Skeleton assembly process of full-loading passenger car

A full load-bearing and skeleton technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of high difficulty and small operating space of assembly process, and achieve high feasibility, ensure accuracy, and meet the effect of dimensional accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

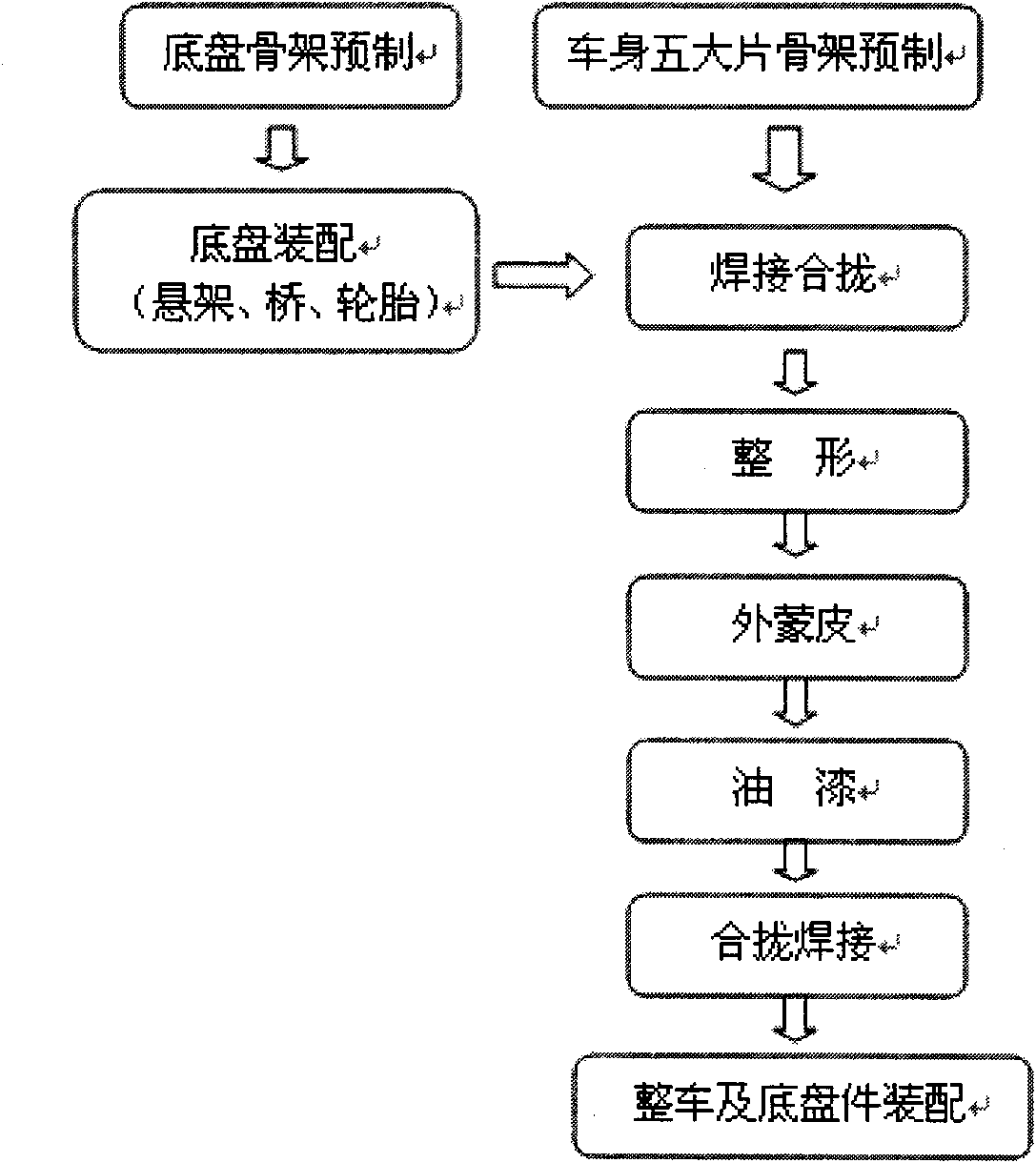

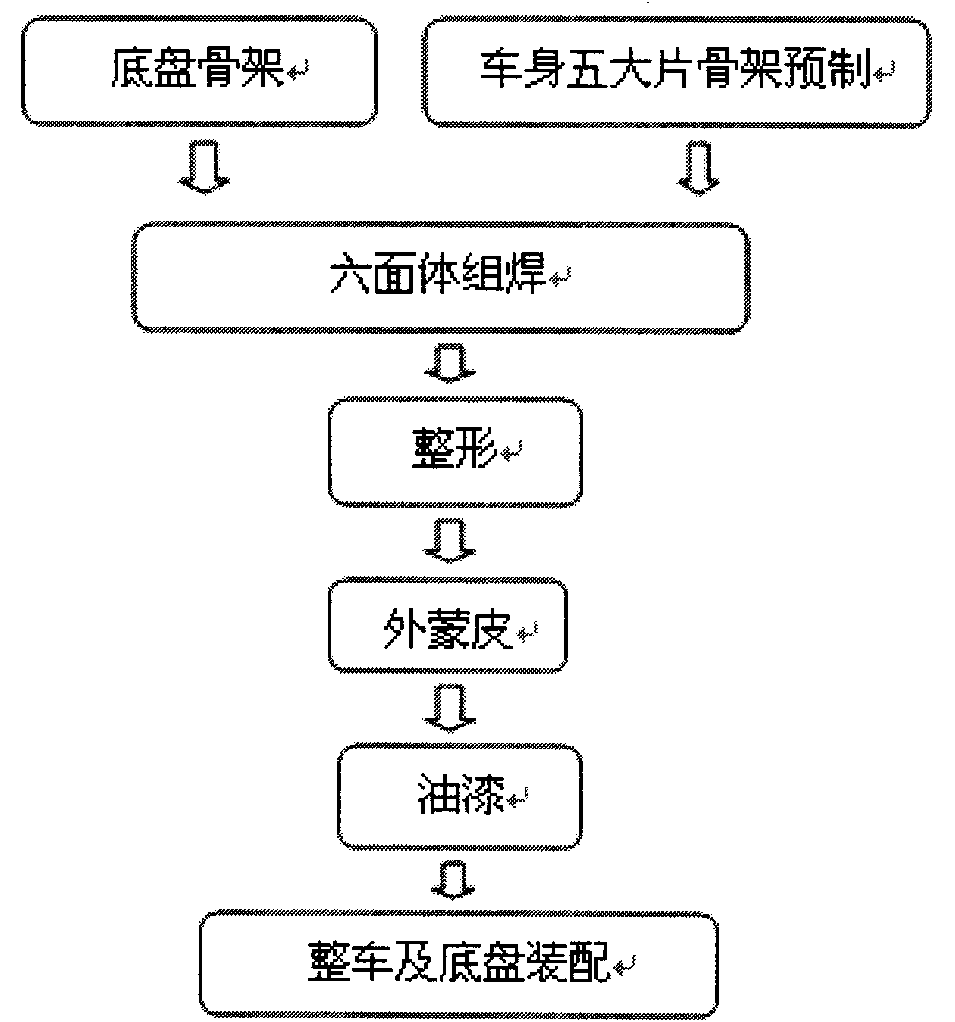

[0014] Such as figure 1 As shown in the figure, after the chassis skeleton is prefabricated, it is directly sent to the chassis assembly station for suspension, bridge and tire assembly. In order to avoid heavy deformation, the engine, gearbox and other chassis components are not assembled here. Then, the five prefabricated car body skeletons and the assembled underframe are welded together at the hexahedron assembly welding station described in prior art 1. Afterwards, operations such as shaping, outer skinning, and painting can be carried out according to the flow described in the existing process 1. Finally, the engine, gearbox, steering system, braking system and other chassis parts are scattered on the vehicle assembly line for vehicle assembly.

[0015] The above is only a preferred embodiment of the present invention, and is not intended to limit the present invention. Any minor modifications, equivalent replacements and improvements made to the above embodiments acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com