Method for machining J-shaped grooves of series of pipe socket holes in thin-wall irregular spherical end socket

A spherical head and processing method technology, applied in the field of parts processing, can solve the problems of inability to guarantee dimensional accuracy, surface roughness, series of hole processing procedures, etc., and achieve the effect of improving surface quality and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

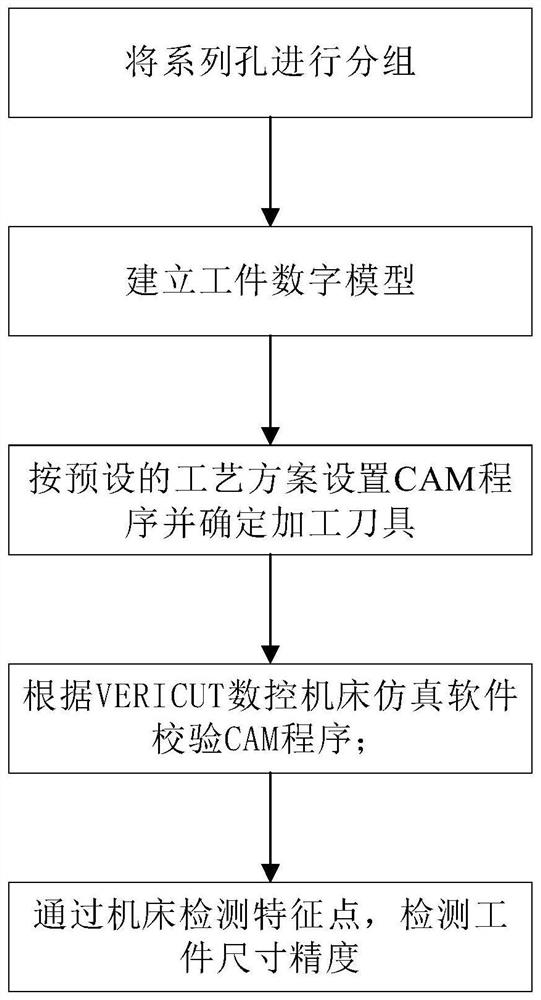

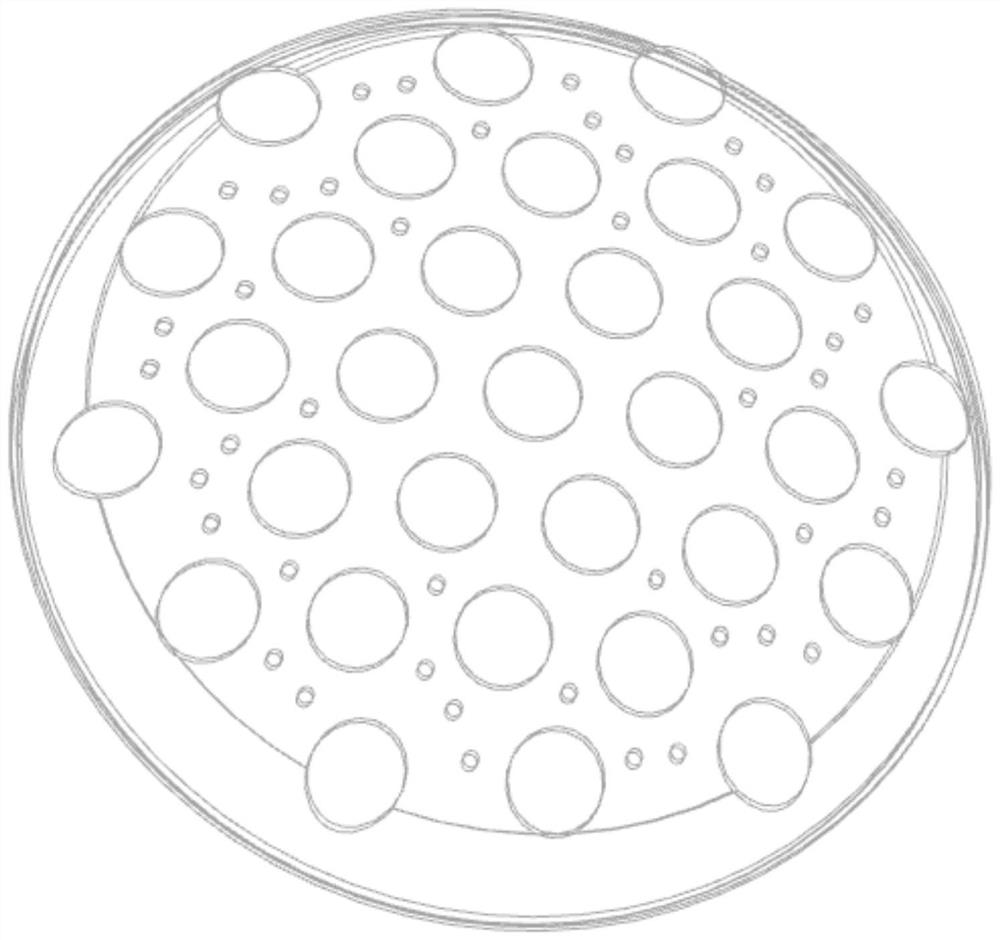

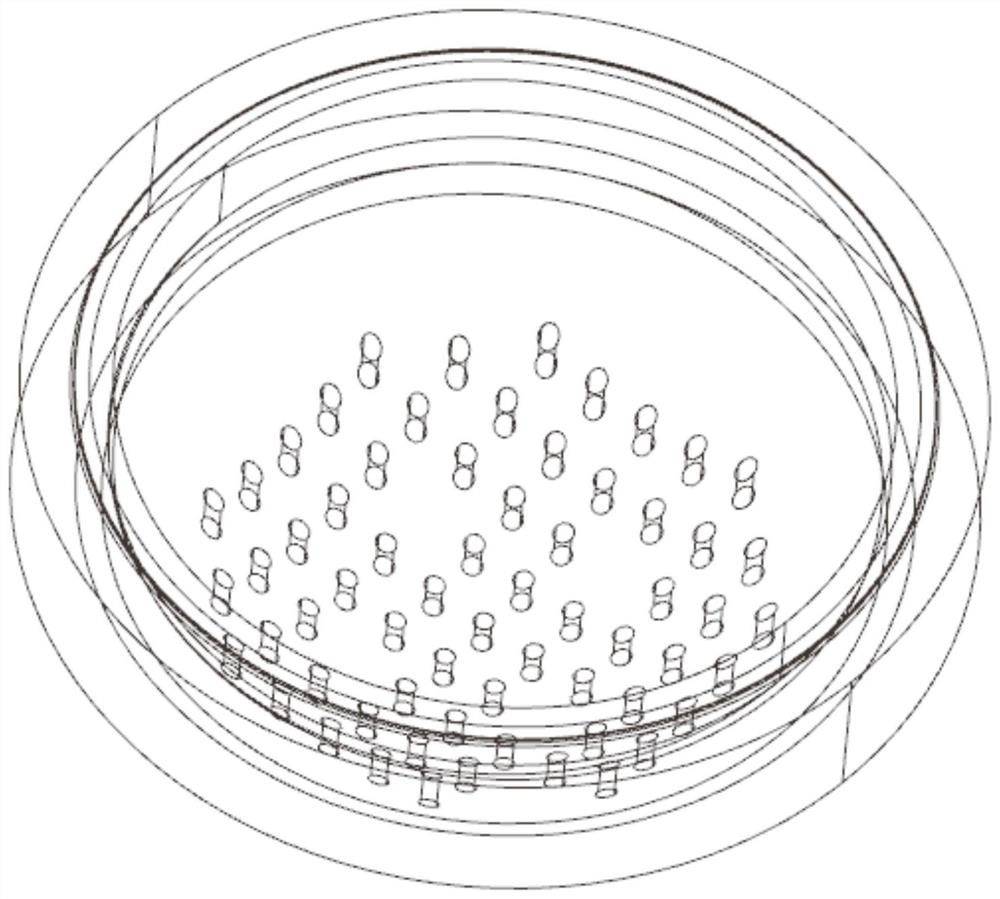

[0057] As an embodiment of this application, in combination with Figure 2-7 The numerical control processing method described in the present application is further explained, and the content mentioned above will not be repeated here, and further explanations will be given for specific examples.

[0058] Such as Figure 2-3 As shown, in the processing process, the holes to be processed need to be grouped first, which can better simplify the processing. figure 2 , 3 It shows the grouping of processing holes on the outer wall of the ball and the inner wall of the ball respectively. It can be seen that the method described in this application not only supports the support on the outer wall of the ball but also can be used on the inner wall of the ball.

[0059] Specifically, firstly, the head is clamped with the J-groove side upwards, and placed according to the predetermined orientation. G54X0Y0 is set at the center of rotation of the head. At this time, each hole where the J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com