Railway traction variable-high voltage grounding switch

A high-voltage grounding switch and railway traction technology, which is applied to air switch parts and other directions, can solve the problems of large volume, difficult temperature rise control, and low safety of gas-insulated switches, so as to improve operation safety, dust and water vapor The ability to reduce the size of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

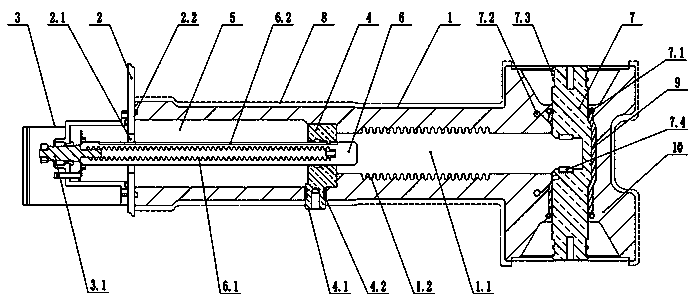

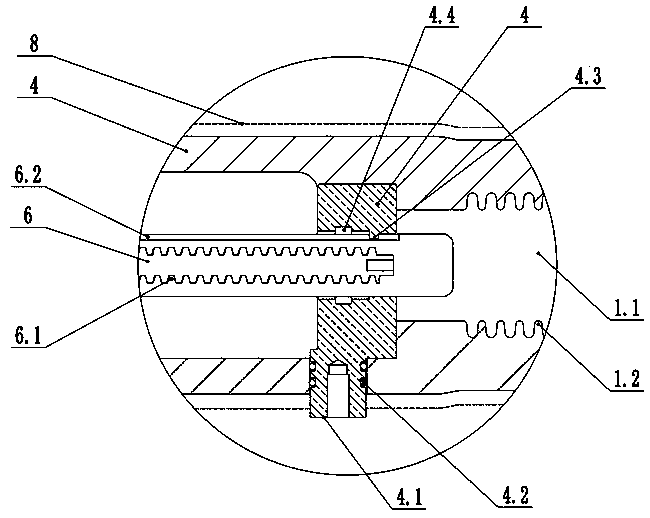

[0015] like figure 1 and figure 2 As shown, a high-voltage grounding switch for a railway traction transformer includes a grounding switch pole 1, a mounting plate 2, an operating mechanism 3, a grounding copper piece 4, a grounding knife 6, a conductive copper piece 7, a semiconductive shielding layer 8, a semiconductive Buffer layer 9, insulating layer 10. The grounding switch pole 1 and the operating mechanism 3 are located on both sides of the mounting plate 2. The operating mechanism 3 cooperates with the thread 6.1 in the grounding knife 6 through the screw rod 3.1 to drive the grounding knife to move linearly. The grounding knife 6 passes the grounding copper piece 4, and the grounding copper piece 4 has guide block 4.3, and the guide block 4.3 stretches in the guide groove 6.2, prevents the grounding knife from following the screw mandrel to rotate. The grounding copper piece 4 conducts with the grounding knife 6 through the grounding spring contact finger 4.4. The...

Embodiment 2

[0022] The connection end of the switch is an external cone interface with an external cone flange. A live sensor that can play a role in pressure equalization is arranged in the outer cone flange. The solid insulating material is epoxy resin. The pressure equalizer is made of 0.5 mm thick stainless steel mesh. All the other are with embodiment 1.

Embodiment 3

[0024] The solid insulating material is EPDM rubber. The pressure equalizing part is made of carbon fiber through mold processing. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com