Method for machining spatial curved surface of large conical surface connecting pipe on three-axis linkage milling machine

A technology of three-axis linkage and processing method, which is applied in the direction of milling machine equipment, metal processing equipment, milling machine equipment details, etc., can solve the problems of unguaranteed dimensional accuracy and surface roughness, shortage of technical personnel, expensive five-axis machine tools, etc., to achieve optimization Effects of processing scheme, improving surface quality and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

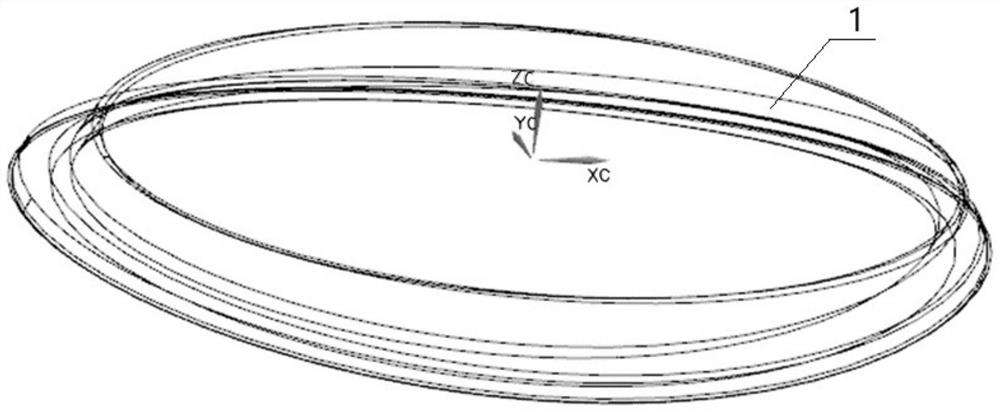

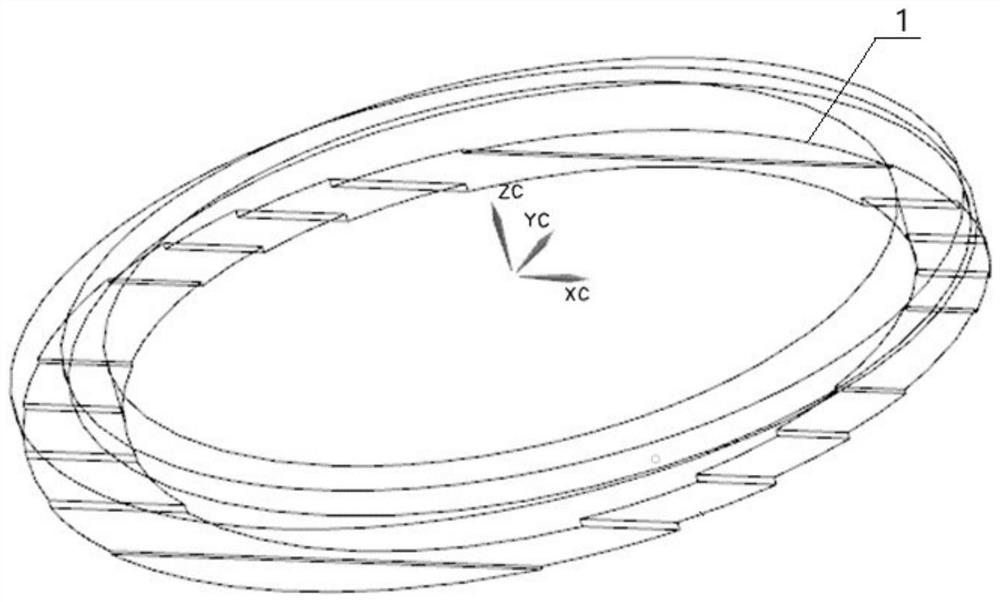

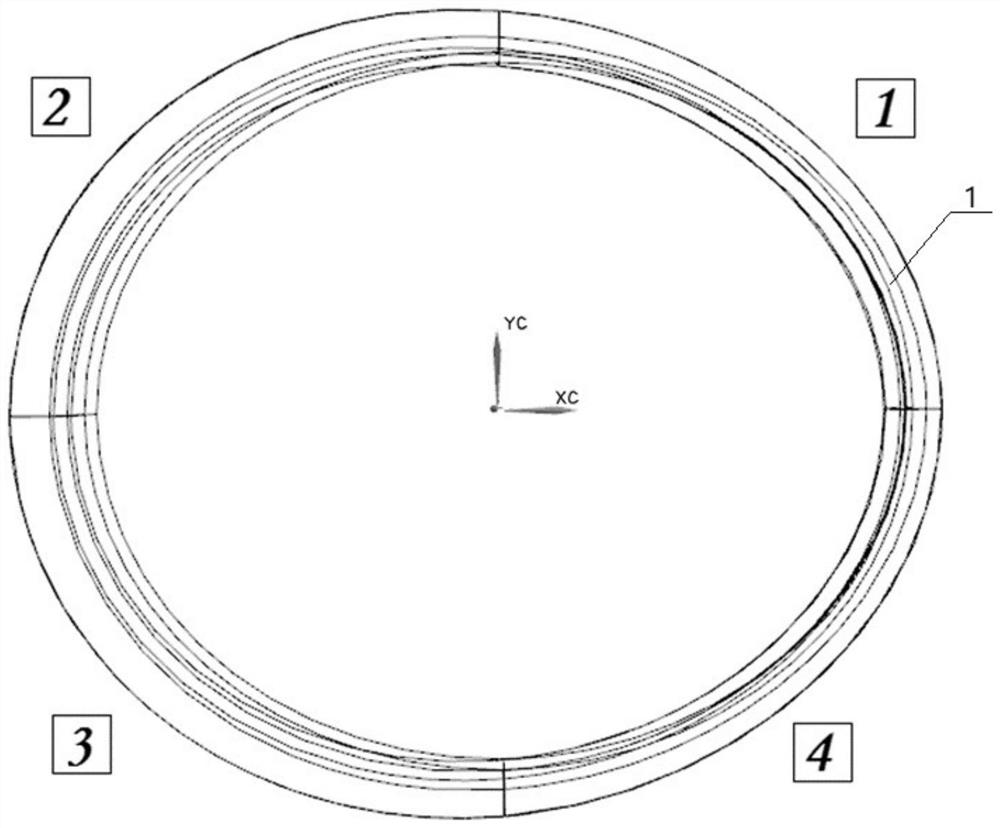

[0037] The present invention is a processing method of a large-scale conical surface connecting space curved surface on a three-axis linkage milling machine, such as figure 1 As shown, the design requirement of the workpiece 1 is a space curved surface formed by the intersection of a cylinder and a cone. The processing method of the present invention is mainly used for processing a complex space surface in which the cylinder intersects with the side of the cone to form a positive angle on one side and a negative angle on the other. , At the same time, the angle milling head processing scheme adopted in the present invention provides a valuable solution for processing similar bidirectional internal angle structures.

[0038] The following is processed as figure 1 The space surface shape shown is taken as an example, combined with Figure 1-Figure 6 The technology of the present invention is described further in detail.

[0039] 1. Establish a three-dimensional model of workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com