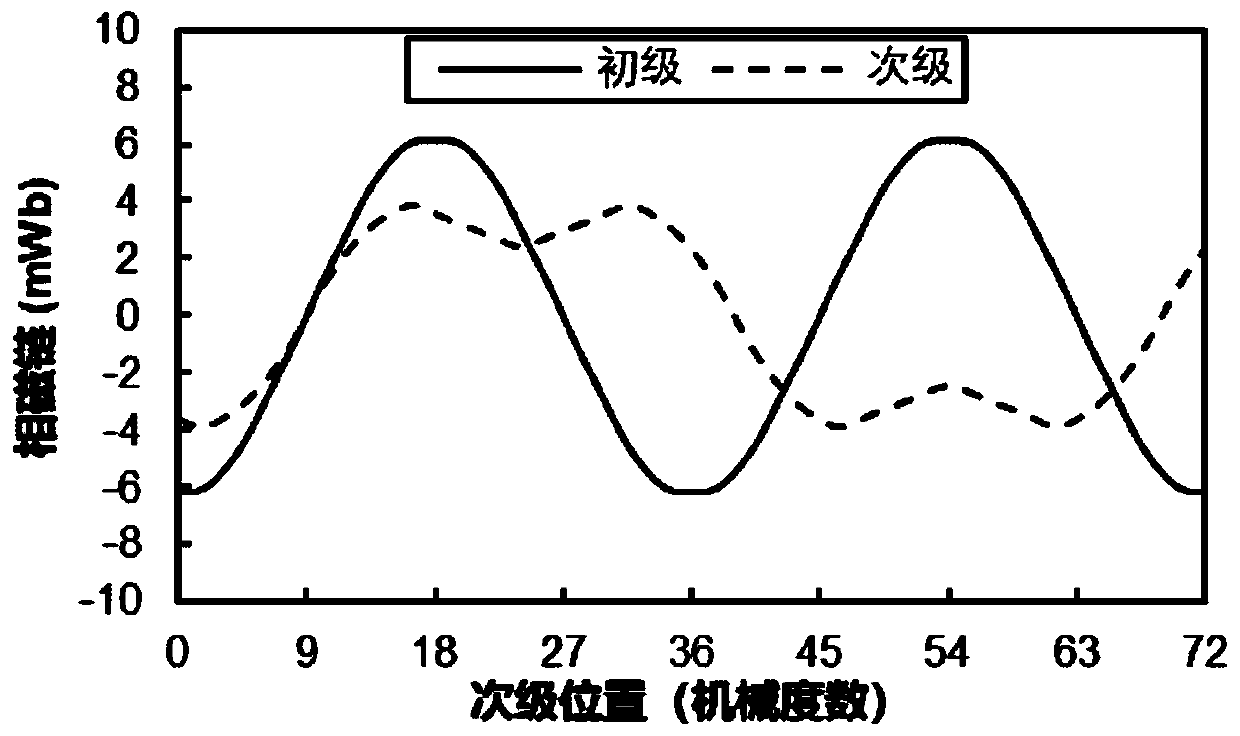

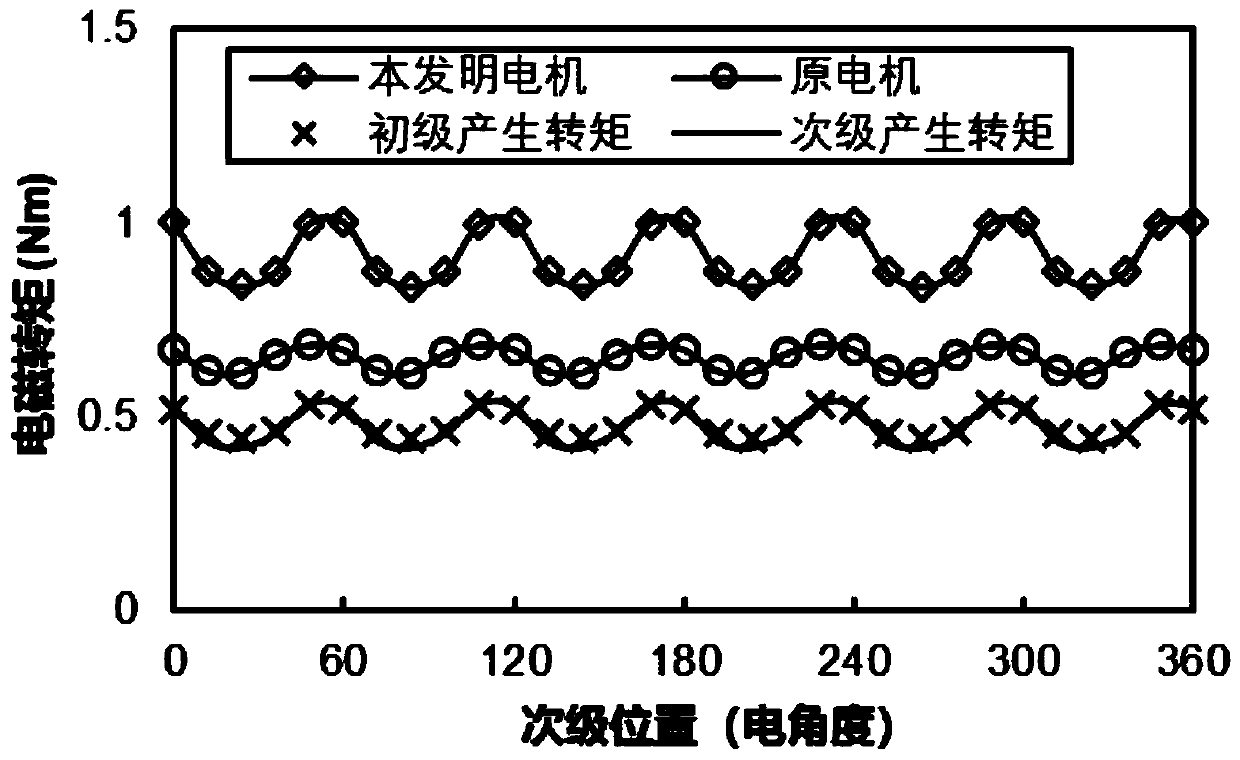

Double-fed type electrically excited synchronous motor

ActiveCN110071614AIncreased torque densityCompact structureAssociation with control/drive circuitsSynchronous motorsSynchronous motorConductor Coil

The invention discloses a double-fed type electrically excited synchronous motor. The double-fed type electrically excited synchronous motor comprises a primary unit and a secondary unit which are both of salient pole structures; the primary unit comprises a primary iron core and a primary winding; the primary iron core comprises primary iron core teeth and a primary iron core yoke; the primary winding is arranged in a primary iron core groove formed between the primary iron core teeth; the primary winding comprises an excitation winding and an armature winding; the secondary unit comprises asecondary iron core; the secondary iron core comprises secondary iron core teeth and a secondary iron core yoke; the secondary unit further comprises a secondary winding; the secondary winding is arranged in a secondary iron core groove formed between the secondary iron core teeth; and the secondary winding comprises a secondary armature winding. According to the double-fed type electrically excited synchronous motor, on the basis that the size of an original motor is not changed, an excitation magnetic field is generated through the excitation winding, and the rotor groove space of the motoris fully utilized for mounting the secondary winding, so that the motor is provided with the primary winding and the secondary winding, and the power density and the regulation and control flexibilityof the motor are improved.

Owner:ZHEJIANG UNIV

Insulating mineral oil for cooling lithium batteries and preparation method of insulating mineral oil

InactiveCN108841433AImprove cooling effectLower operating temperatureLubricant compositionMass ratioButylated hydroxytoluene

The invention provides insulating mineral oil for cooling lithium batteries and a preparation method of the insulating mineral oil. The insulating mineral oil comprises base oil and an antioxidant; the base oil comprises the following components in percentage by mass: 15-30% soybean oil, 1-7% palm oil and 65-82% mineral oil; and the antioxidant comprises glyceride and at least one of the followingcomponents: tertiary butylhydroquinone (TBHQ), butylated hydroxytoluene (BHT) and propyl gallate (PG), wherein the percentage between the mass of each component and the total mass satisfies the following relationships: the TBHQ with mass ratio below 15%, the BHT with mass ratio below 5%, the PG with mass ratio below 5% and the glyceride with mass ratio above 90%. The insulating mineral oil used for cooling the lithium batteries is lower in kinetic viscosity and dielectric loss as compared to the traditional mixed insulating oil, and therefore the insulating oil has better heat dissipation performance, and the oil-paper insulating systems of the lithium batteries have lower operating temperature under the same operating load.

Owner:南通鼎鑫电池有限公司

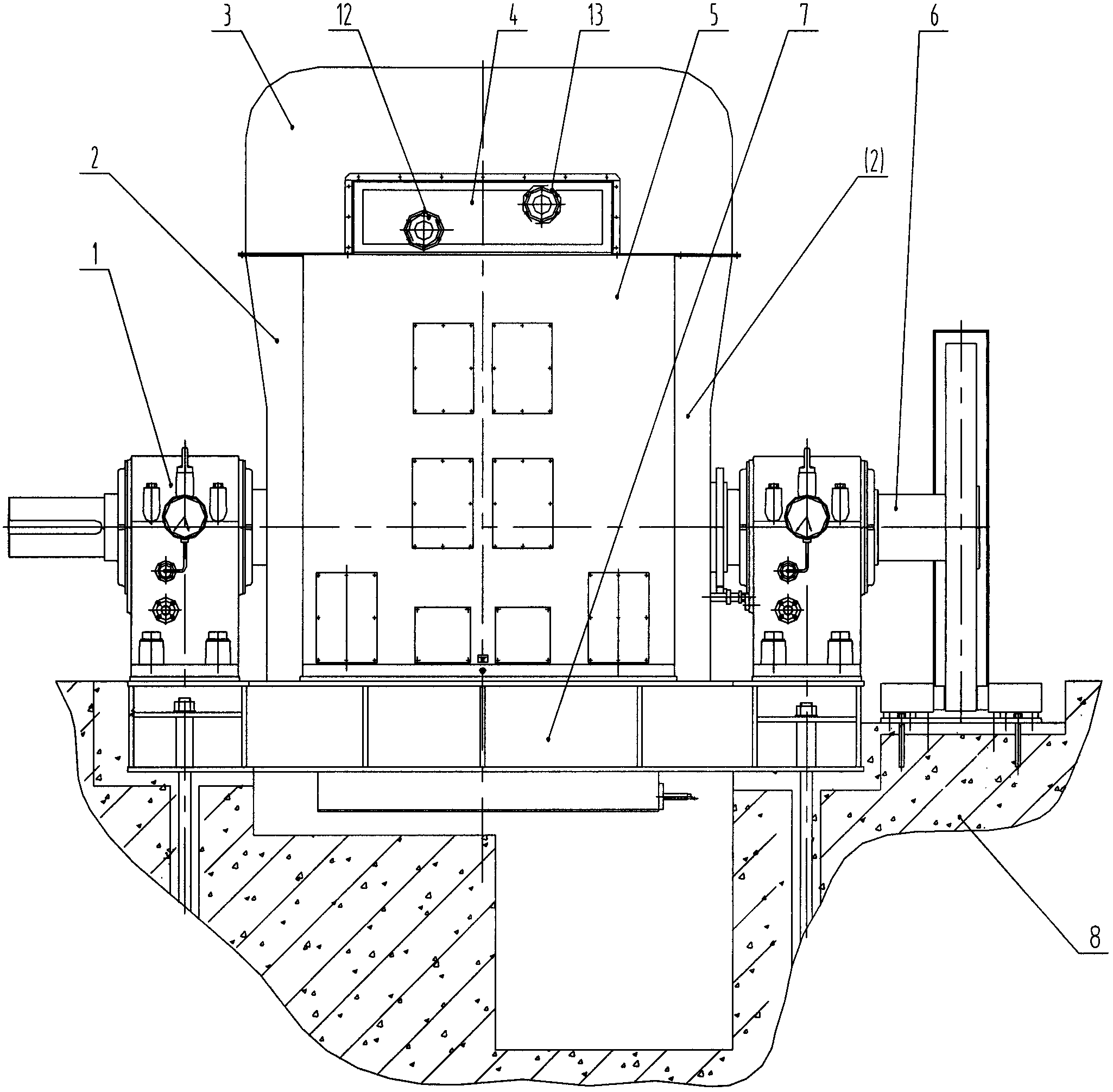

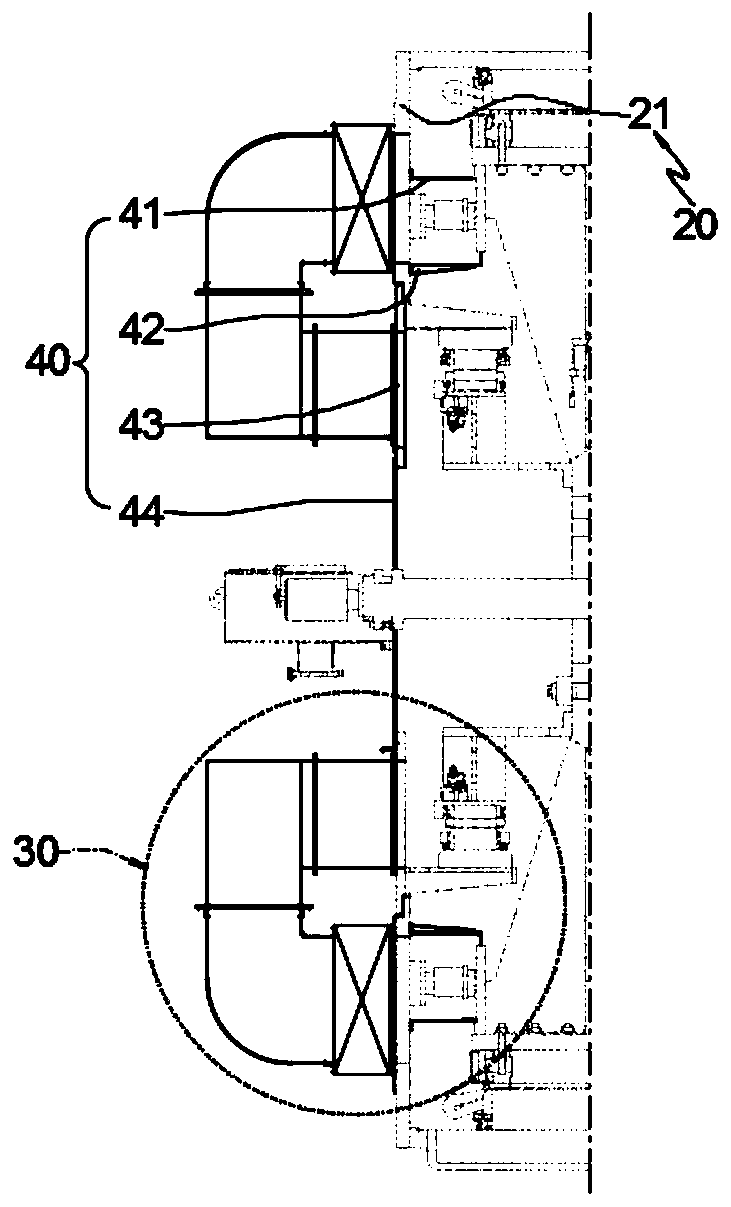

Shaft extension tubular hydrogenerator

InactiveCN102840085ACompact structureReduce excavationMachines/enginesEngine componentsCold airRotation - action

The invention relates to a hydrogenerator, in particular to a shaft extension tubular hydrogenerator. The shaft extension tubular hydrogenerator comprises a rotor, a stator, left and right hoods, an air cooler, a pedestal bearing, a base and an upper hood, wherein the air cooler is placed at the top of the stator; the left and the right hoods are positioned on the two sides of the stator; and the upper hood is positioned at the upper parts of the stator and the left and the right hoods. Air is sealed in an enclosed space formed by the upper hood, the left and the right hoods, the stator and the rotator; and under the rotation action of the fan of the rotor, the circulation line of the air is: the rotor - the stator - the air cooler - the upper hood - the left-right hood - the rotor. According to the shaft extension tubular hydrogenerator, the structure is compact; the cold air is stable and low in temperature and the cooling effect is good due to the adoption of the air cooler for heat exchange; the air is clean, dry and pollution-free; the generator is low in noise; the air cooler is convenient and simple to mount and maintain and not limited by the space; and the workshop foundation is small in excavated volume and low in cost.

Owner:潮州市汇能电机有限公司

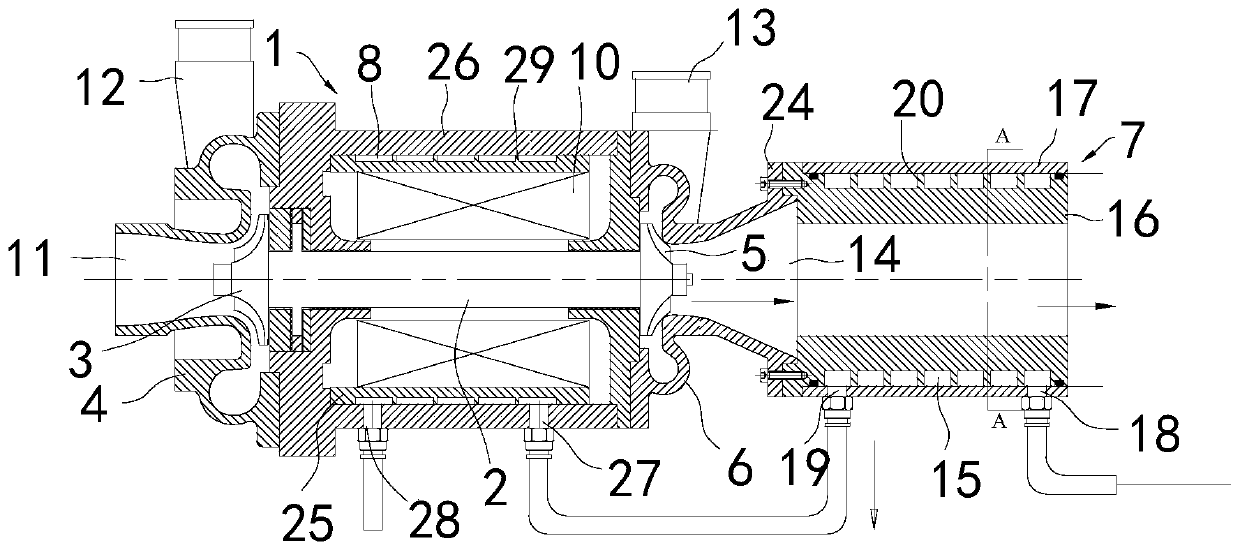

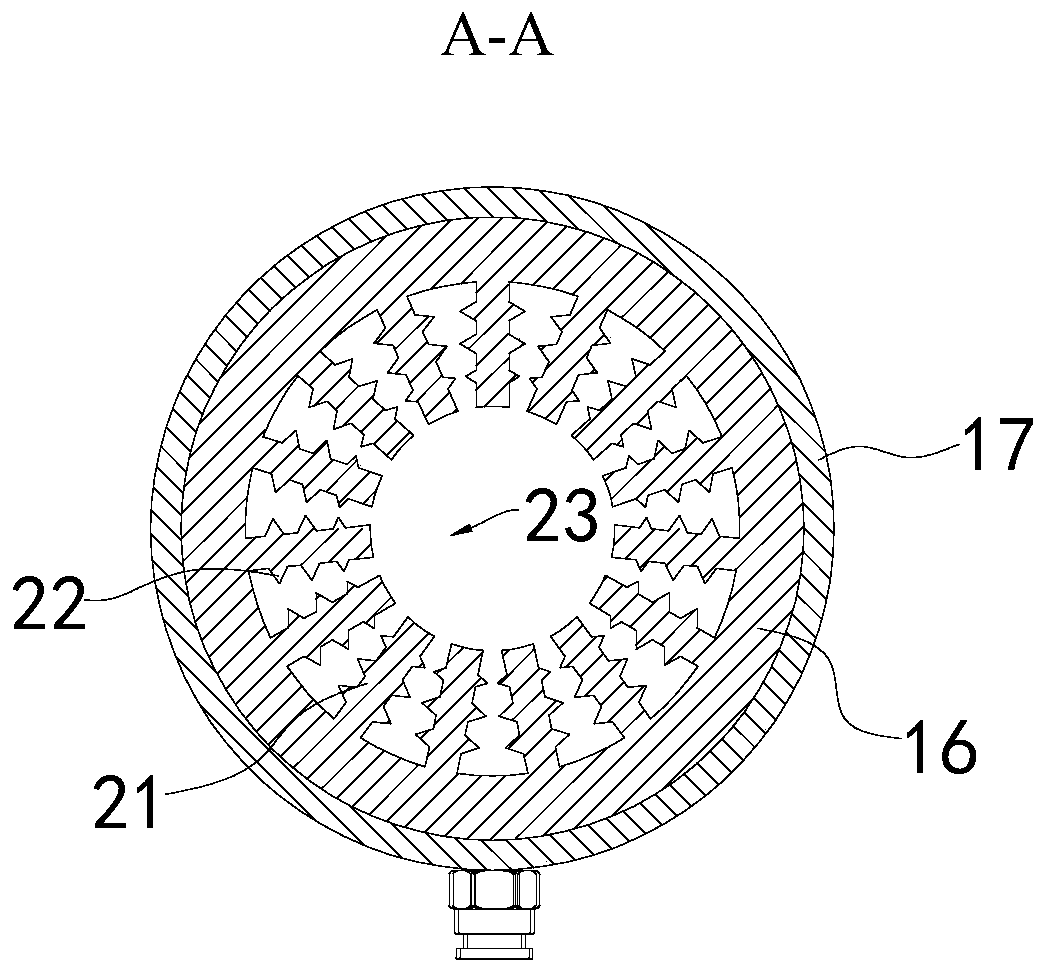

Centrifugal compressor and hydrogen fuel cell system

ActiveCN110594170AReduce output torqueReduced Power RequirementsReactant parameters controlPump componentsHydrogen fuel cellHydrogen fuel

The invention discloses a centrifugal compressor and a hydrogen fuel cell system. The centrifugal compressor comprises a machine shell, a rotating shaft, an impeller, a motor assembly, a first volute,a turbine, a second volute and a heat exchanger, wherein the machine shell is equipped with a first cooling medium flow path; the rotating shaft penetrates through the machine shell; the impeller isconnected with one end of the rotating shaft; the motor assembly comprises a rotor and a stator; the rotor is connected with the rotating shaft; the stator is arranged on the outer side of the rotor and connected with the machine shell; the first volute is connected with the machine shell and covers the outer side of the impeller; a first air inlet and a first air outlet are arranged on the firstvolute; the turbine is connected with the other end of the rotating shaft; the second volute is connected with the machine shell and covers the outer side of the turbine; a second air inlet and a second air outlet are arranged on the second volute; a second cooling medium flow path is arranged inside the heat exchanger and communicates with the first cooling medium flow path; the heat exchanger isequipped with a penetrating airflow channel; and the airflow channel communicates with the second air outlet. The hydrogen fuel cell system comprises an electric pile and the centrifugal compressor.By the adoption of the technical scheme, the energy utilization rate can be higher and the service life can be prolonged.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

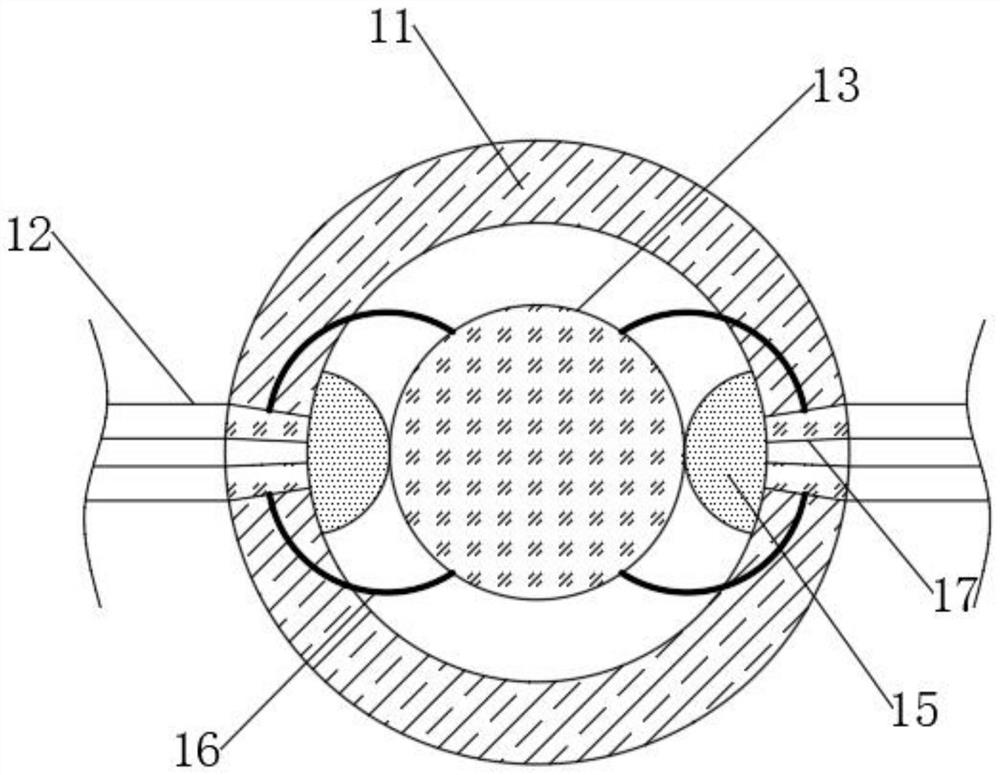

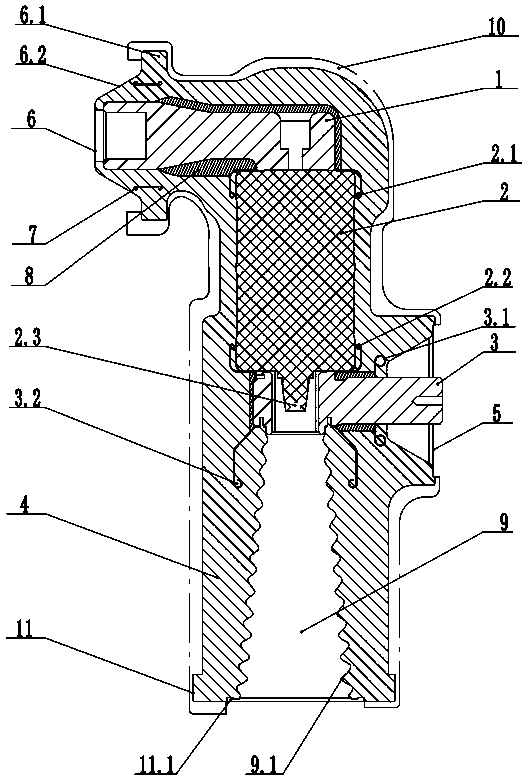

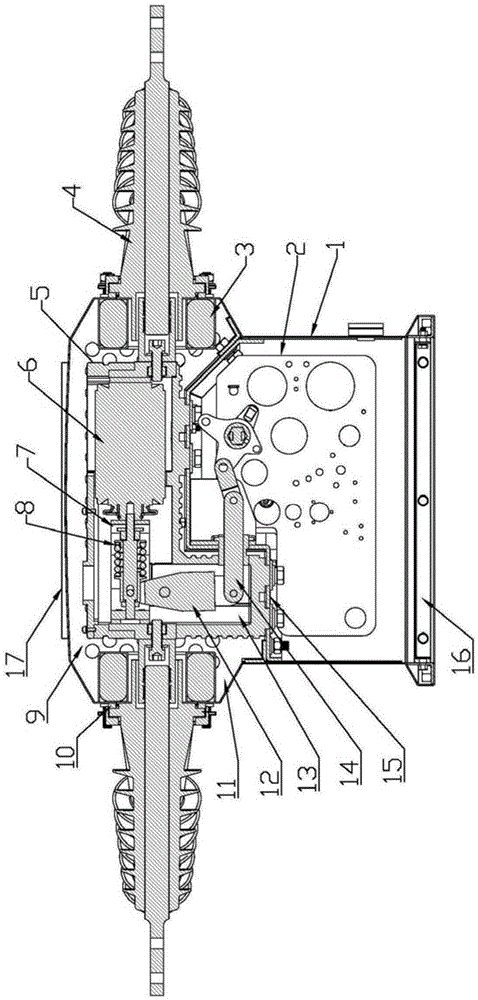

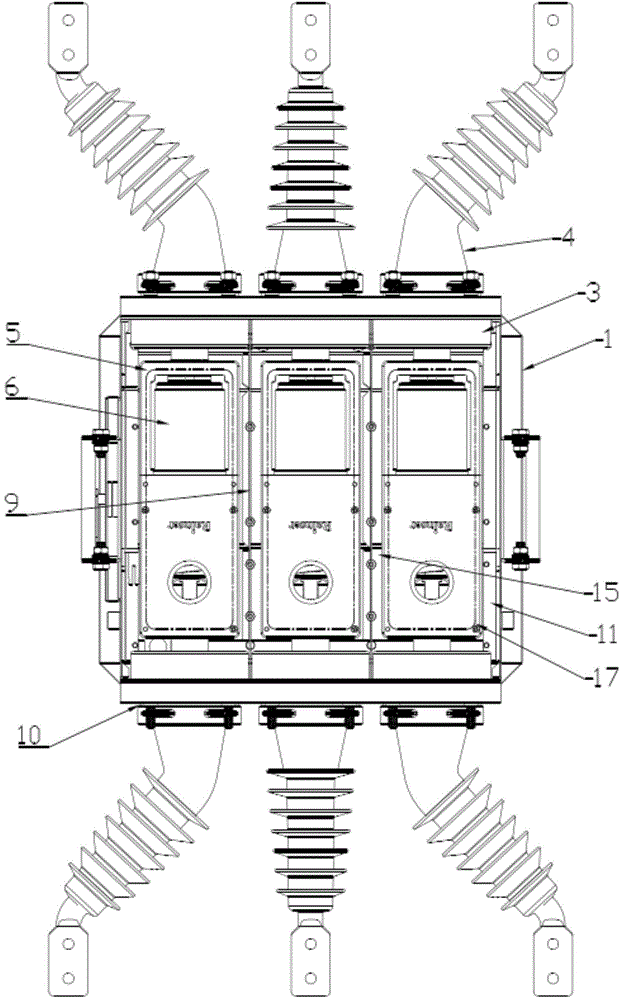

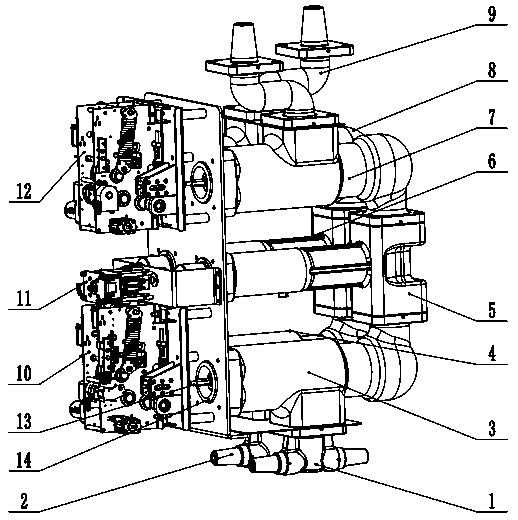

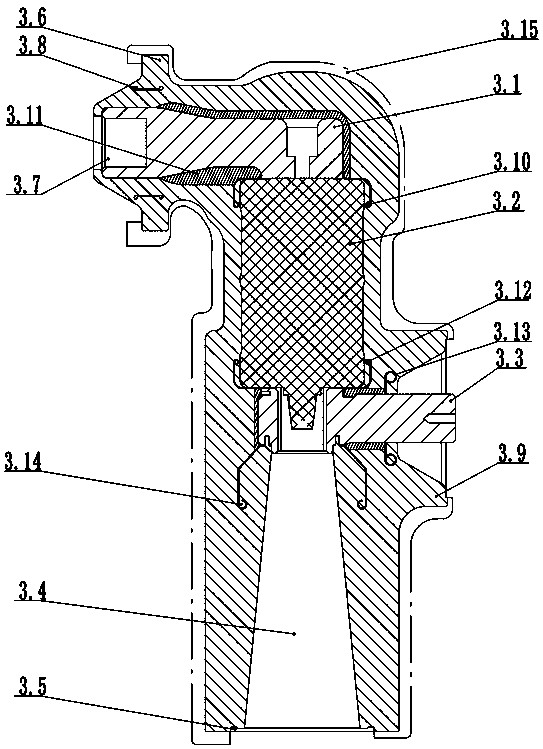

Circuit breaker pole for railway traction lines

ActiveCN109841449AReduce volumeImprove dustproofHigh-tension/heavy-dress switchesAir-break switchesEngineeringCopper

The invention relates to the field of high-voltage electrical equipment, in particular to a circuit breaker pole for railway traction lines. The circuit breaker pole includes a static end copper conductive part, a vacuum arc extinguishing chamber, a moving end copper conductive part, a tie rod chamber, a semi-conductive buffer layer and a semi-conductive shielding layer. The semi-conductive bufferlayer is arranged between a conductive body and the sealed part of a solid insulating material. The semi-conductive shielding layer is solidified at the non-connection part on the surface of a solidinsulating material, and the semi-conductive shielding layer is connected with a shell. A bottom flange of the circuit breaker pole is provided with a corrugated sleeve groove. Voltage equalizing parts are arranged at the joints of the conductive body to eliminate the phenomenon of partial point discharge. The size of switches is reduced. The partial discharge quantity of products is reduced, theservice life of products is prolonged, and the reliability is improved.

Owner:GUANGXI YINHE DECOM ELECTRIC

Prestressed thermal insulation oil casing and production method thereof

ActiveCN103850654AImprove insulation performanceSlow down the phenomenon of "hydrogen permeation"Drilling rodsDrilling casingsThermal insulationEngineering

The invention relates to a prestressed thermal insulation oil casing. The prestressed thermal insulation oil casing is characterized by comprising an outer tube, a middle tube and an inner tube which are sleeved at intervals, wherein an internal thread is processed on one end of the middle tube, an external thread is processed on the other end of the middle tube, one end, which is provided with the internal thread, of the middle tube is welded with the outer tube at a tube end, and is welded with the inner tube at a reserved internal thread length position, one end, which is provided with the external thread, of the middle tube is welded with the outer tube at a reserved external thread length position, and is welded with the inner tube at a tube end; an annulus, which is formed by the outer tube and the middle tube, is filled with a thermal insulation material, and is vacuumized so as to form a first thermal insulation layer, after an annulus, which is formed by the middle tube and the inner tube, is vacuumized, inert gas is filled so as to form a second thermal insulation layer; the prestressed thermal insulation oil casing comprises the following production steps of pretreating three tubes, sleeving and welding the inner tube and the middle tube, treating the annulus of the inner tube and the middle tube, sleeving and welding the outer tube and the middle tube, treating the annulus of the outer tube and the middle tube, testing a visible heat conductivity coefficient and processing screw threads on two ends of the middle tube in sequence. The prestressed thermal insulation oil casing is provided with three layers of steel pipes and two layers of thermal insulation structures, so that the prestressed thermal insulation oil casing has good thermal insulation performance and excellent working performance.

Owner:淄博孚瑞特热能科技有限公司

Semiconductor integrated circuit device including a fin-type field effect transistor and method of manufacturing the same

InactiveUS8445951B2Improve insulation lifeProlong lifeTransistorSolid-state devicesElectrical conductorEngineering

A semiconductor integrated circuit device, includes a first electrode including a first semiconductor layer formed on a substrate, a side surface insulating film formed on at least a part of a side surface of the first electrode, an upper surface insulating film formed on the first electrode and the side surface insulating film, a second electrode which covers the side surface insulating film and the upper surface insulating film, and a fin-type field effect transistor. The first electrode, the side surface insulating film, and the second electrode constitute a capacitor element. A thickness of the upper surface insulating film between the first electrode and the second electrode is larger than a thickness of the side surface insulating film between the first electrode and the second electrode, and the fin-type field effect transistor includes a second semiconductor layer which protrudes with respect to the plane of the substrate.

Owner:RENESAS ELECTRONICS CORP

All-solid insulating vacuum circuit breaker

ActiveCN104599897AExcellent adhesionImprove insulation lifeHigh-tension/heavy-dress switchesAir-break switchesEpoxyCoupling

The invention discloses a metal-enclosed all-solid insulating vacuum circuit breaker and particularly relates to an outdoor all-solid insulating pole-mounted vacuum switch. The all-solid insulating vacuum circuit breaker refers to that a fixed installing portion of a primary electrified body is formed by fixedly sealing purpose-made normal-temperature curing silicone rubber high in insulation performance in a metal box by means of integral one-time vacuum pouring; a movement portion of the primary electrified body comprises three-phase vacuum arc-extinguishing chamber moving contact terminals, flexible couplings, dynamic insulating pull rods and output insulating shafts and is formed by sealing another purpose-made normal-temperature curing silicone rubber high in insulation performance in cavities of epoxy resin insulating supporting frameworks by means of split-phase vacuum pouring. The all-solid insulating vacuum circuit breaker has the advantages that the primary electrified body of the circuit breaker is in all-solid seal and all-solid insulation integrally; metal partitions and silicon rubber are added among three phases for insulation, so that the three phases only have voltage to earth, line-to-line insulating voltage strength is reduced, and the overall insulation service life of the circuit breaker is prolonged; the silicon rubber insulation materials are environment friendly and recyclable, and accordingly, the all-solid insulating vacuum circuit breaker creates a new situation for environment friendliness, recycling and reusing of circuit breaker equipment.

Owner:HEBEI RAINSER ELECTRIC EQUIP

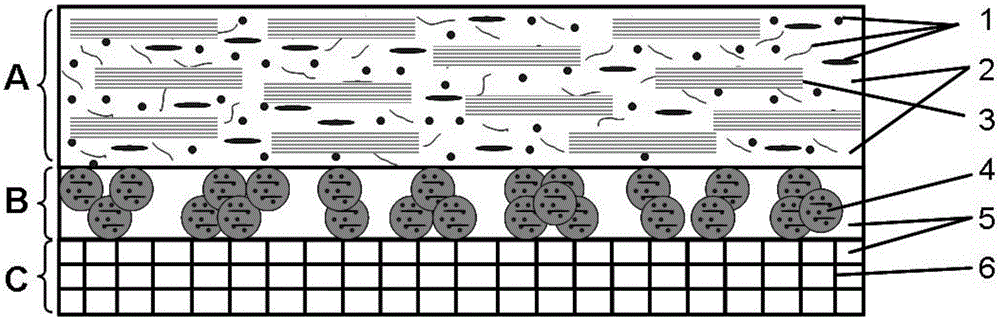

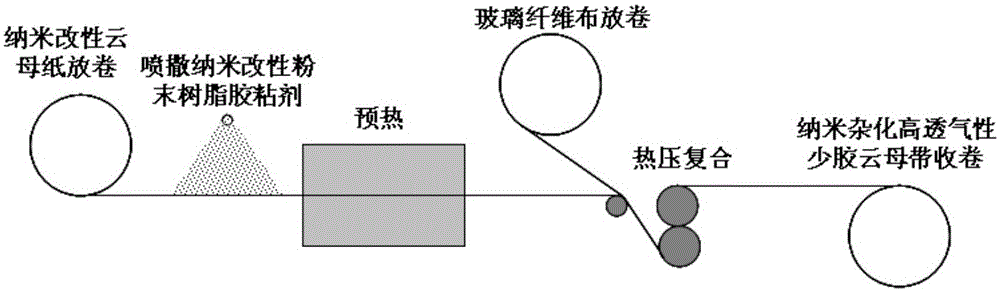

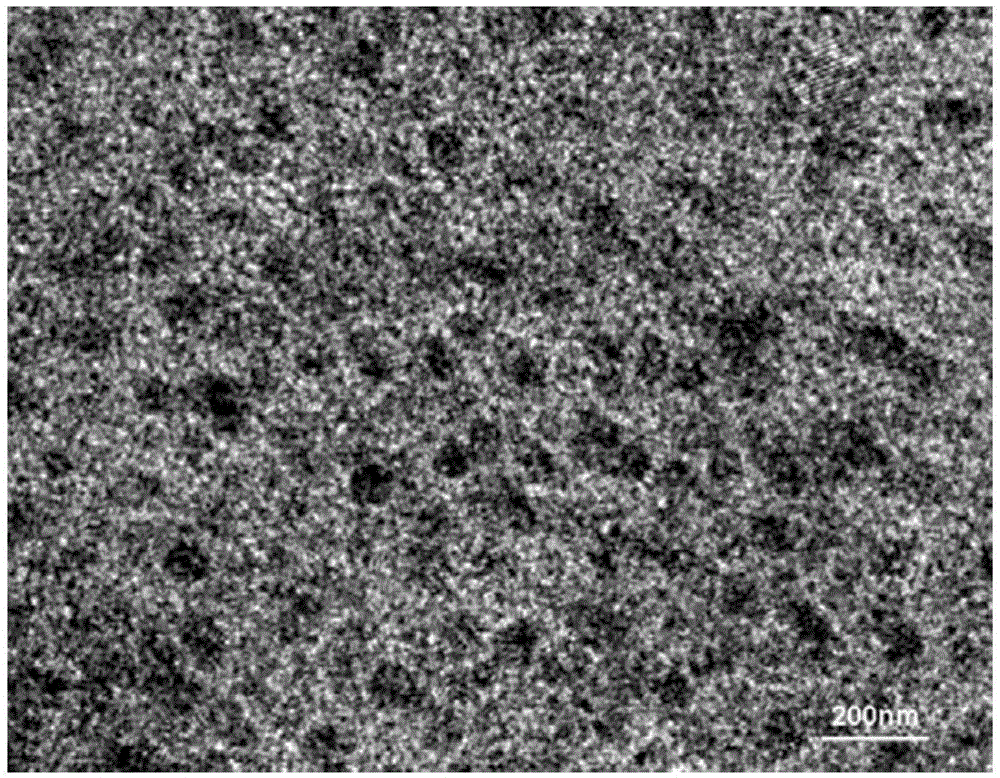

Corona-resistant, high-frequency pulse-resistant, high-permeability, low-glue mica tape suitable for variable-frequency high-voltage motors and preparation method thereof

ActiveCN103489543BImprove breathabilityImprove corona resistanceMicaNatural mineral layered productsMelting temperatureHigh voltage

The invention relates to corona-resistant and high-frequency-impulse-resistant high-breathability little-rein mica tape which comprises a mica paper layer, a reinforcing material layer and an adhesion agent layer. The adhesion agent layer is formed by powder adhesion agents which are distributed in a dotted mode, and a large number of pore channels exist among the powder adhesion agents which are distributed in the dotted mode. The mica paper layer is formed by nano-modified mica paper, and the content of nanometer materials in the nano-modified mica paper is 20-100g / m<2>. The powder adhesion agents are nano-modified powder resin adhesion agents with the particle size ranging from 60 to 150 meshes and the melting temperature ranging from 60 to 160 DEG C, the content of nanometer materials in the nano-modified powder resin adhesion agents is 20wt%-50wt%, and the content of nanometer materials in the adhesion agent layer is 4-20g / m<2>. The mica tape is high in breathability, excellent in corona resistance and high-frequency impulse resistance performance and capable of prolonging the insulation life of variable-frequency (high-voltage) motors.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

PVC (Polyvinyl chloride) protective corner technology for external corner in heat preservation construction of exterior wall

ActiveCN105715049AExtend insulation lifeAvoid damageHeat proofingBuilding material handlingGlass fiberPolyvinyl chloride

The invention provides a PVC (Polyvinyl chloride) protective corner technology for an external corner in heat insulation construction of an exterior wall. The technology comprises the following steps of laying a finished PVC protective corner with double-wing mesh cloth at each position of external corners, such as large external corners, windows, cornices and holes, of a wall surface before surface mortar is plastered on the exterior wall for heat insulation for the last time; arranging a through line at each external corner position; firstly plastering rendering putty on the bottom layer, adjusting the protective corner installation position according to the through line, pressing the double-wing mesh cloth, then plastering wall surface putty and pressing glass fiber mesh cloth, and plastering the surface mortar for the last time. The PVC protective corner technology for the external corner in the heat insulation construction of the exterior wall has the advantages that the heat insulation quality and acceptance check of the exterior wall conform to standard error requirements, the sealing property and safety of the exterior heat insulation system of the exterior wall are improved, and the durability of the exterior heat insulation system of the exterior wall is guaranteed; meanwhile by utilization of the protective corner, the construction speed is increased, the construction period can be shortened, the labor cost is reduced, the construction cost is reduced, the impact resistance of the external corner is improved, a wall corner is effectively prevented from being damaged, the appearance quality is improved, the construction quality is improved, and the service life of the exterior wall for heat insulation is prolonged.

Owner:天津市既有建筑修缮技术服务中心

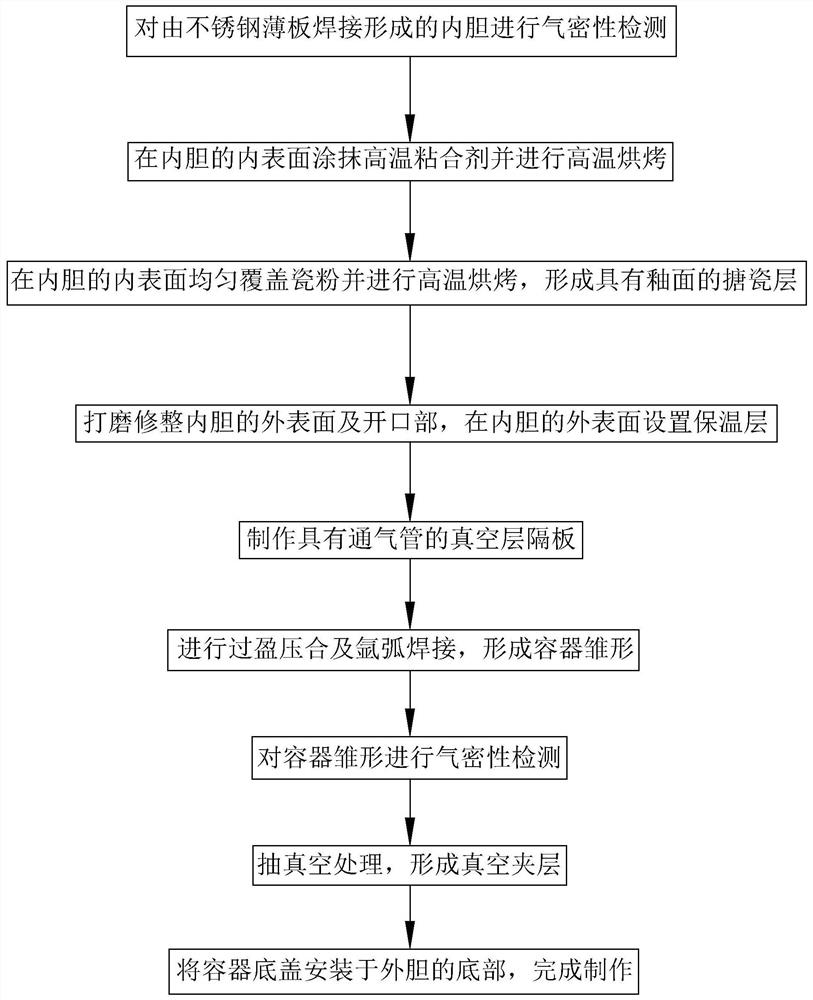

Manufacturing process of enamel heat preservation container

ActiveCN108421684BImprove insulation effectPrevent precipitationPretreated surfacesCoatingsSS - Stainless steelMaterials science

The invention discloses a manufacturing process of an enamel heat preservation container. An enamel layer is made on the inner surface of the inner container, and the surface of the enamel layer evenly covers the inner surface of the inner container to form a glazed surface. Therefore, the enamel layer can cover the inner surface of the inner container The welding seam is completely covered, so as to avoid the direct exposure of the welding seam; in addition, the enamel layer can isolate the irritating liquid from the stainless steel material in the inner tank, thereby preventing the irritating liquid from corroding the stainless steel material, thereby avoiding irritation The corrosive liquid makes the stainless steel material precipitate metal components; in addition, the enamel layer can also effectively prevent the heat radiation loss of the liquid inside the enamel heat preservation container, thus playing a good heat preservation effect.

Owner:周雪松

A kind of external wall thermal insulation construction outside corner pvc corner protection technology

ActiveCN105715049BImprove insulation lifeAvoid damageHeat proofingBuilding material handlingGlass fiberPolyvinyl chloride

Owner:天津市既有建筑修缮技术服务中心

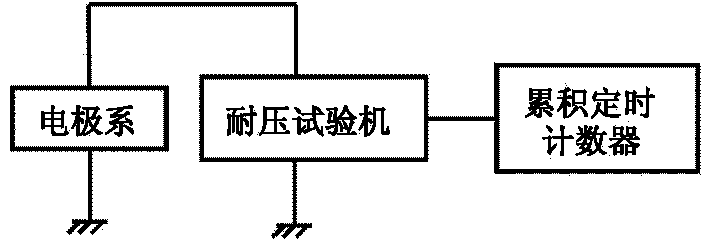

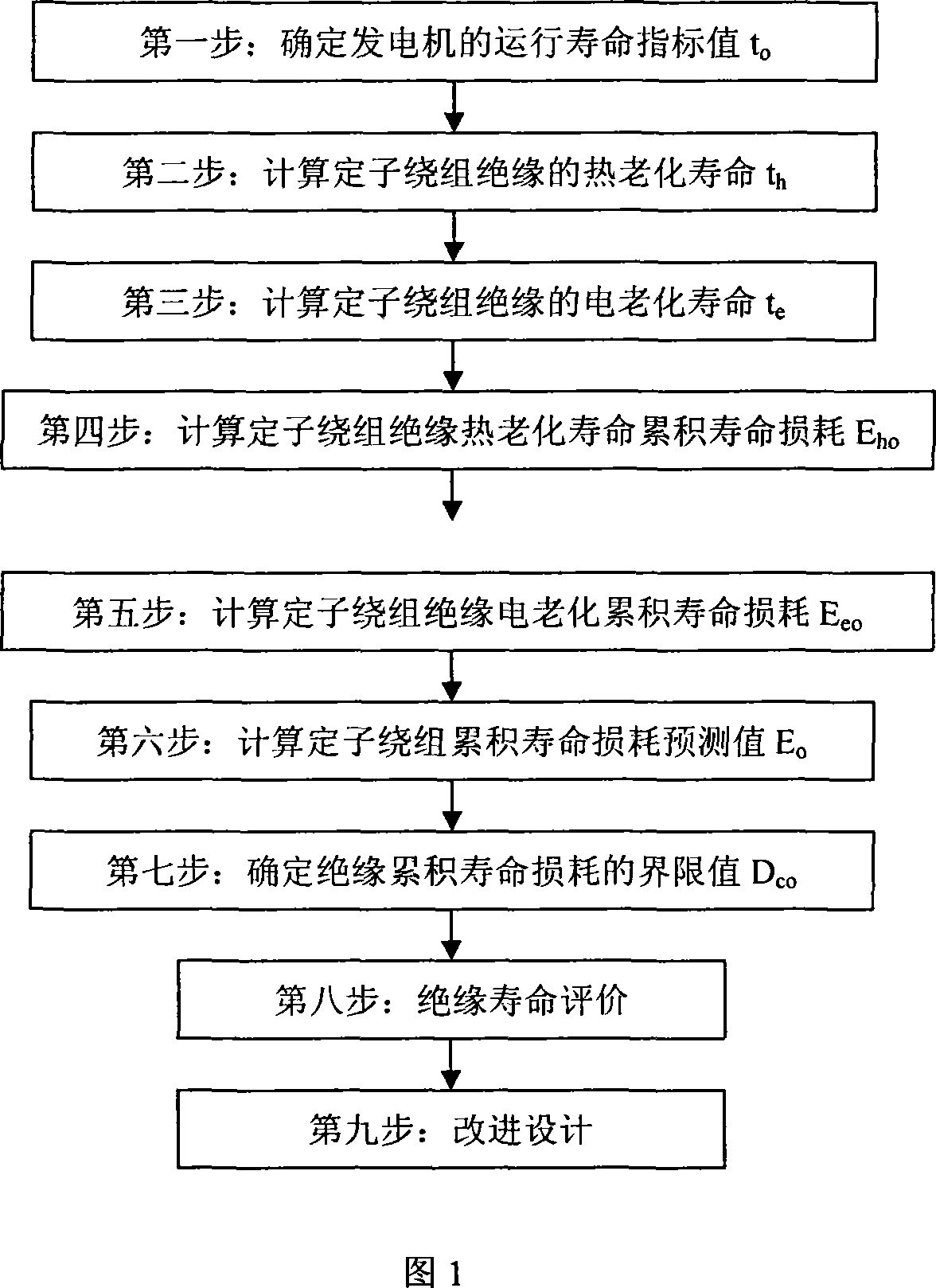

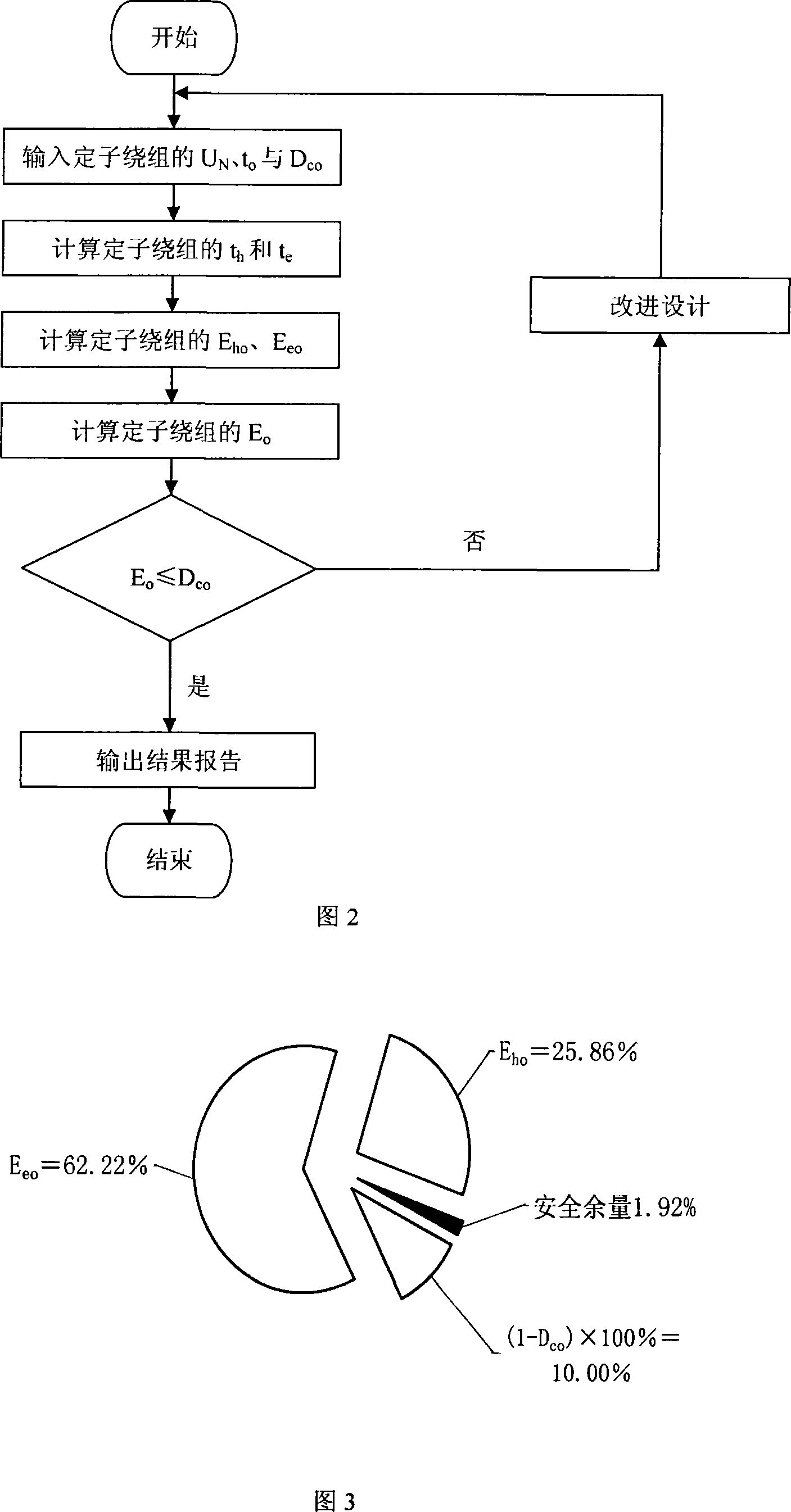

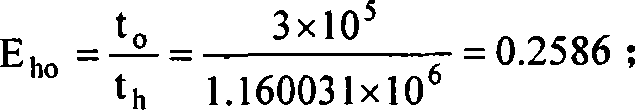

Design method for insulation service life of turbine generator stator winding and its appraising method

ActiveCN101132140ACumulative Life Loss ReductionProlonging the F-Class Insulation Life of Generator Stator WindingsData processing applicationsManufacturing dynamo-electric machinesStatorElectric generator

This invention relates to the method for the design and evaluation of a steam turbogenerator stator winding insulation life (SWIL). The characteristics are: the soft-ware for the design of F-grade SWIL programmed by C-language is installed in a computer of the design and research department of a steam turbogenerator producer. The evaluation procedures are: determining the desired value of the generator service life, calculating the thermal aging SWIL, calculating the electric aging SWIL, calculating the accumulated loss of the thermal aging SWIL, determining the boundary value Dco the said accumulated loss, and finally proceeding this inventive design and evaluation. The advantages are: quantitative forecasting, quantitative evaluation and improvement of F-grade SWIL, meeting the technical requirement of 40 years life.

Owner:SHANGHAI POWER EQUIP RES INST

Vacuum composite heat-insulating pipeline connecting structure

InactiveCN101705795APrevent leakageImprove insulation performanceDrilling rodsDrilling casingsCouplingEngineering

The invention discloses a vacuum composite heat-insulating pipeline connecting structure, which comprises vacuum composite heat-insulating pipes, a coupler and a gland bush, wherein the coupler is a tubular structure; the two ends of an inner hole of the coupler are provided with threaded tapered holes respectively of which outer ends are greater while inner ends are smaller and which are connected with connecting parts of the two adjacent vacuum composite heat-insulating pipes respectively; the outer surface of the connecting part of the vacuum composite heat-insulating pipe is a threaded tapered surface matched with the threaded tapered hole at any end of the inner hole of the coupler; the end face of the vacuum composite heat-insulating pipe is provided with at least one circle of groove along a circumferential direction; and the gland bush is arranged in the groove between the end faces of the two vacuum composite heat-insulating pipes. The vacuum composite heat-insulating pipeline connecting structure can greatly improve heat-insulating property at junctions of the pipeline, prolong the heat-insulating service life of the pipeline, reduce the number of pipeline connecting parts and simplify the assembly process of the pipeline connecting parts, and is especially applied to the coupling of underground oil pipes for steam injection and oil extraction.

Owner:湖北贵族真空科技股份有限公司

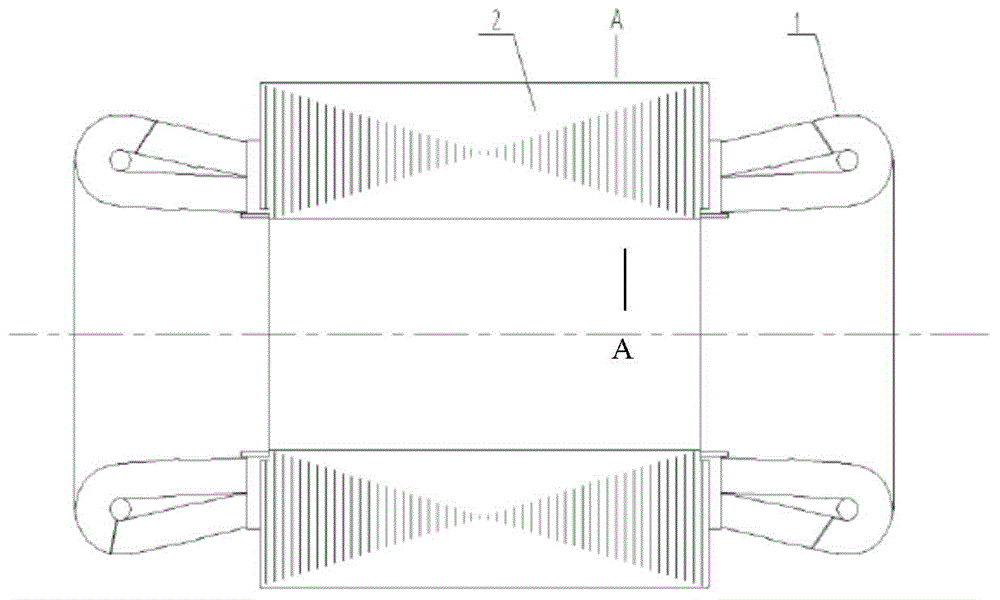

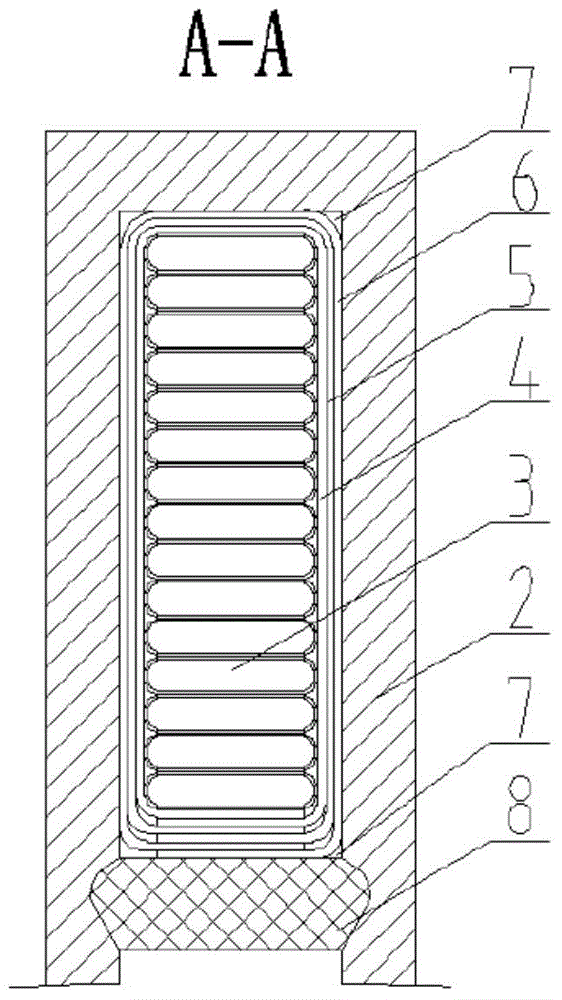

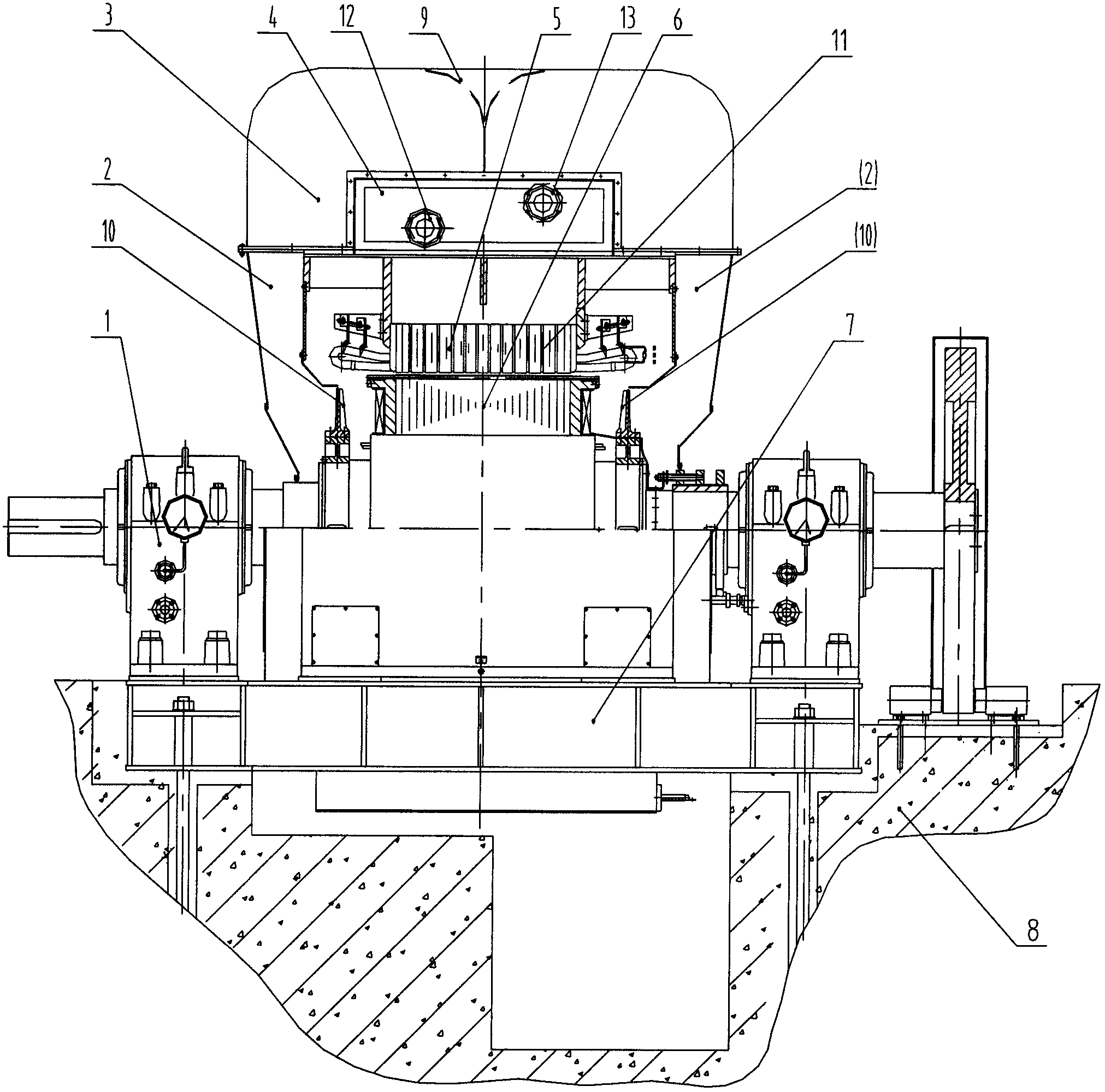

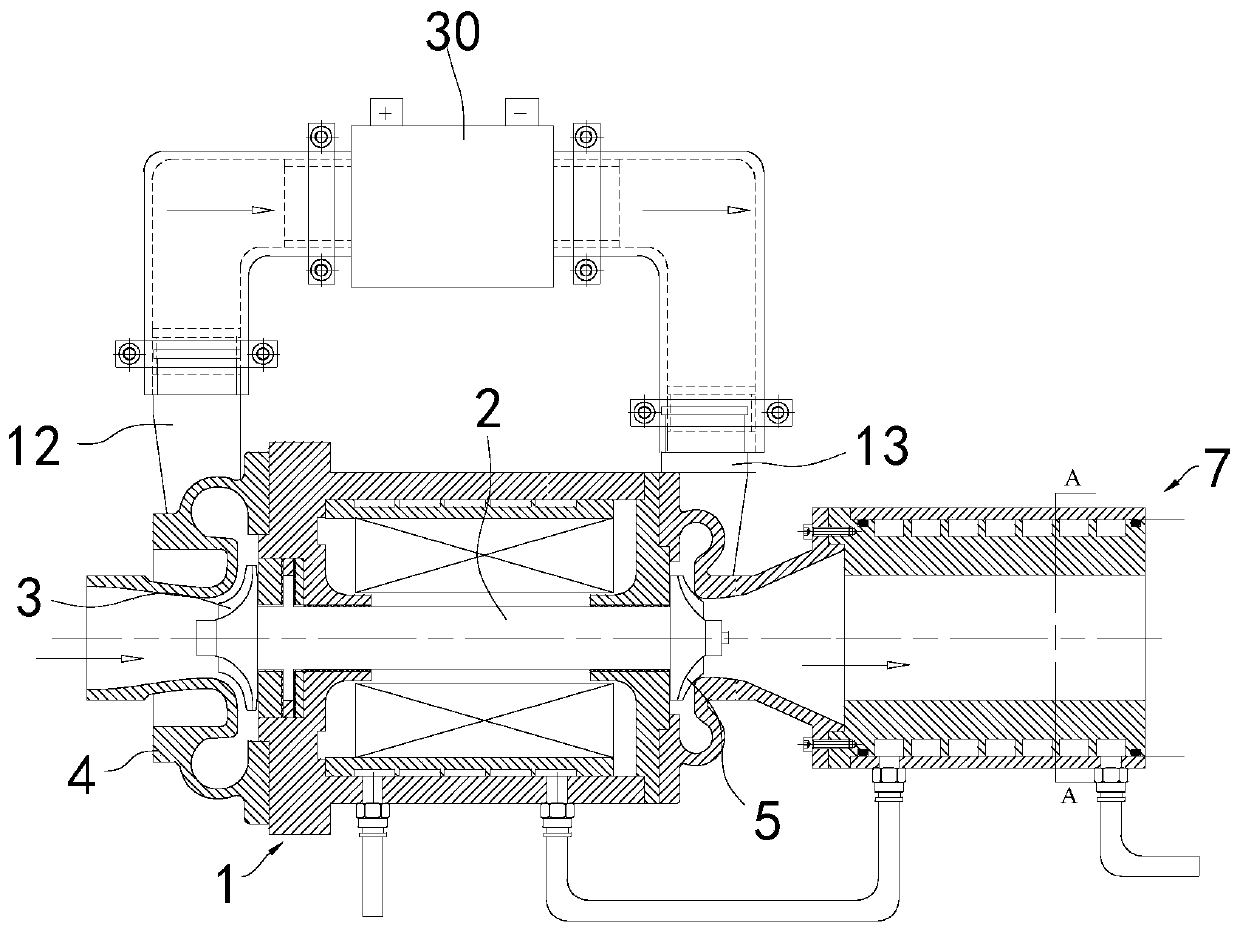

A bulb tubular hydroelectric generator

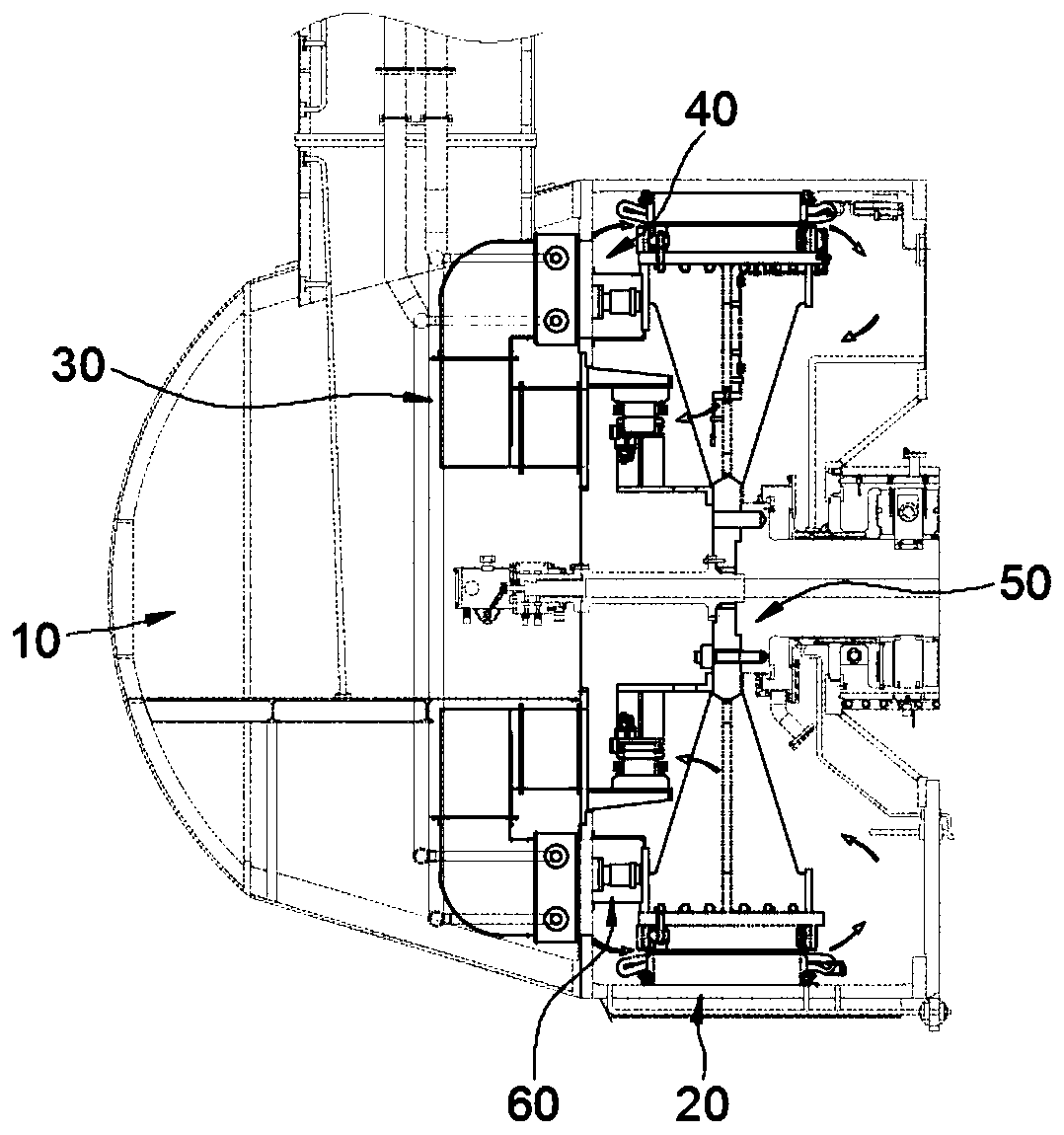

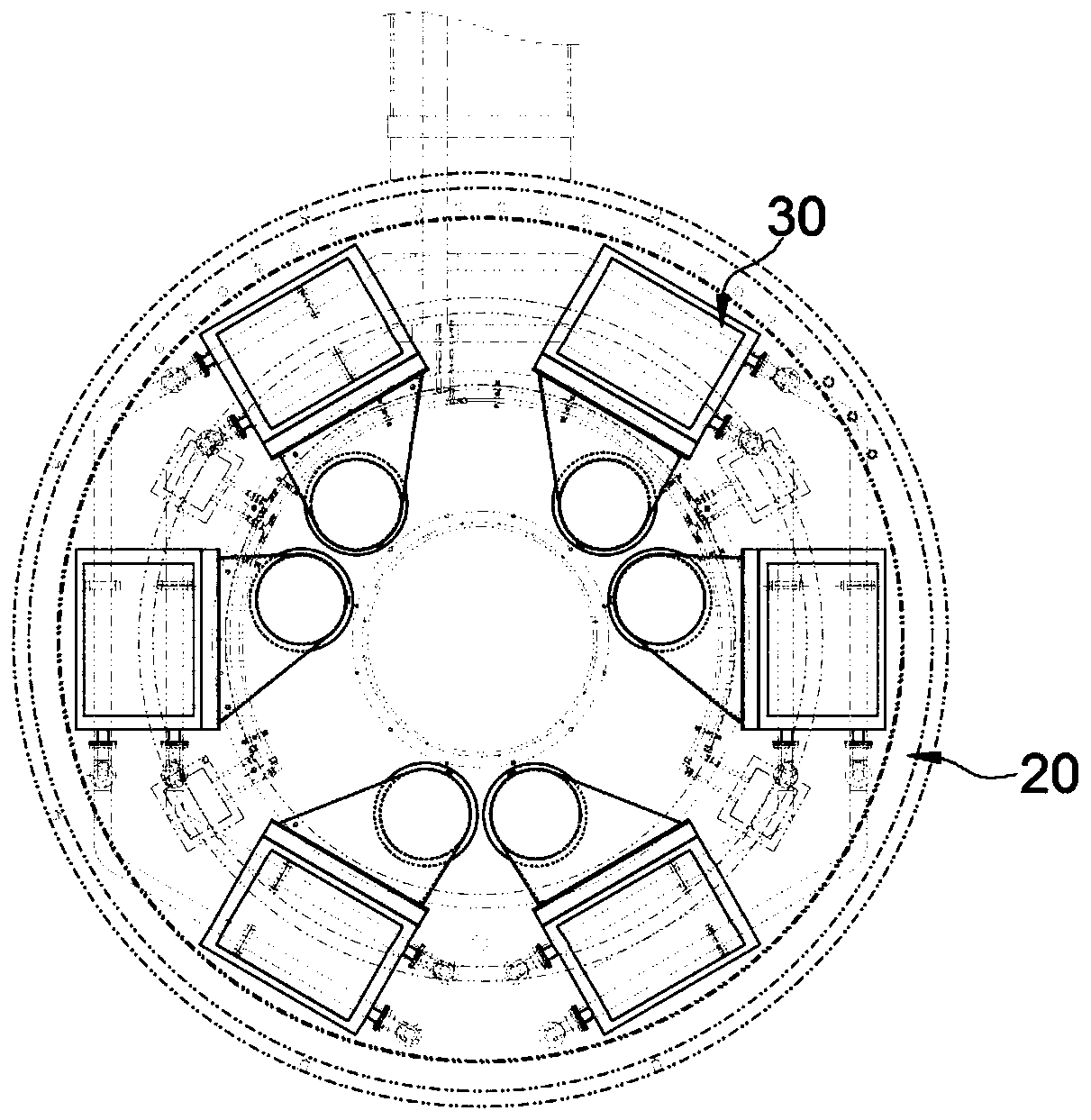

ActiveCN107147245BImprove insulation lifeImprove power qualityCooling/ventillation arrangementWater turbineFrequency generation

The invention provides a bulb tubular hydraulic generator, and belongs to the technical field of hydroelectric power generation equipment. The bulb tubular hydraulic generator comprises a bulb head and a stator frame integrally fixed and arranged in a co-movable manner, a generator body fixed in the stator frame, a stator upstream flange clamped between the stator frame and the bulb had, at least a group of ventilation assembly, and at least one group of wind screen assembly, a plurality of ventilation assemblies are fixed on the stator upstream flange and uniformly distributed at intervals in a co-circumferential manner, the wind screen assemblies are detachably fixed in the stator frame, the wind screen assemblies and the stator upstream flange are constructed to form a single-circulation air supply unit in which the wind screen assemblies communicate with the ventilation assemblies and the wind screen assemblies and the ventilation assemblies are mutually independent, the generator body comprises excitation assemblies, and the excitation assemblies and the stator frame are arranged in a coaxial manner. According to the bulb tubular hydraulic generator, brushless double-frequency generation can be realized, brushless variable-frequency generation can also be realized, the energy consumption of the whole ventilation system is reduced, the axial air quantity distribution can be effectively improved, and the ventilation and heat radiation effects of a unit can be improved.

Owner:湖南云箭集团有限公司

Railway Traction Transformer High Voltage Switchgear

ActiveCN109888657BReduce volumeImprove dustproofSwitchgear arrangementsSubstation/switching arrangement boards/panels/desksTraction transformerSwitchgear

The invention relates to the field of high voltage electrical equipment, in particular to rail traction high voltage switchgear. The rail traction high voltage switchgear comprises a main incoming circuit breaker, a standby incoming circuit breaker, a main earthing switch, a standby earthing switch, a main bus circuit breaker, a standby bus circuit breaker, an incoming sleeve, a bus sleeve, an incoming circuit breaker operating mechanism, an earthing switch operating mechanism and a bus circuit breaker operating mechanism. The circuit breaker is composed of a vacuum arc-extinguishing chamber,a copper conductive part and a solid insulating material. A semi-conductive buffer layer is arranged between the conductive part and the enclosed part of the solid insulating material. A semi-conductive electrical shielding layer is cured at the non-connected part of the surface of the solid insulating material, and the non-connected part of the surface of the solid insulating material is connected with the shell. A uniform piece is arranged at the joint of the conductive piece to eliminate a partial point discharge phenomenon. According to the rail traction high voltage switchgear provided bythe invention, the volume of the switch is reduced, the partial discharge magnitude of the product is improved, and the reliability is improved.

Owner:GUANGXI YINHE DECOM ELECTRIC

A railway traction transformer high voltage grounding switch

ActiveCN109872914BReduce volumeImprove dustproofAir-break switch detailsInsulation layerStructural engineering

The invention relates to the field of the high-voltage electrical equipment, especially a railway traction variable-high voltage grounding switch. The railway traction variable-high voltage groundingswitch comprises a grounding switch polar pole, a mounting plate, an operating mechanism, a grounding copper part, a grounding cutter, a conductive copper part, a semi-conductive shielding layer, a semi-conductive buffer layer, and an insulation layer. The grounding switch polar pole and the operating mechanism are located at two sides of the mounting plate; the operating mechanism is matched withthread in the grounding cutter through a lead screw, thereby driving the grounding cutter to make linear motion; the semi-conductive buffer layer is arranged between a conductor and a solid-sealing part of the solid insulation material; the semi-conductive shielding layer is cured at a non-connecting part of the surface of the solid insulation material, and is connected with a shell. The partialdischarge magnitude of the product is lowered, the product life is improved, and the reliability is improved.

Owner:GUANGXI YINHE DECOM ELECTRIC

Railway traction variable-high voltage grounding switch

ActiveCN109872914AReduce volumeImprove dustproofAir-break switch detailsLinear motionInsulation layer

The invention relates to the field of the high-voltage electrical equipment, especially a railway traction variable-high voltage grounding switch. The railway traction variable-high voltage groundingswitch comprises a grounding switch polar pole, a mounting plate, an operating mechanism, a grounding copper part, a grounding cutter, a conductive copper part, a semi-conductive shielding layer, a semi-conductive buffer layer, and an insulation layer. The grounding switch polar pole and the operating mechanism are located at two sides of the mounting plate; the operating mechanism is matched withthread in the grounding cutter through a lead screw, thereby driving the grounding cutter to make linear motion; the semi-conductive buffer layer is arranged between a conductor and a solid-sealing part of the solid insulation material; the semi-conductive shielding layer is cured at a non-connecting part of the surface of the solid insulation material, and is connected with a shell. The partialdischarge magnitude of the product is lowered, the product life is improved, and the reliability is improved.

Owner:GUANGXI YINHE DECOM ELECTRIC

Preparation method of electromagnetic wire for variable-frequency traction motor and product

PendingCN113921196AImprove insulation lifeImprove insulation reliabilityApparatus for heat treatmentCopper conductorPoly ether ether ketone

The invention discloses a preparation method of an electromagnetic wire for a variable-frequency traction motor. The preparation method is characterized by comprising the following steps: 1, carrying out finish rolling processing on an oxygen-free copper rod to form a copper conductor with a rectangular cross section; 2, forming a corona-resistant polyimide film layer on the surface of the copper conductor to wrap the copper conductor; 3, coating the corona-resistant polyimide film layer with a polyether-ether-ketone resin layer; and 4, after cooling and blow-drying, carrying out taking up. According to the invention, the polyetheretherketone resin is uniformly coated on the surface of the corona-resistant polyimide film layer by utilizing the characteristics of good high-temperature fluidity and high thermal decomposition temperature of the polyetheretherketone resin to form a self-lubricating protective layer, so that the corona-resistant polyimide film layer is prevented from being directly extruded and worn in the coil forming process, the anti-extrusion and anti-friction performance of the electromagnetic wire insulation layer is improved, the insulation service life of the electromagnetic wire insulation layer is prolonged, the insulation reliability of the electromagnetic wire is enhanced, and then the turn-to-turn insulation reliability of the motor stator coil is improved. The invention further provides the electromagnetic wire for the variable-frequency traction motor.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

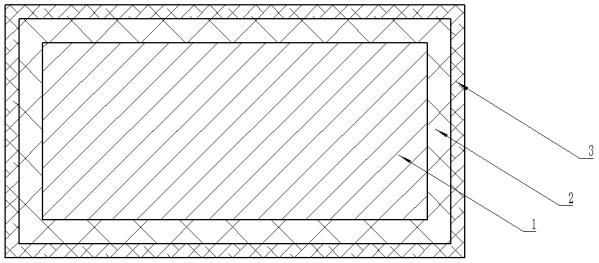

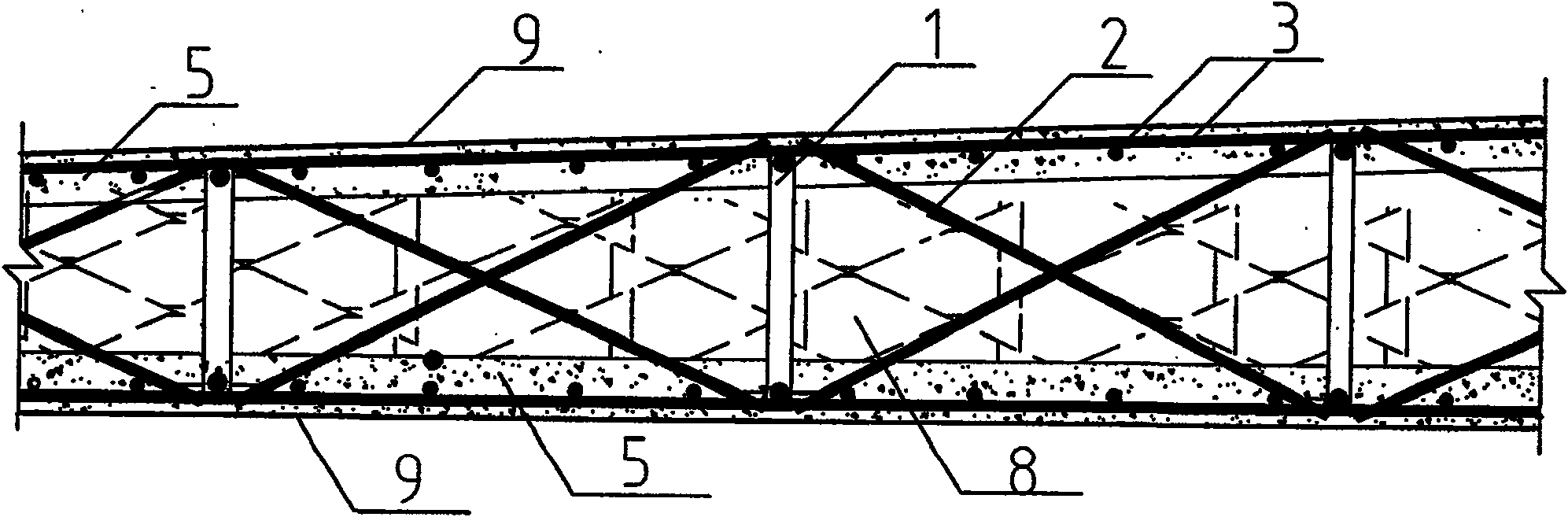

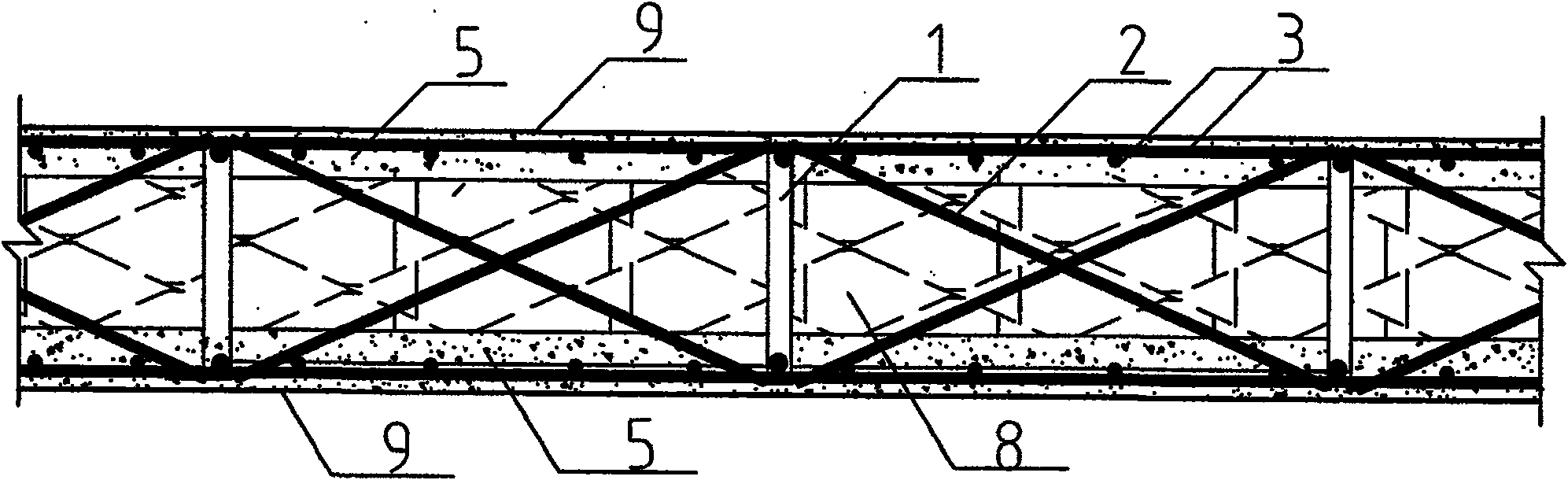

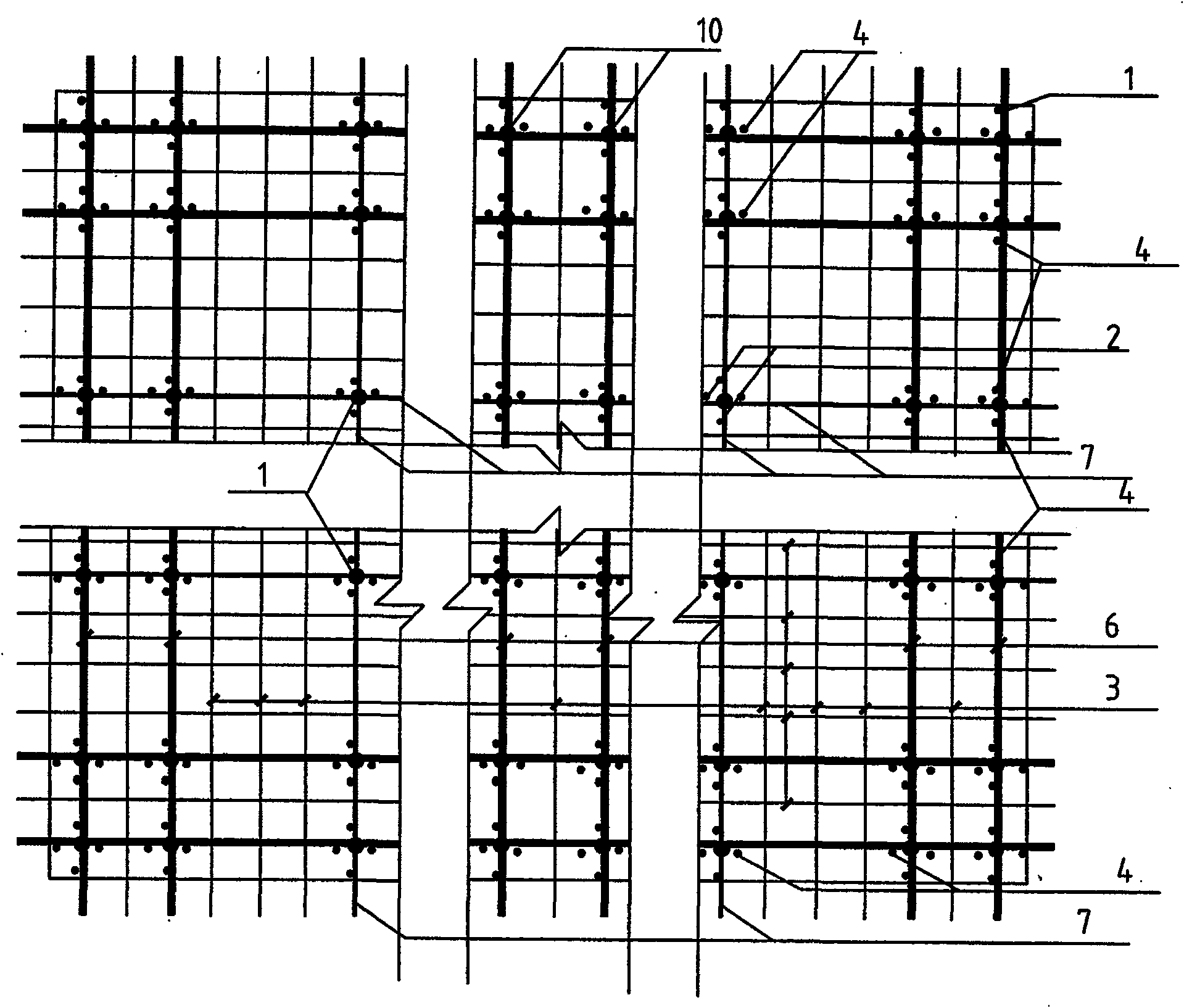

Insulation roof slab and method for making same

InactiveCN100567675CHigh tensile strengthEven by forceRoof covering using slabs/sheetsEarthquake resistanceGlass fiber

The invention relates to a panel for thermal insulation room, which is characterized in that the steel wire mesh frame is used as the skeleton frame; a plurality of concrete layers (5) are fixedly connected with both sides of the steel wire mesh frame; an empty cavity is formed between the concrete layers (5); the thermal insulation material is filled in the empty cavity to form the insulation layer (8); the thermal insulation material must be tightly closed to the internal walls of the concrete layer on both sides; an alkali resistant glass fiber mesh cloth (9) is embedded in the outer side of the concrete layer (5). The construction method comprises four steps: making the skeleton frame of the steel wire mesh frame, preparing the concrete material, making the concrete layer and forming the insulation layer. The panel for thermal insulation room has the advantages of earthquake resistance, light weight, high strength, impermeability, endurance, sound insulation, fire resistance, energy conservation, thermal insulation and higher efficiency of construction, and is more particularly suitable for construction engineering.

Owner:山东深科保温板墙开发股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com