Circuit breaker pole for railway traction lines

A circuit breaker and pole technology, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of large volume of gas insulated switches, difficulty in temperature rise control, and low safety, and improve the protection against dust and water vapor ability, reduce partial discharge, and reduce the size of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

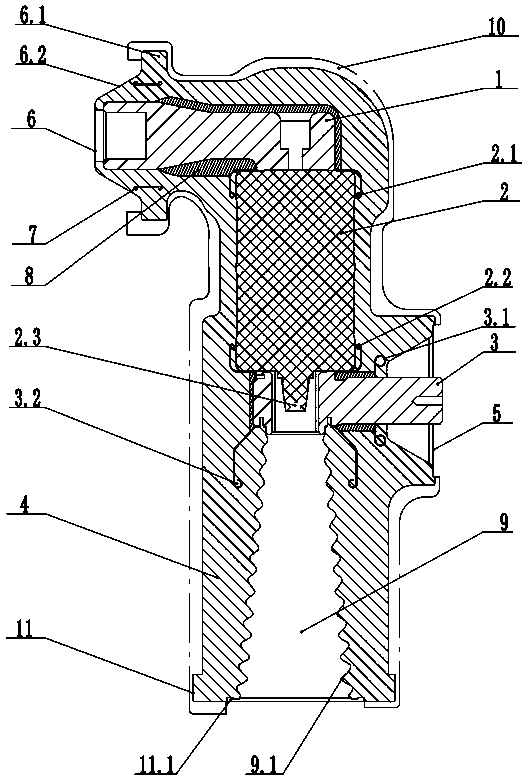

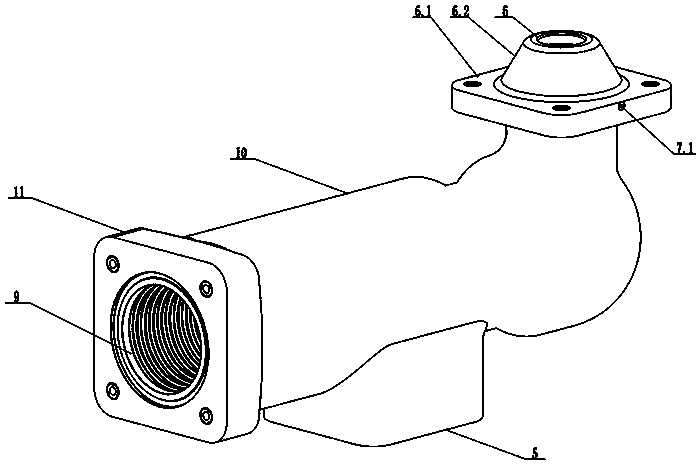

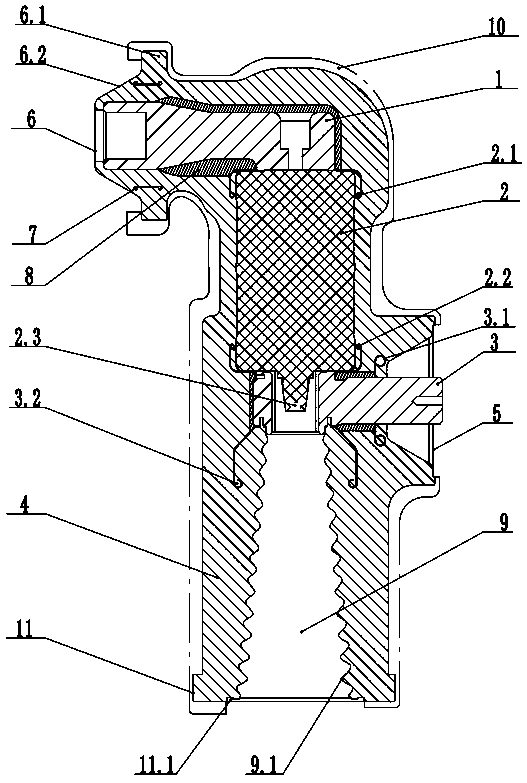

[0013] figure 1 It is a schematic cross-sectional view of the pole of the circuit breaker. For the convenience of illustration, the semi-conductive buffer layer, semi-conductive shield layer and skirt are enlarged. as attached figure 1 and figure 2 As shown, a pole of a railway traction line circuit breaker includes a static end copper conductive part 1, a vacuum interrupter 2, a moving end copper conductive part 3, a rod chamber 9, a semi-conductive buffer layer 8, and a semi-conductive shielding layer 10. There is a semi-conductive buffer layer between the conductor and the part sealed with solid insulating material. The non-connected part of the surface of the solid insulating material is solidified with a semi-conductive shielding layer. There are pressure equalizing parts at the connection of conductors to eliminate the phenomenon of partial tip discharge.

[0014] The copper conductive part 1 at the static end is fastened to the copper conductive part at the static ...

Embodiment 2

[0018] The solid insulating material is epoxy resin. The pressure equalizer is made of 0.5 mm thick stainless steel mesh.

[0019] All the other are with embodiment 1.

Embodiment 3

[0021] The solid insulating material is EPDM rubber. The pressure equalizing part is made of carbon fiber through mold processing, and the thickness of the pressure equalizing part is 1-2 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com