Preparation process of oil bleeding type anti-seepage building insulation board

A preparation process and building insulation technology, applied in the field of building insulation, can solve the problems of wall seepage, loose surface, and shorten the service life of insulation boards, so as to improve insulation performance and crack resistance, improve anti-shedding and crack resistance, The effect of improving impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

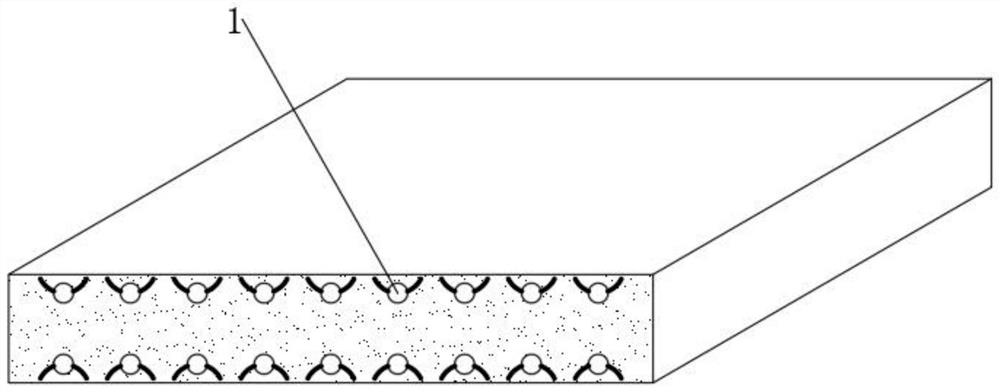

[0043] see figure 1 , a preparation process of an oil-bleeding type anti-seepage building insulation board, comprising the following steps:

[0044] S1. Weigh the following raw materials in parts by weight: 15 parts of Portland cement, 10 parts of fly ash, 10 parts of polypropylene fiber, 5 parts of expanded perlite particles, 4 parts of silicon carbide, 6 parts of functional particles, 10 parts of Inorganic colloid, 4 parts of calcium stearate, 3 parts of foaming agent, 0.5 part of water reducing agent and 20 parts of water;

[0045] S2. Take the above-mentioned raw materials and add them to the mixer for stirring. After uniform mixing, pour them into the mold. During the pouring process, a plurality of oil bleeding anti-seepage balls 1 are pre-embedded in time, and the oil bleeding anti-seepage balls 1 are pre-embedded to maintain oil bleeding. The anti-seepage ball 1 is 1-3cm away from the inner and outer surfaces of the finished insulation board without sinking;

[0046]...

Embodiment 2

[0055] see figure 1 , a preparation process of an oil-bleeding type anti-seepage building insulation board, comprising the following steps:

[0056] S1. Weigh the following raw materials in parts by weight: 20 parts of Portland cement, 12 parts of fly ash, 12 parts of polypropylene fiber, 6 parts of expanded perlite particles, 5 parts of silicon carbide, 7 parts of functional particles, 12 parts Inorganic colloid, 5 parts of calcium stearate, 4 parts of foaming agent, 1 part of water reducing agent and 25 parts of water;

[0057] S2. Take the above-mentioned raw materials and add them to the mixer for stirring. After uniform mixing, pour them into the mold. During the pouring process, a plurality of oil bleeding anti-seepage balls 1 are pre-embedded in time, and the oil bleeding anti-seepage balls 1 are pre-embedded to maintain oil bleeding. The anti-seepage ball 1 is 1-3cm away from the inner and outer surfaces of the finished insulation board without sinking;

[0058] S3. ...

Embodiment 3

[0062] see figure 1 , a preparation process of an oil-bleeding type anti-seepage building insulation board, comprising the following steps:

[0063] S1. Weigh the following raw materials in parts by weight: 25 parts of Portland cement, 15 parts of fly ash, 15 parts of polypropylene fiber, 8 parts of expanded perlite particles, 6 parts of silicon carbide, 8 parts of functional particles, 15 parts Inorganic colloid, 6 parts of calcium stearate, 5 parts of foaming agent, 2 parts of water reducing agent and 30 parts of water;

[0064] S2. Take the above-mentioned raw materials and add them to the mixer for stirring. After uniform mixing, pour them into the mold. During the pouring process, a plurality of oil bleeding anti-seepage balls 1 are pre-embedded in time, and the oil bleeding anti-seepage balls 1 are pre-embedded to maintain oil bleeding. The anti-seepage ball 1 is 1-3cm away from the inner and outer surfaces of the finished insulation board without sinking;

[0065] S3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com