Technological method applied to guaranteeing micro-milling machining precision of folded waveguide slow-wave structure

A technology of slow-wave structure and folded waveguide, which is applied in metal processing equipment, metal processing machinery parts, milling machine equipment, etc., can solve the problems of restricting the size, shape and position accuracy of slow-wave structures, so as to ensure the consistency of depth and improve the vertical degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

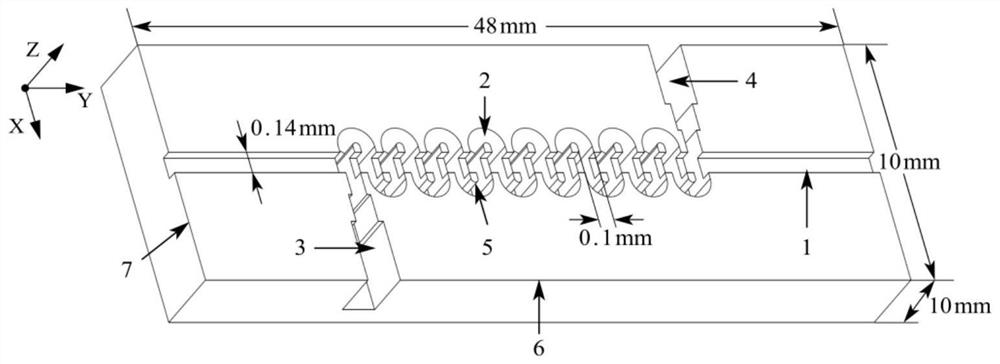

[0070] A process method applied to the micro-milling of folded waveguide slow-wave structures to ensure the machining accuracy, which is used for machining such as figure 1 The slow-wave structure shown. The overall slow-wave structure is a cuboid of 48mm*10mm*10mm. S-shaped grooves 2 and straight grooves 1 that penetrate each other are distributed on the upper surface of the cuboid, and the two intersect to form isolated islands 5 . Among them, the S-shaped groove has a total of 75 cycles, the aspect ratio of the S-shaped groove reaches 255 μm / 100 μm, the width of the island is 48 μm, the span is 22.2 mm, and the width of the straight groove is 140 μm. The material of the slow-wave structure is doped with Al with a volume fraction of 0.5% to 1.2% and a particle size of 50 to 100 nm. 2 O 3 Particles of dispersed oxygen-free copper. The dimensional accuracy of the processed slow-wave structure is required to be better than ±2μm, and the surface roughness Ra should be better...

Embodiment 2

[0076] A process method applied to the micro-milling of folded waveguide slow-wave structures to ensure the machining accuracy, which is used for machining such as figure 1 The slow-wave structure shown. The overall slow-wave structure is a cuboid of 48mm*10mm*10mm. S-shaped grooves 2 and straight grooves 1 that penetrate each other are distributed on the upper surface of the cuboid, and the two intersect to form isolated islands 5 . Among them, the S-shaped groove has a total of 75 cycles, the aspect ratio of the S-shaped groove reaches 255 μm / 100 μm, the width of the island is 48 μm, the span is 22.2 mm, and the width of the straight groove is 140 μm. The material of the slow-wave structure is doped with Al with a volume fraction of 0.5% to 1.2% and a particle size of 50 to 100 nm. 2 O 3The dispersed oxygen-free copper of the particles, the volume fraction of the dispersed oxygen-free copper doping in this example is 1.1%. The dimensional accuracy of the processed slow-w...

Embodiment 3

[0122] Compared with the second embodiment, the basic requirements of the processed slow-wave structure are the same in this embodiment.

[0123] Compared with the second embodiment, the process steps of the present embodiment are omitted in step B1, the other steps are the same as the process method, and the cutting parameters are slightly adjusted within the selection range. The experimental results show that after using the process steps of this embodiment, ZYGO white light interferometer and VHX-1000 ultra-depth-of-field optical microscope are used to measure the dimensional accuracy and surface topography of the workpiece, and the shoulder burrs of the slow-wave microstructure are basically eliminated, and the adjacent processing units There is no obvious dislocation at the junction, the contour accuracy is good, the verticality of the side wall is high, and the thin-walled island structure has no local collapse. Within, the surface roughness Ra is better than 60nm. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com