A bulb tubular hydroelectric generator

A water turbine generator and light bulb cross-flow technology, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problem of affecting the service life of each component of the generator, the narrow internal space of the main generator, and the unfavorable heat dissipation of the generator and other problems, to achieve the effects of excellent power supply quality, improved axial air volume distribution, and good bottoming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

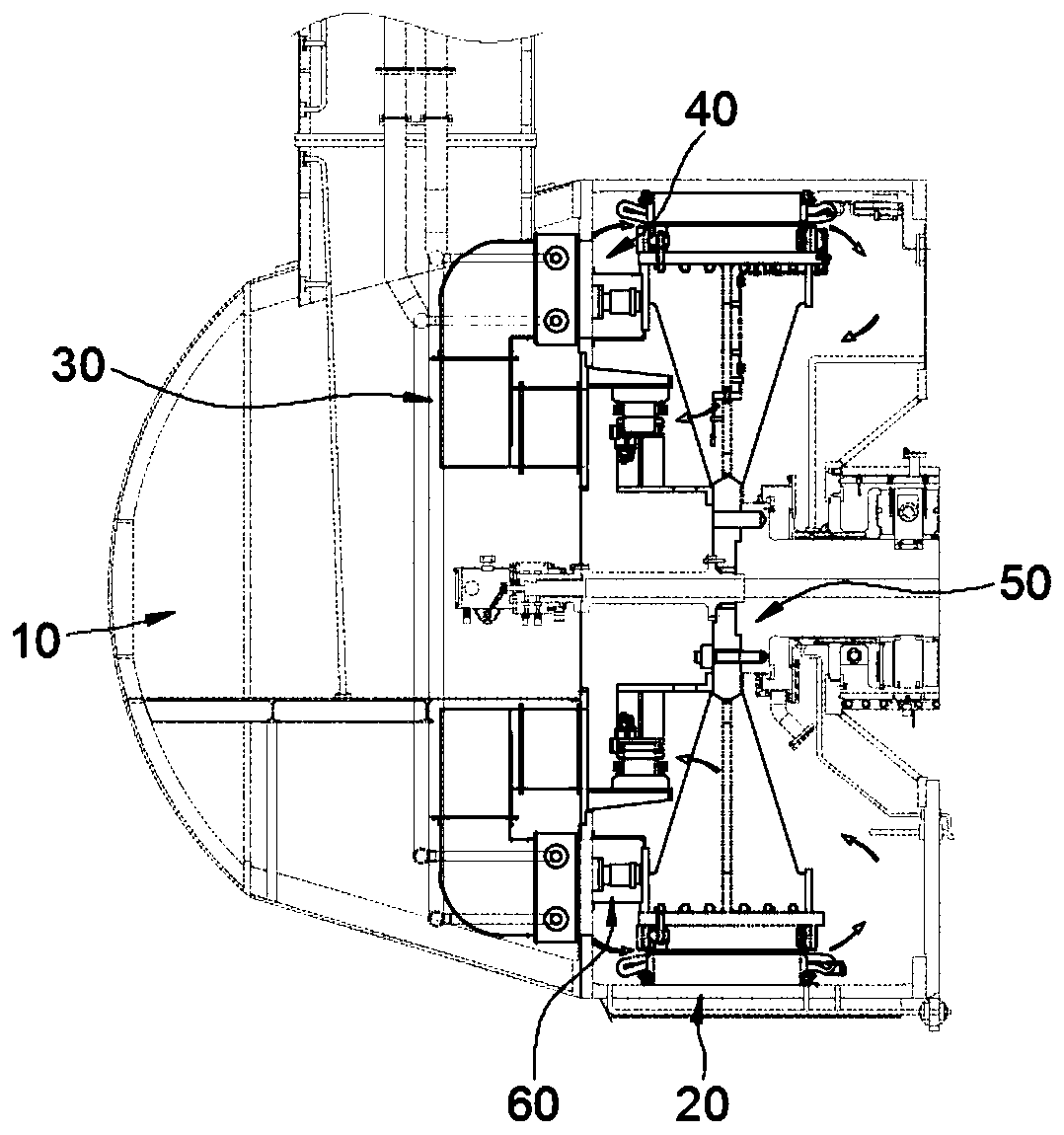

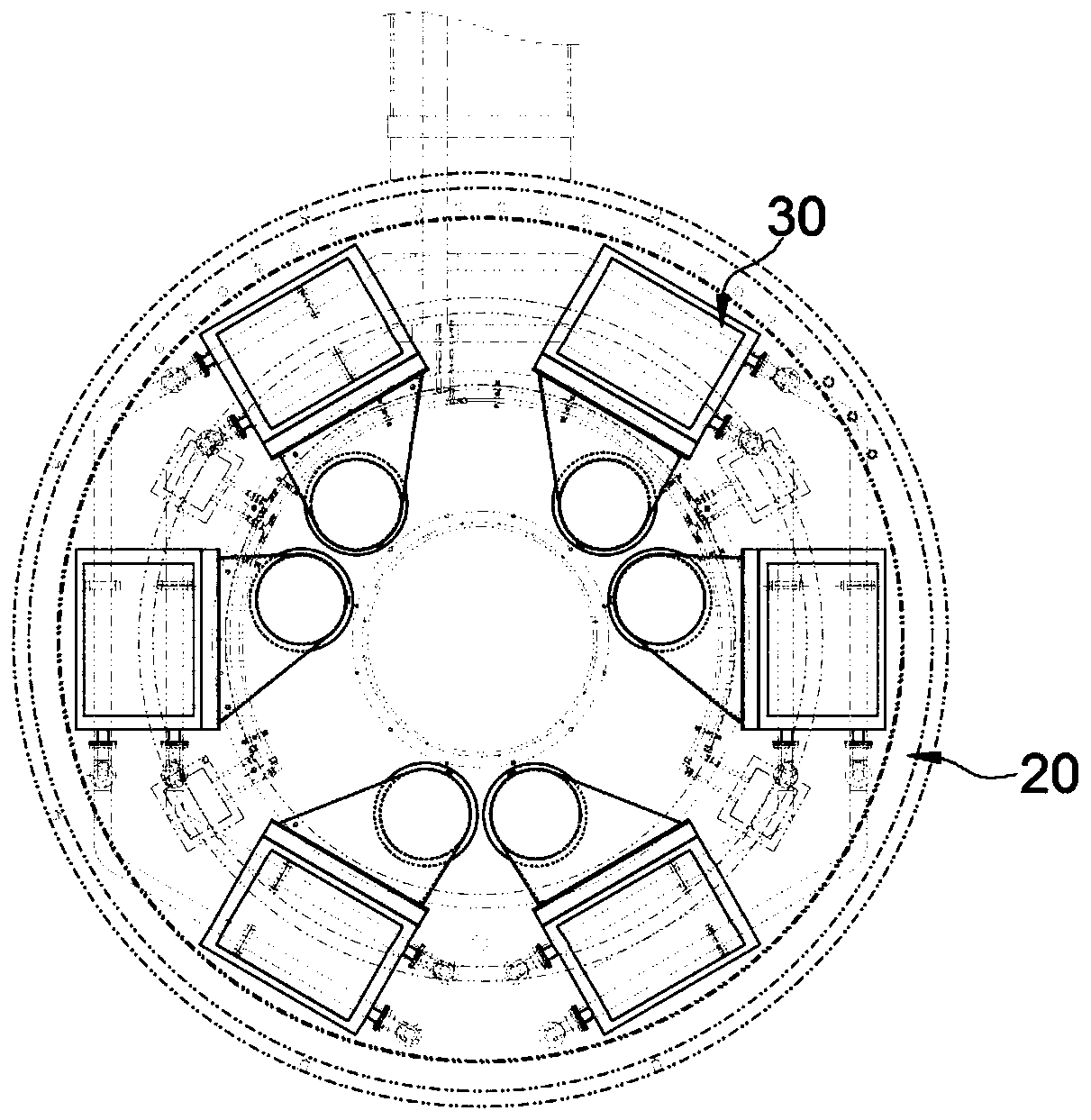

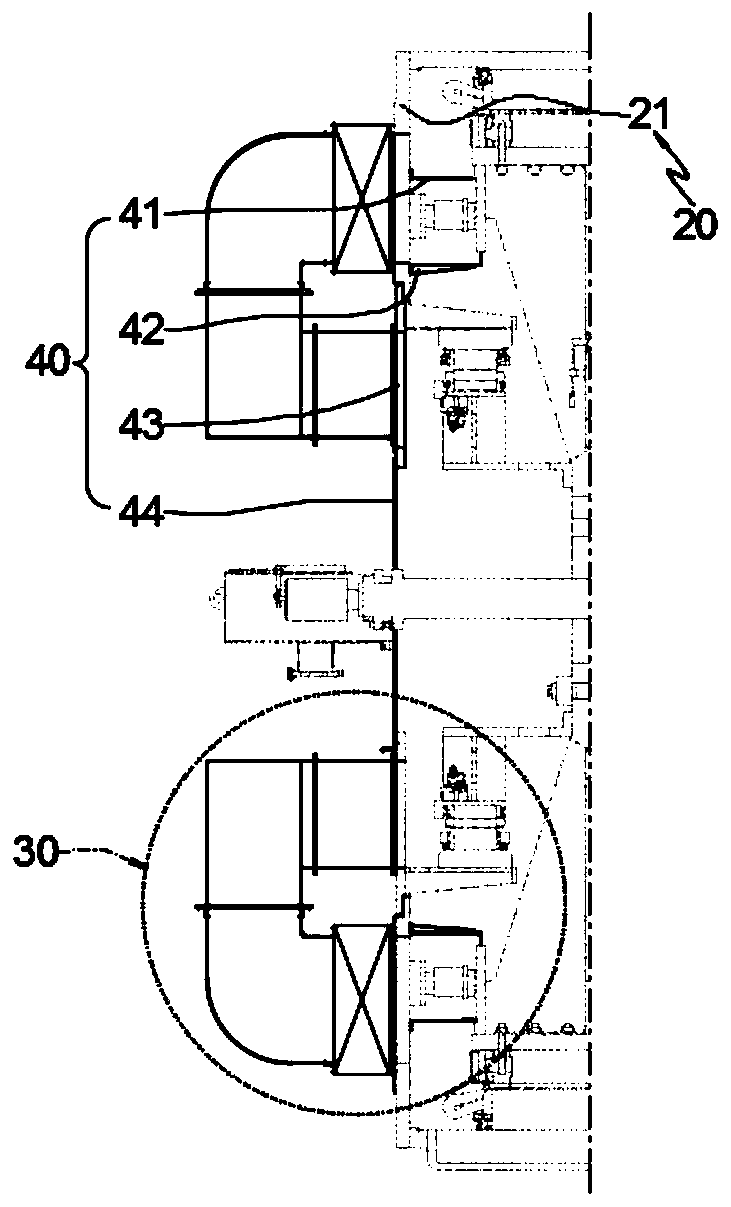

[0050] The present invention will be further described in detail and completely below in conjunction with the embodiments and the accompanying drawings.

[0051] For the convenience of description, spatially relative terms may be used here, such as "on ...", "over ...", "on the surface of ...", "above", etc., to describe the The spatial positional relationship between one device or feature shown and other devices or features. It will be understood that the spatially relative terms are intended to encompass different orientations of the device in use or operation in addition to the orientation depicted in the figures. For example, if the device in the figures is turned over, devices described as "above" or "above" other devices or configurations would then be oriented "beneath" or "above" the other devices or configurations. under other devices or configurations”. Thus, the exemplary term "above" can encompass both an orientation of "above" and "beneath". The device may be o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com