Finite element modeling method based on real material microstructure

A technology of microstructure and modeling methods, applied in 3D modeling, image data processing, instruments, etc., can solve problems such as unacceptable, achieve the effect of suppressing noise, saving programming process, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

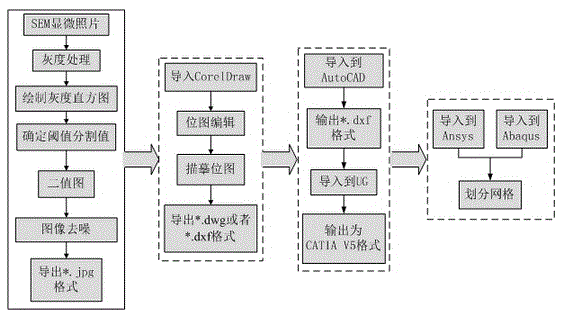

[0048] The present invention belongs to the pre-processing part of finite element modeling, combines digital image processing technology, and the technology of converting bitmap into vector diagram. On the basis of the real microstructure of the material, the microvoids and inclusions in the material structure are represented in the numerical simulation. The main auxiliary software used are: Photoshop, CorelDraw, AutoCAD, UG, Ansys, ABAQUS, etc. The present invention skips the tedious programming process and directly operates on the basis of the existing mature software. The operation is simple and easy to be accepted by beginners. The following is an analysis of the APS-TBCs (thermal barrier coating) materials coated on the turbine blades of aerospace engines.

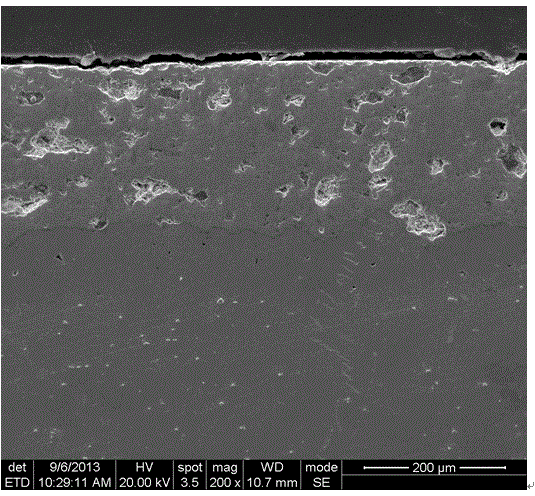

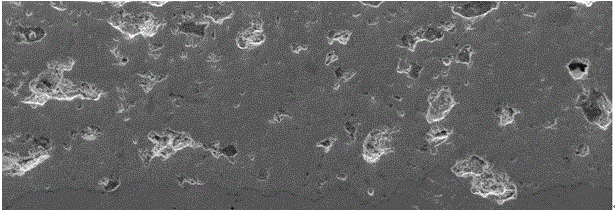

[0049] During the production process of APS-TBCs (plasma sprayed thermal barrier coatings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com