Panel moving mechanism of trimming machine

A technology of moving mechanism and edge sawing machine, which is applied in the directions of grinding machine tool parts, grinding feed movement, grinding workpiece support, etc., which can solve the problems of large power consumption and long plate transportation route, and achieve simple and convenient maintenance, The effect of pressing the plate is stable and the effect of power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

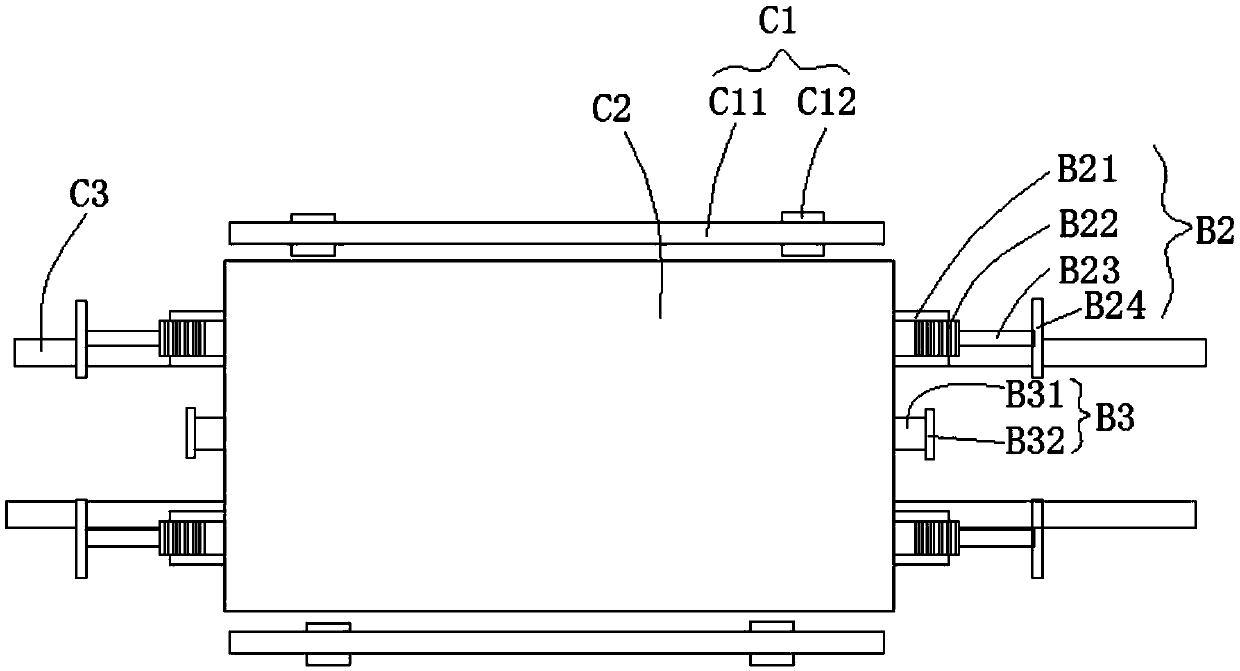

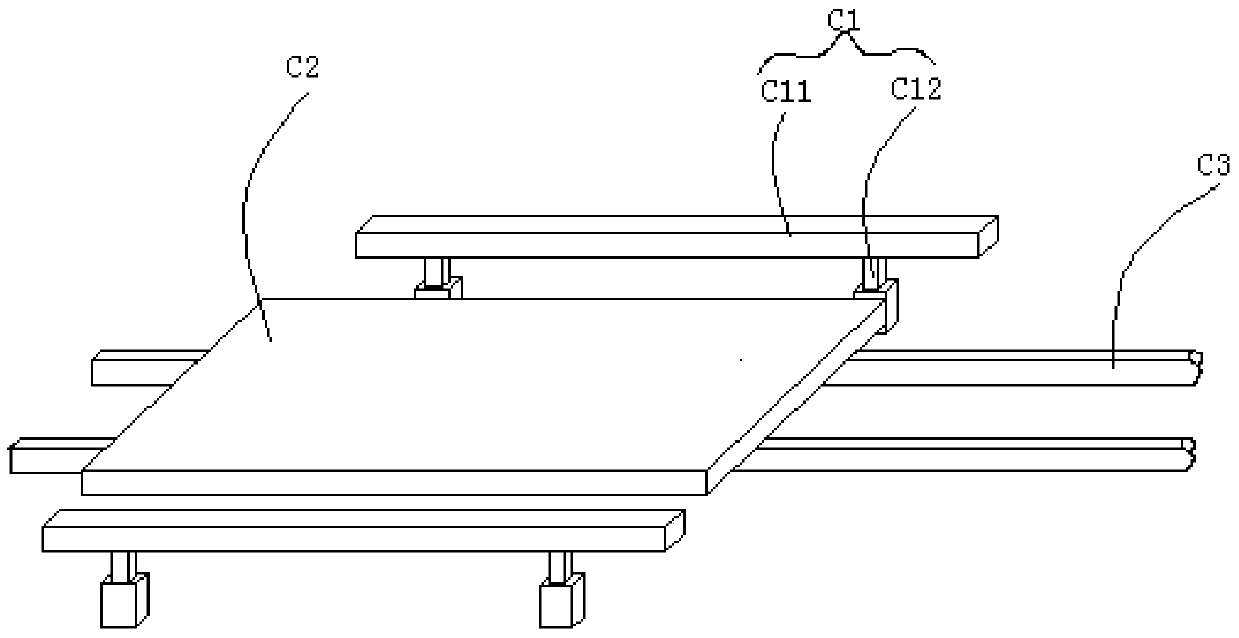

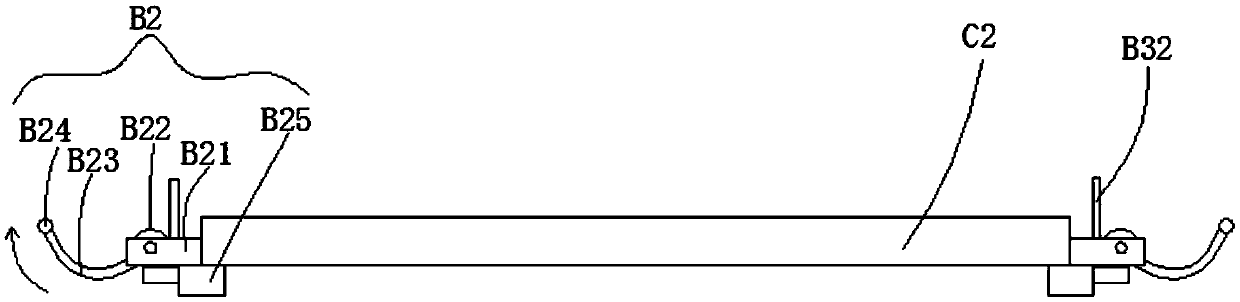

[0028] Such as figure 1 As shown, a plate moving mechanism of an edge sawing machine, the moving mechanism includes a first carrying platform C1, a second carrying platform C2 and a conveying mechanism C3 for the plate. The second carrying platform C2 moves forward or backward on the conveying mechanism C3; the second carrying platform C2 is located in the middle of the first carrying platform C1. The first carrying platform C1 moves up and down; the upper surface of the first carrying platform C1 when raised to the highest point is higher than the upper surface of the second carrying platform C2. When the first carrying platform C1 descends to the lowest point, the height of its upper surface is lower than the height of the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com