Thermal insulation coating and preparation method thereof

A technology of thermal insulation coating and alcohol ester, applied in textiles, papermaking, fiber processing, etc., can solve the problems of unsatisfactory thermal insulation effect, complicated preparation method, shortened thermal insulation life, etc., and achieves good thermal insulation effect, simple equipment, The effect of long insulation life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

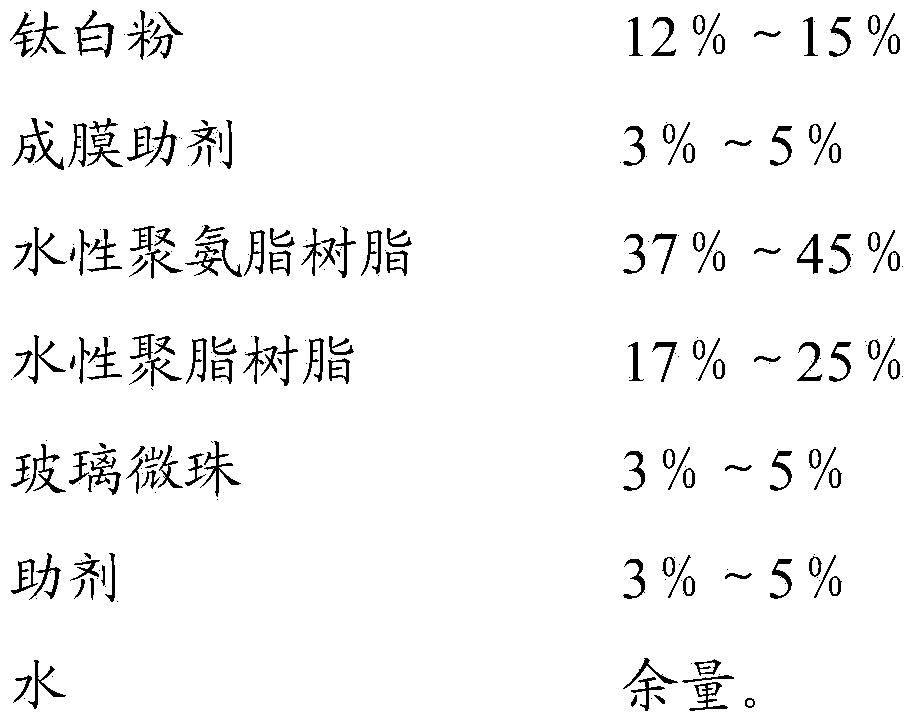

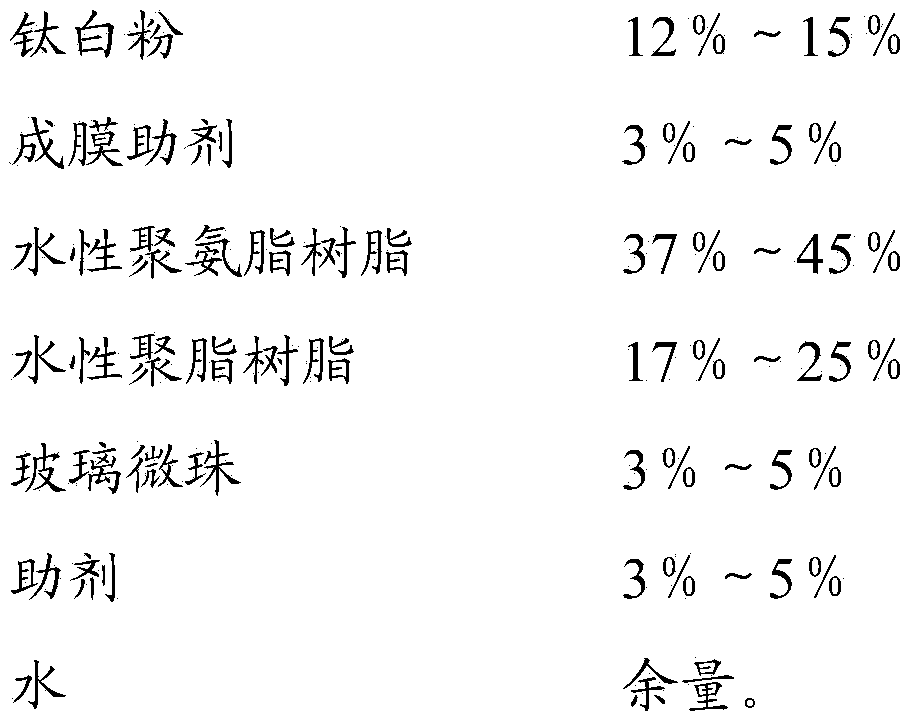

[0031] A heat-insulating paint, comprising 12% of titanium dioxide, 5% of film-forming aids, 45% of water-based polyurethane resin, 17% of water-based polyester resin, 13% of water, 3% of glass microspheres, and auxiliary agent 5%.

[0032] The method for preparing the heat-insulating coating specifically includes: mixing the amount of titanium dioxide, film-forming aids, water-based polyurethane resin, water-based polyester resin, water, glass microspheres and additives at 8°C, Put them into a reaction kettle with a stirring speed of 600 rpm according to the sequence, and stir evenly to obtain the heat-insulating coating.

Embodiment 2

[0034] A heat-insulating coating, comprising 15% of titanium dioxide, 3% of film-forming aids, 37% of water-based polyurethane resin, 25% of water-based polyester resin, 12% of water, 5% of glass beads, and agent 3%.

[0035] The method for preparing the heat-insulating coating is as follows: mix the amount of titanium dioxide, film-forming aids, water-based polyurethane resin, water-based polyester resin, water, glass microspheres and additives at 10°C, Put them into a reaction kettle with a stirring speed of 450 rpm in sequence, and stir evenly to obtain the heat-insulating coating.

Embodiment 3

[0037] A heat-insulating coating, comprising 13% of titanium dioxide, 4% of film-forming aids, 40% of water-based polyurethane resin, 20% of water-based polyester resin, 15% of water, 4% of glass microspheres, and auxiliary agent 4%.

[0038] The method for preparing the heat-insulating coating is specifically: put the amount of titanium dioxide, film-forming aids, water-based polyurethane resin, water-based polyester resin, water, glass microspheres and additives at 20°C, Put them into a reaction kettle with a stirring speed of 500 rpm in sequence, and stir evenly to obtain the heat-insulating coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com