Self-adhering friction reducing liner and method of use

a friction reducing liner and self-adhering technology, applied in the field of self-adhering friction reducing liner and method of use, can solve the problems of single cycle damage, tissue damage, tearing of biological tissues such as blood capillaries and interface (skin-subcutaneous) layers, and achieve the effects of minimizing friction coefficient, minimizing friction, and high friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

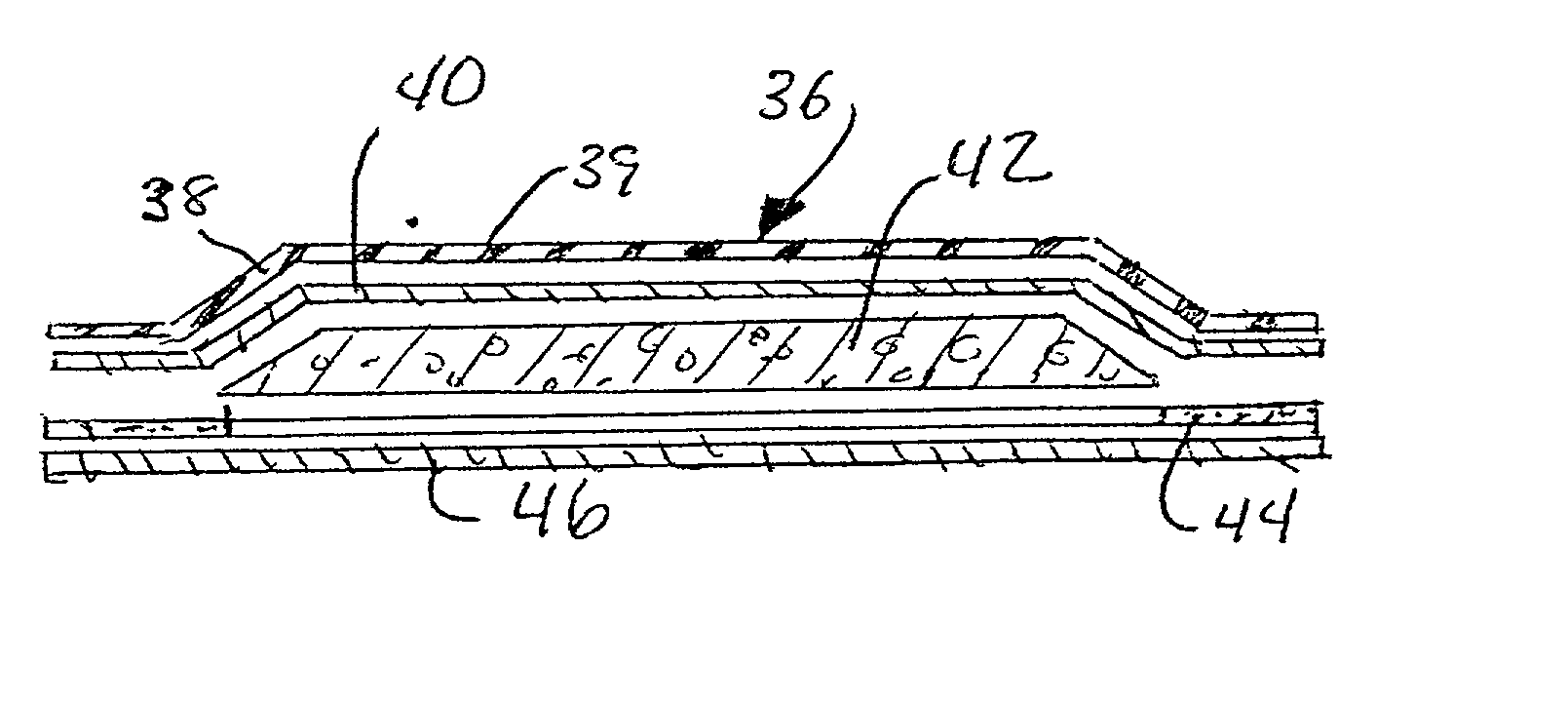

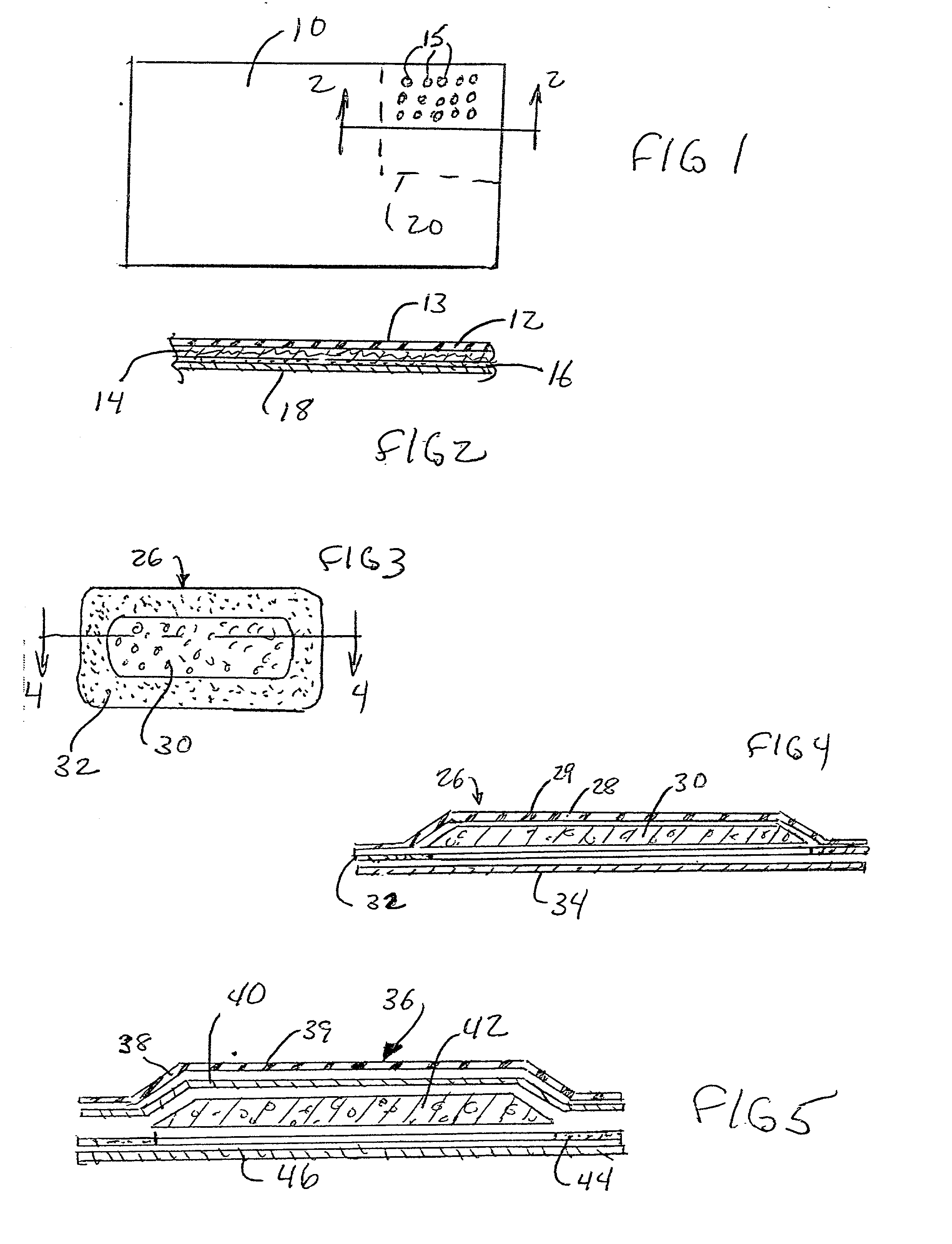

[0040] FIGS. 1 and 2 illustrate a simple form of the invention which includes a composite sheet 10 made in a suitable size, which can be used for cutting individual interface patches or pieces from the sheet. The composite sheet 10 includes a thin film or layer 12 of polytetrafluoroethylene (PTFE). Layer 12 is preferably bonded to a stretch fabric layer 14, such as Lycra or stretch nylon, which also is relatively thin. The top layer of PTFE can be in the range of 2.5 mils thick, and the layer of fabric 14 could be slightly thicker than that, as needed to make a suitable stretch weave. The PTFE film 12 is conformable and will stretch, so that the stretch fabric will cause the PTFE layer to move with it, if it is stretched in any direction. A thin layer of adhesive 16 is shown in the drawings on an opposite side or surface of fabric layer 14 from the PTFE layer 12. A suitable release paper 18 is provided over the adhesive on the fabric.

[0041] The sheet 10 can be used for cutting out v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com