Threaded rib anchor rod steel bar hot rolling process and device

A ribbed anchor rod and steel bar technology, which is applied in the hot rolling process and device field of threaded rib anchor rod steel bars, can solve the problems of low production efficiency, high requirements for the height of transverse ribs, K1 bursting grooves, etc., and achieve improved production efficiency and excellent dimensional accuracy , The effect of reducing rolling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

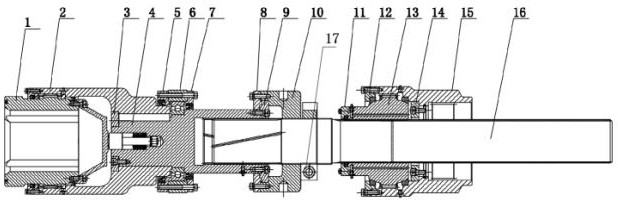

[0018] refer to figure 1 As shown, the present invention provides a hot-rolling process for threaded rib anchor bars. The steps include: after the steel bar is rolled out of a circular shape in the rough rolling stage, the roll passes used in the finish rolling stage are: flat rolling holes type, vertical box pass, pre-cut pass, split pass, flat ellipse pass and threaded rib pass; among them, the K1 roll phase connection shaft adopts the crankshaft connection shaft, and the inner ring gear of the control reducer is connected with it. When the two output shafts of the matching reducer do not rotate, the relative rotation of the outer gear sleeve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com