Bearing mounting structure and heat-conducting grease filling method

A technology of installation structure and thermal grease, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, pump components, etc., can solve problems such as poor heat dissipation performance, and achieve extended operating life and axial load bearing Uniform and prevent overheating and burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

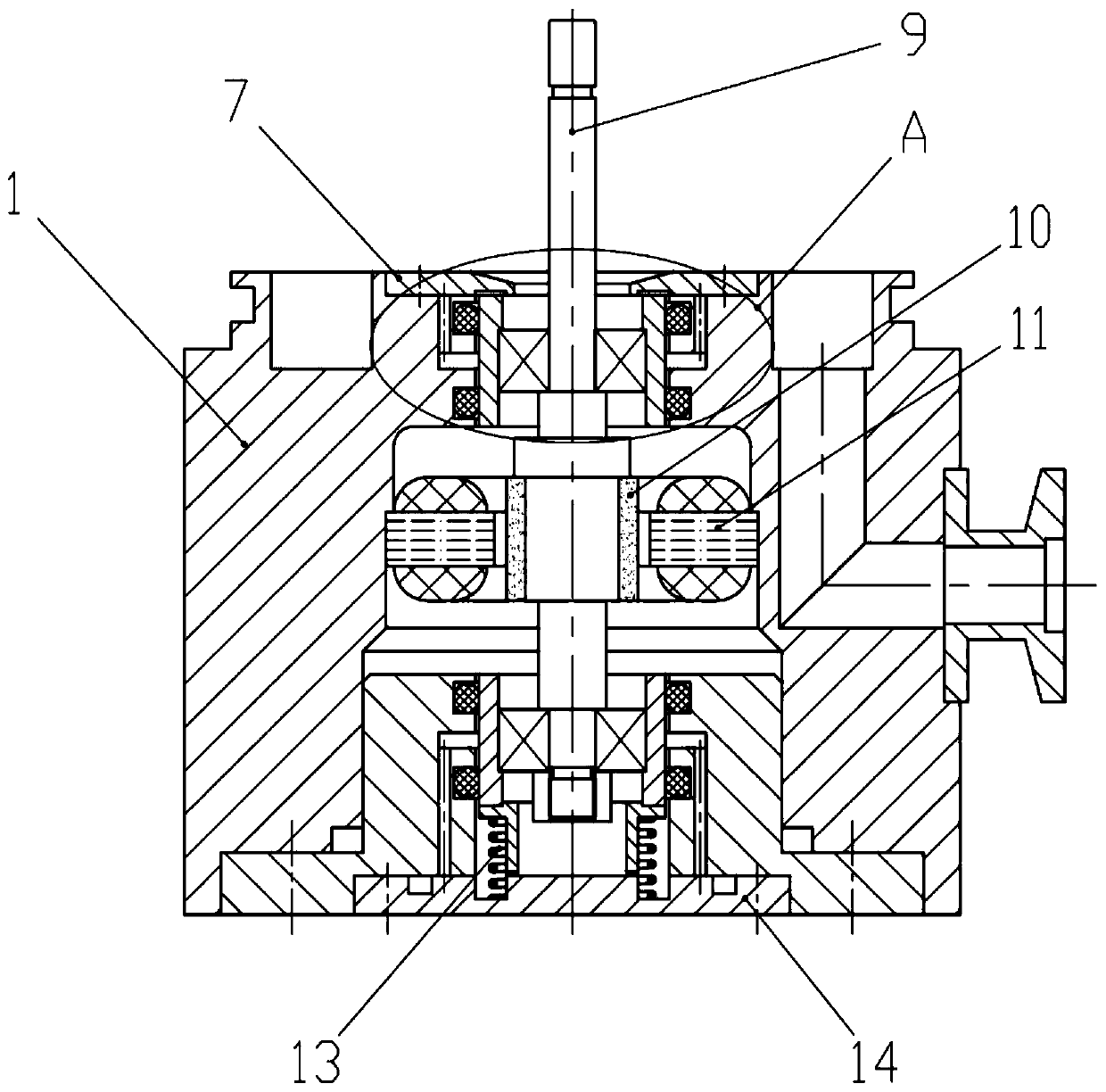

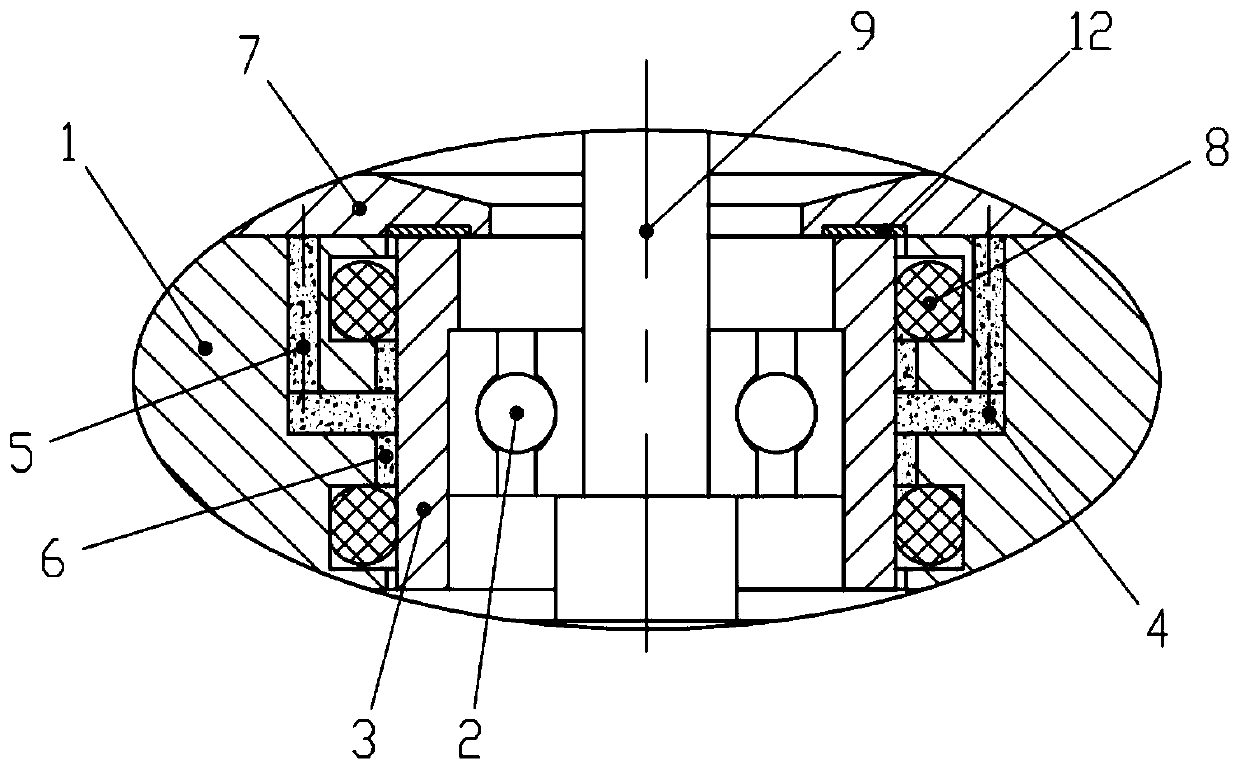

[0033] The following combination figure 1 and figure 2 , an embodiment of the present invention is described:

[0034] Bearings at both ends of the main shaft 9 of the small molecular pump generally adopt the same type, so the same cooling structure can be used. After the bearing bushing 3 and the bearing 2 are assembled, they are installed on both ends of the main shaft 9 respectively, and the main shaft is installed in the bearing seat 1 with the vibration-damping O-ring 8 . An annular cavity 6 is formed between the bearing seat 1, the bearing bush 3, and the double-layer damping O-ring 8, and the outside of the annular cavity 6 communicates with the annular grease groove 4 provided on the bearing seat 1, and the outside of the grease groove 4 The end is provided with a grease injection hole 5 communicating with it. Two grease injection holes 5 are opened symmetrically along the axis of the bearing housing 1 . Use a syringe to fill the grease injection hole 5 at one end ...

Embodiment 2

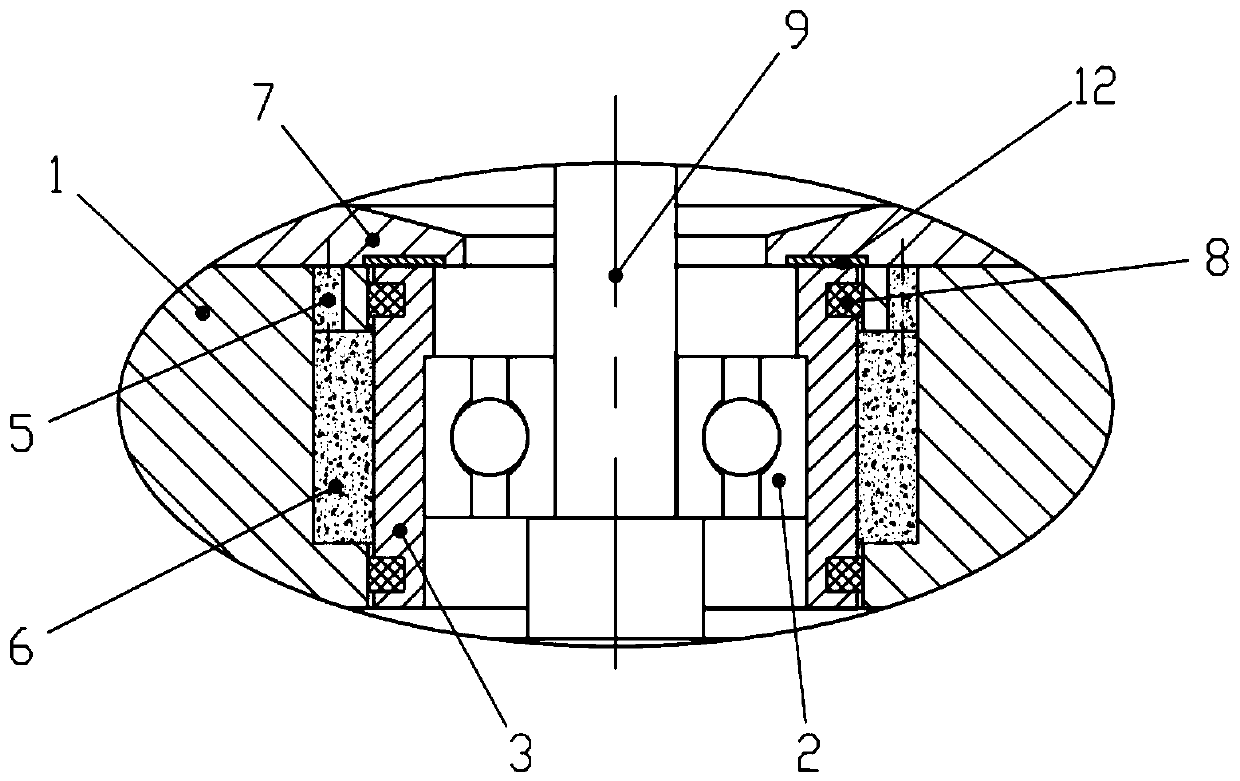

[0040] As an alternative implementation, such as image 3 As shown, when the molecular pump uses a smaller bearing (inner hole 6mm or less), due to the use of double-layer O-rings for vibration reduction, the cross-sectional area of the vibration-damping O-ring 8 can be smaller, for example image 3 The O-ring with a rectangular cross-section is shown, and the supporting structure of the O-ring can be set on the bearing bush 3. The outer wall of the annular cavity 6 on the bearing seat 1 can be extended outward appropriately, and the annular cavity 6 can be directly connected to the grease injection hole 5 (that is, without The grease injection groove described in Embodiment 1) is connected, so that the grease injection path can be shortened, and the grease injection resistance is smaller, so as to ensure that the thermal conductive grease fills the annular cavity 6 .

[0041] Using the above-mentioned bearing installation structure, according to the molecular pump shafting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com