Method for designing blade blank for electrolytic machining

A design method and blade technology, applied in electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, easy deformation, poor precision, etc., and achieve high processing efficiency, long processing time, and qualified rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

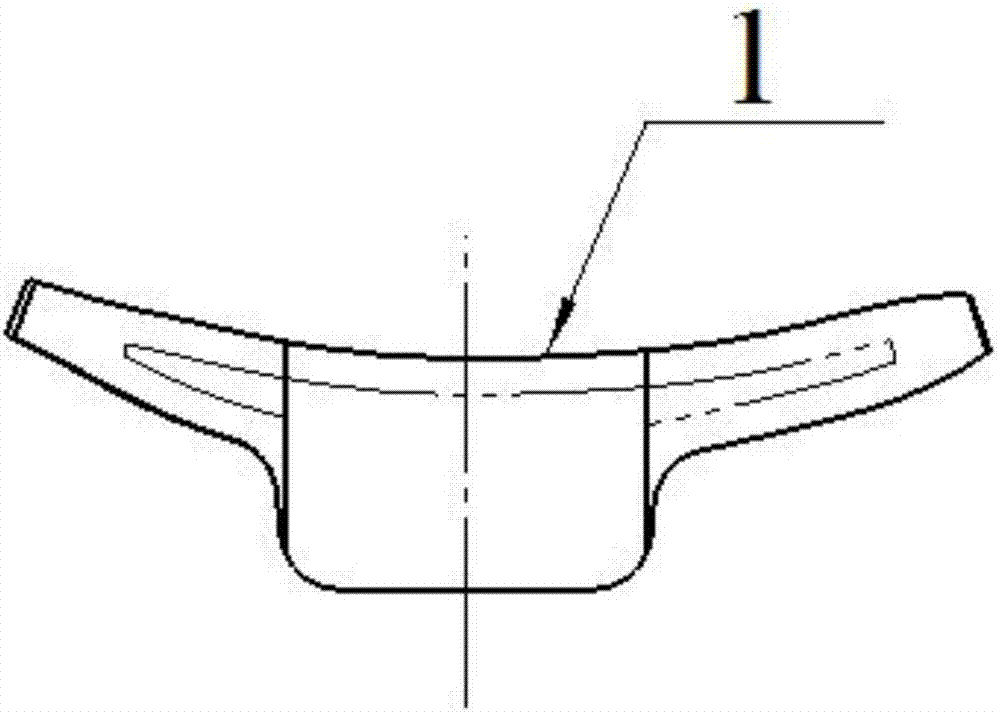

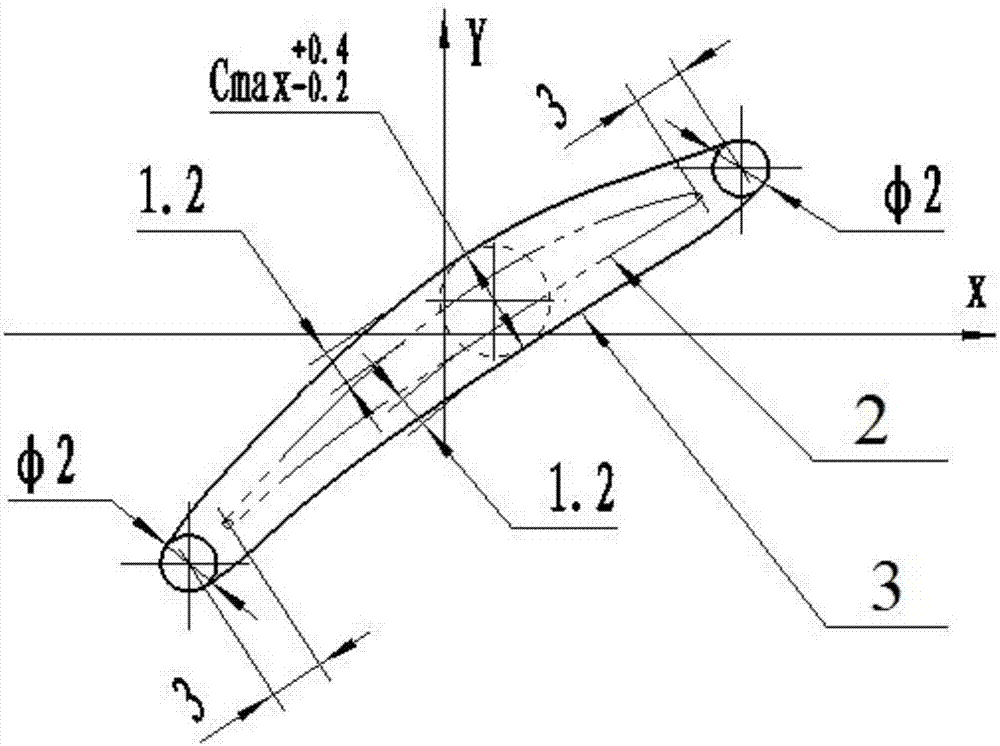

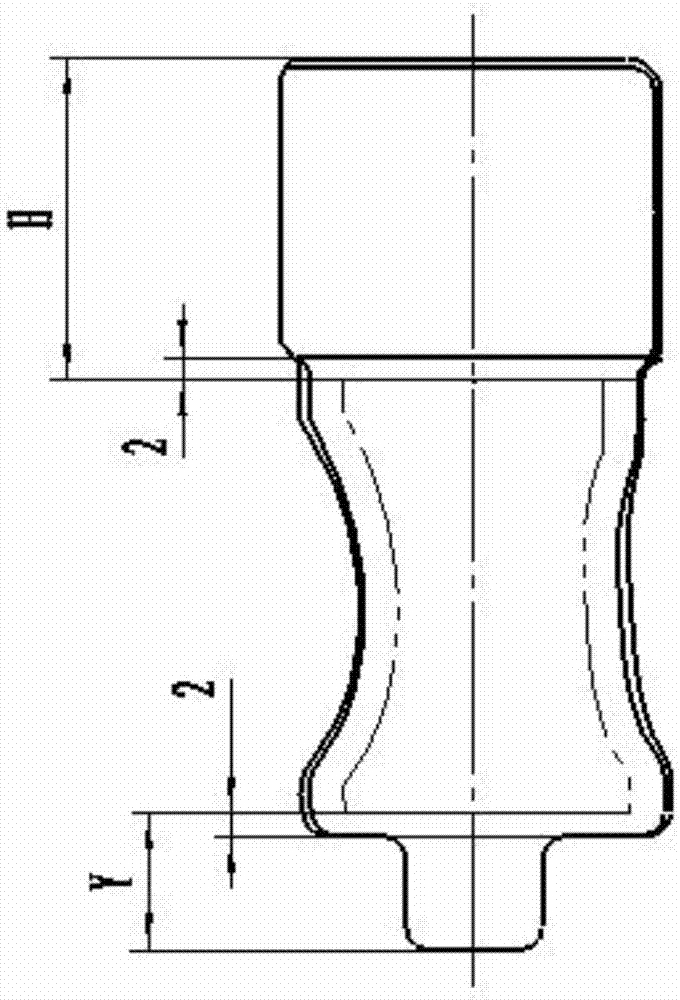

[0022] A blade blank design method for electrolytic machining, the blade is a compressor stator blade without a mounting plate, made of GH4169 superalloy, such as image 3 As shown, the blade blank is composed of three parts: the mounting plate, the airfoil profile, and the process boss, and is designed from the following four aspects:

[0023] (1) Design of the mounting plate: a mounting plate is added at the blade root, the mounting plate is designed as a rectangle of 25mm (length) × 32mm (width) × 10mm (thickness), and the mounting plate is designed after the effective part size is extended by 2mm , so that the length H of the mounting plate can be completely processed after the electrolysis of the blade body is completed (see image 3 ).

[0024] (2) The design of the process boss: a process boss is added at the blade tip. The shape of the process boss is a cuboid. After the effective size of the blade tip is extended by 2mm, the process boss is designed. The process boss a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com