Insulating film

An insulating film and insulation technology, applied in the direction of insulators, insulators, insulated conductors, etc., to achieve the effects of long insulation life, excellent heat resistance and discharge degradation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] Hereinafter, the present invention will be specifically described by way of examples, but the present invention is not limited by these examples. However, the measurement methods in Examples and the like are as follows.

[0050] (1) Weight average molecular weight

[0051] The weight average molecular weight is measured in terms of polyethylene oxide (PEO) using gel permeation chromatography (GPC). GPC conditions are shown below.

[0052] GPC device: product name "HLC-8120GPC" (manufactured by Tosoh Corporation)

[0053] Column: "TSK gel super AWM-H" + "TSK gel super AW4000" + "TSK gel super AW2500" (manufactured by Tosoh Corporation)

[0054] Flow: 0.4ml / min

[0055] Concentration: 1.0g / l

[0056] Injection volume: 20μl

[0057] Column temperature: 40°C

[0058] Eluent: 10mM-LiBr+10mM-phosphoric acid / DMF

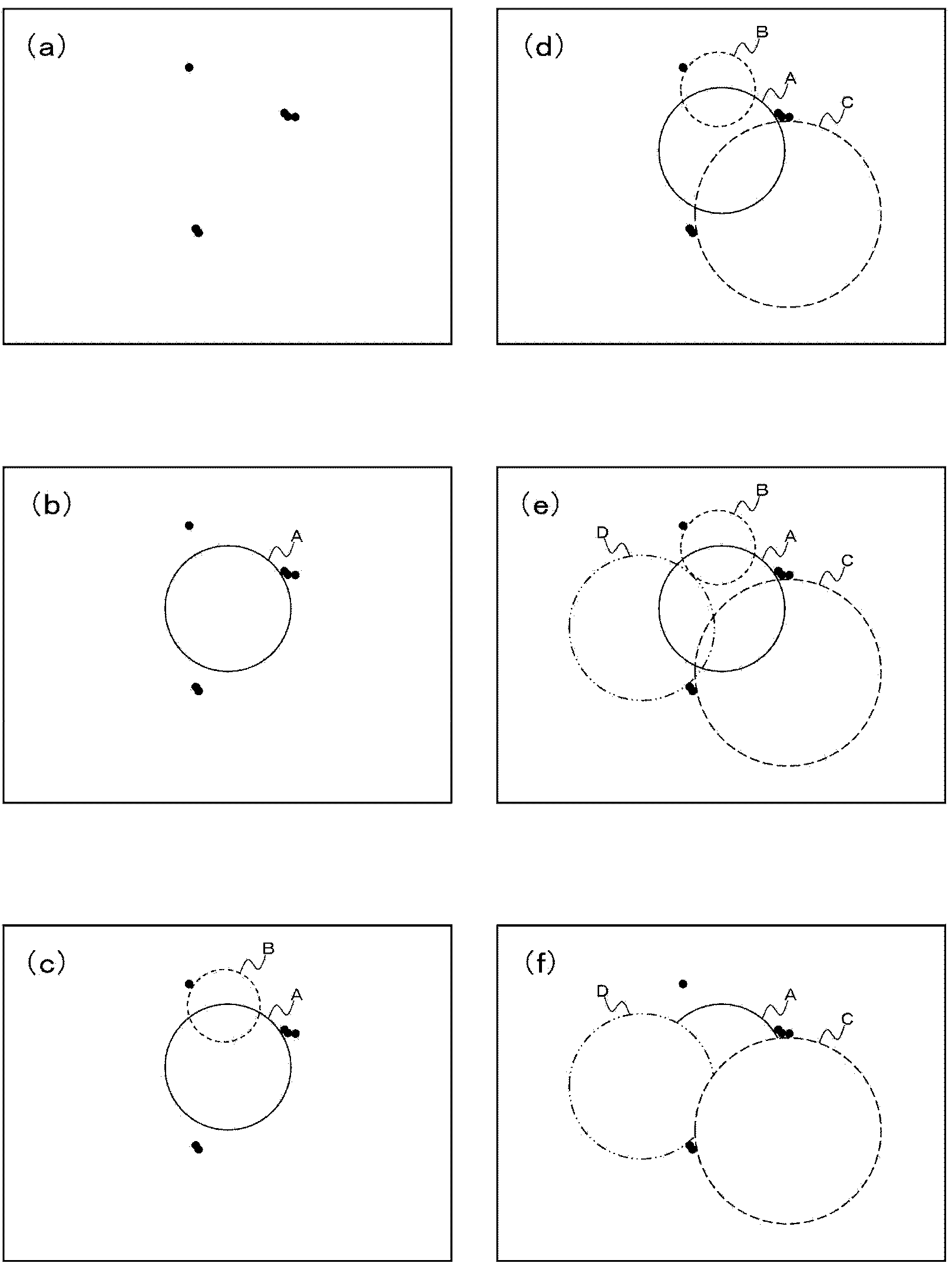

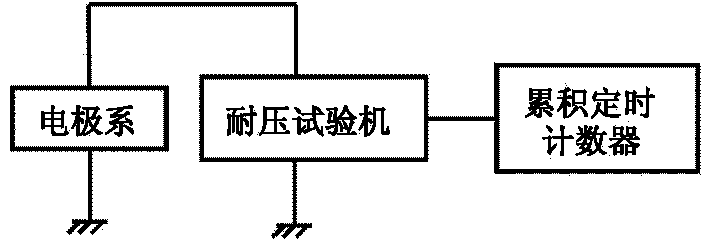

[0059] (2) Insulation life time

[0060] Using a withstand voltage tester (product name "5051A", manufactured by Tsuruga Electric Corporation), the applied ...

Synthetic example 1

[0066] Add 1.00 mol of trimellitic anhydride (TMA), 1.00 mol of diphenylmethane diisocyanate (MDI) and 1063 g of N-methyl-2-pyrrolidone (NMP) into a four-neck flask equipped with a mechanical stirrer with stirring blades, °C for two hours. Then, the temperature was raised to 180° C., and the reaction was carried out for 3 hours. Thus, a polyamideimide varnish was obtained. The weight average molecular weight of the obtained polyamideimide resin was 65,500. In addition, the resin solid content of the obtained polyamideimide varnish was adjusted to 25% by weight, and the adjusted varnish (solvent: NMP) was measured at 25% by weight using a digital viscometer HBDV-I Prime (manufactured by Brookfield Engineering Laboratories, Inc.). The viscosity at ℃ was 66.4Pa?s.

Embodiment 1

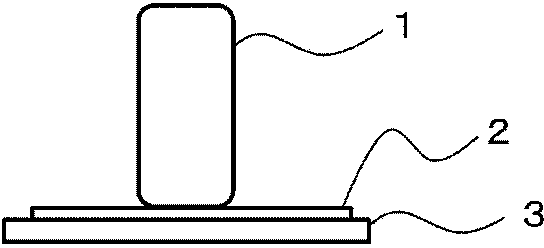

[0068] Add nano-silica (product name "AEROSIL (R) RA200H", produced by Nippon Aerosil Co. Ltd.), so that the added amount was 2.5 parts by weight relative to the solid content of the resin, and dispersed using a roll mill. The obtained silica dispersion varnish was so that the thickness after drying was 50 μm Coated on a glass substrate. It was heated at 80°C for 15 minutes, then heated at 150°C for 15 minutes, and after cooling to room temperature, it was released from the glass substrate to obtain an independent semi-cured film. Fix the semi-cured film The end of the cured film was further heated at 340° C. for 15 minutes to obtain a cured film of polyamideimide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com