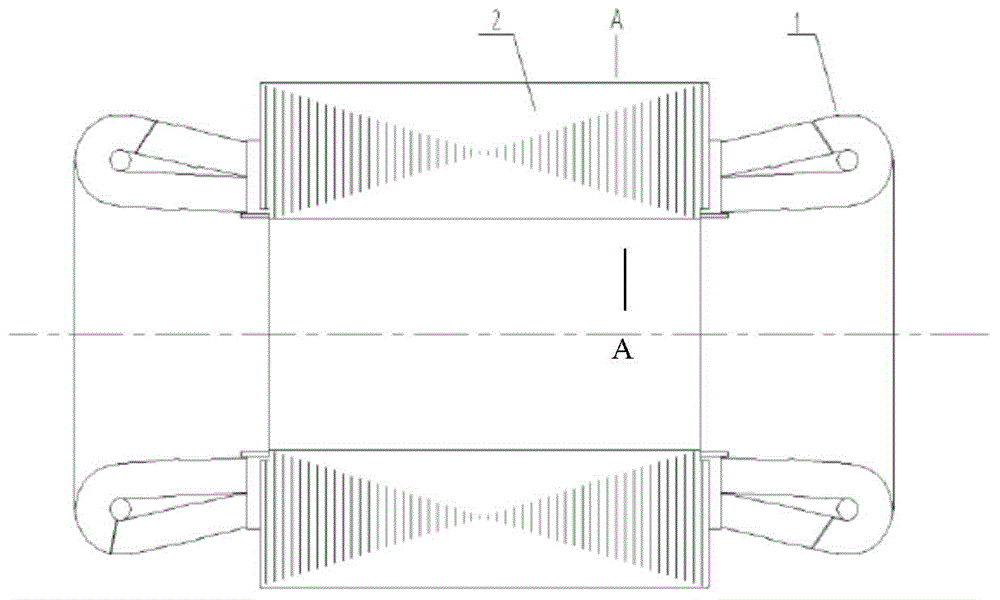

High-heat-conductivity insulating structure and manufacturing method thereof

An insulation structure and high thermal conductivity technology, applied in the shape/style/structure of winding insulation, winding insulation materials, laying solid insulation, etc., can solve the problems of improving manufacturing process, increasing motor manufacturing cost, increasing use requirements, etc., to achieve reduction The effect of operating temperature rise and improving heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

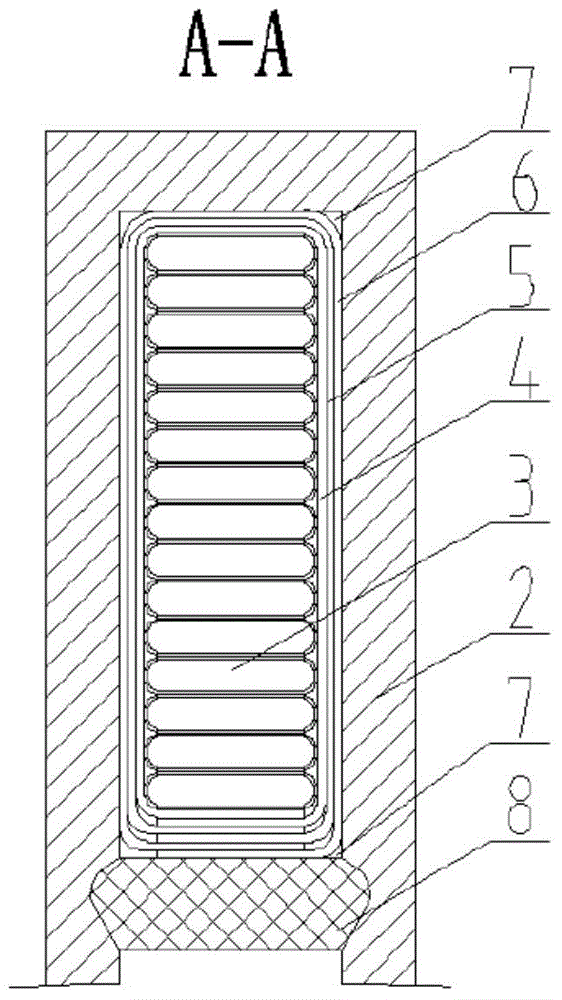

[0024] The manufacturing method of the high thermal conductivity insulating structure provided by the present invention comprises the following specific implementation steps:

[0025] 1) Shuttle winding and expansion of formed coil

[0026] Wind the magnet wire 3 (its insulating layer contains heat-conducting material) on a shuttle machine, keep the tension consistent throughout the winding process, and wrap the wound magnet wire 3 with a white cloth tape (as a protective layer) Afterwards, the expansion and integer are carried out. In this embodiment, the white cloth tape may be an electrical white cloth tape. Optionally, the insulating layer of the magnet wire 3 contains a thermally conductive material, and the thermally conductive material is selected from at least one of metal oxide, metal nitride, diamond, and silicon carbide. For example, aluminum oxide, magnesium oxide, zinc oxide, aluminum nitride, magnesium nitride, zinc nitride, etc.

[0027] 2) Insulation wrappin...

Embodiment 2

[0037] The manufacturing method of the high thermal conductivity insulating structure provided by the present invention comprises the following specific implementation steps:

[0038] 1) Shuttle winding and expansion of formed coil

[0039] Wind the magnet wire 3 (its insulating layer contains heat-conducting material) on a shuttle machine, keep the tension consistent throughout the winding process, and wrap the wound magnet wire 3 with a white cloth tape (as a protective layer) Afterwards, the expansion and integer are carried out. In this embodiment, the white cloth tape may be an electrical white cloth tape. Optionally, the insulating layer of the magnet wire 3 contains a thermally conductive material, and the thermally conductive material is selected from at least one of metal oxide, metal nitride, diamond, and silicon carbide. For example, aluminum oxide, magnesium oxide, zinc oxide, aluminum nitride, magnesium nitride, zinc nitride, etc.

[0040] 2) Insulation wrappin...

Embodiment 3

[0050] The manufacturing method of the high thermal conductivity insulating structure provided by the present invention comprises the following specific implementation steps:

[0051] 1) Shuttle winding and expansion of formed coil

[0052] Wind the magnet wire 3 (its insulating layer contains heat-conducting material) on a shuttle machine, keep the tension consistent throughout the winding process, and wrap the wound magnet wire 3 with a white cloth tape (as a protective layer) Afterwards, the expansion and integer are carried out. In this embodiment, the white cloth tape may be an electrical white cloth tape. Optionally, the insulating layer of the magnet wire 3 contains a thermally conductive material, and the thermally conductive material is selected from at least one of metal oxide, metal nitride, diamond, and silicon carbide. For example, aluminum oxide, magnesium oxide, zinc oxide, aluminum nitride, magnesium nitride, zinc nitride, etc.

[0053] 2) Insulation wrappin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com