Measuring device and measuring method for coaxiality of horizontal punching punch of multi-directional die forging hydraulic press

A technology of coaxiality measurement and multi-directional die forging, which is applied to mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problems of reducing the overall life of the forging die, damage, punch breakage, etc., to ensure the quality of the external dimensions. , obvious economic benefits, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

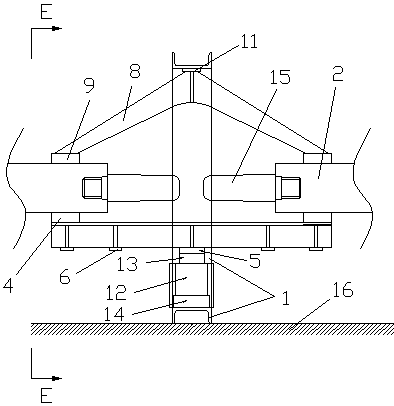

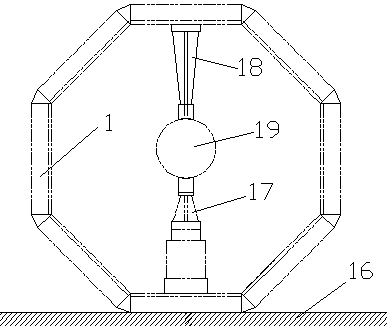

[0092] The present invention is described in detail below with reference to accompanying drawing and embodiment:

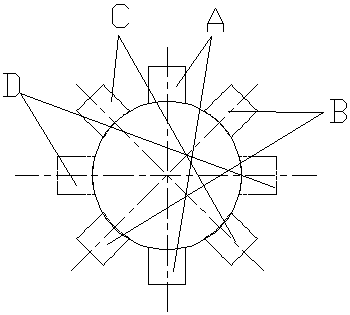

[0093] The principle of the multi-directional die forging hydraulic press horizontal piercing punch coaxiality measuring device of the present invention is as follows: figure 1 As shown, the specific description is as follows: the use of this measuring device is based on the principle of concentric circles, that is, the cross-sectional circle of the cylindrical surface formed by the arc-shaped contact surface of the arc-shaped slider at the positions of the four measuring directions is concentric with the cross-section circle at the root of the horizontal punch Circle, the shortest distance from any point on one circle to the other circle is equal everywhere, which means that in actual measurement, under the action of orthogonal balance force, the gap between the arc slider and the cylindrical contact surface at the root of the horizontal punch is equal everywhere....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com