Shaping method for experimental grotto of earthquake simulated vibration platform model

A technology of model testing and forming methods, applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve problems such as inability to use models to form, and achieve the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0030] A method for forming an earthquake simulation shaking table model test cavity, comprising the following steps:

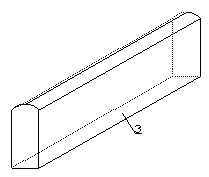

[0031] 1 Make the cavern solid model: Calculate the size of the cavern model in the model test according to the size of the real cavern in the actual project and the geometric similarity scale, and make a wooden mold with the same shape according to the calculated size of the cavern model, such as image 3 As shown, the molding density according to the mold size is 22Kg / m 3 The hardened and weighted polystyrene foam cavity model, remove the wooden mold after molding, and wrap a layer of polyvinyl chloride plastic with a thickness of 1mm on the surface of the model;

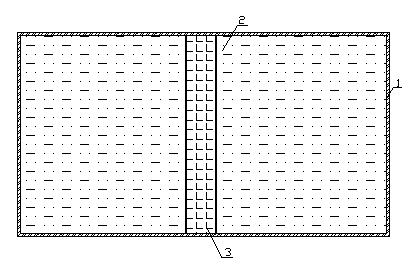

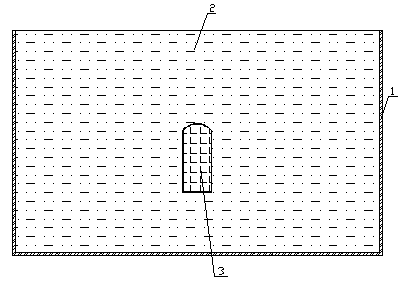

[0032] 2 Locate the cavern entity model: According to the position of the cavern model in the test design plan, use a ruler to determine the reserved position of the cavern on the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com