Antioxidative carbon aerogel material and preparation method thereof

A technology of carbon airgel and airgel, which is applied in the field of anti-oxidation carbon airgel materials and its preparation, can solve the problems of increased density and thermal conductivity, material weight gain, and clogging, so as to prevent clogging and improve anti-oxidation The effect of oxidation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

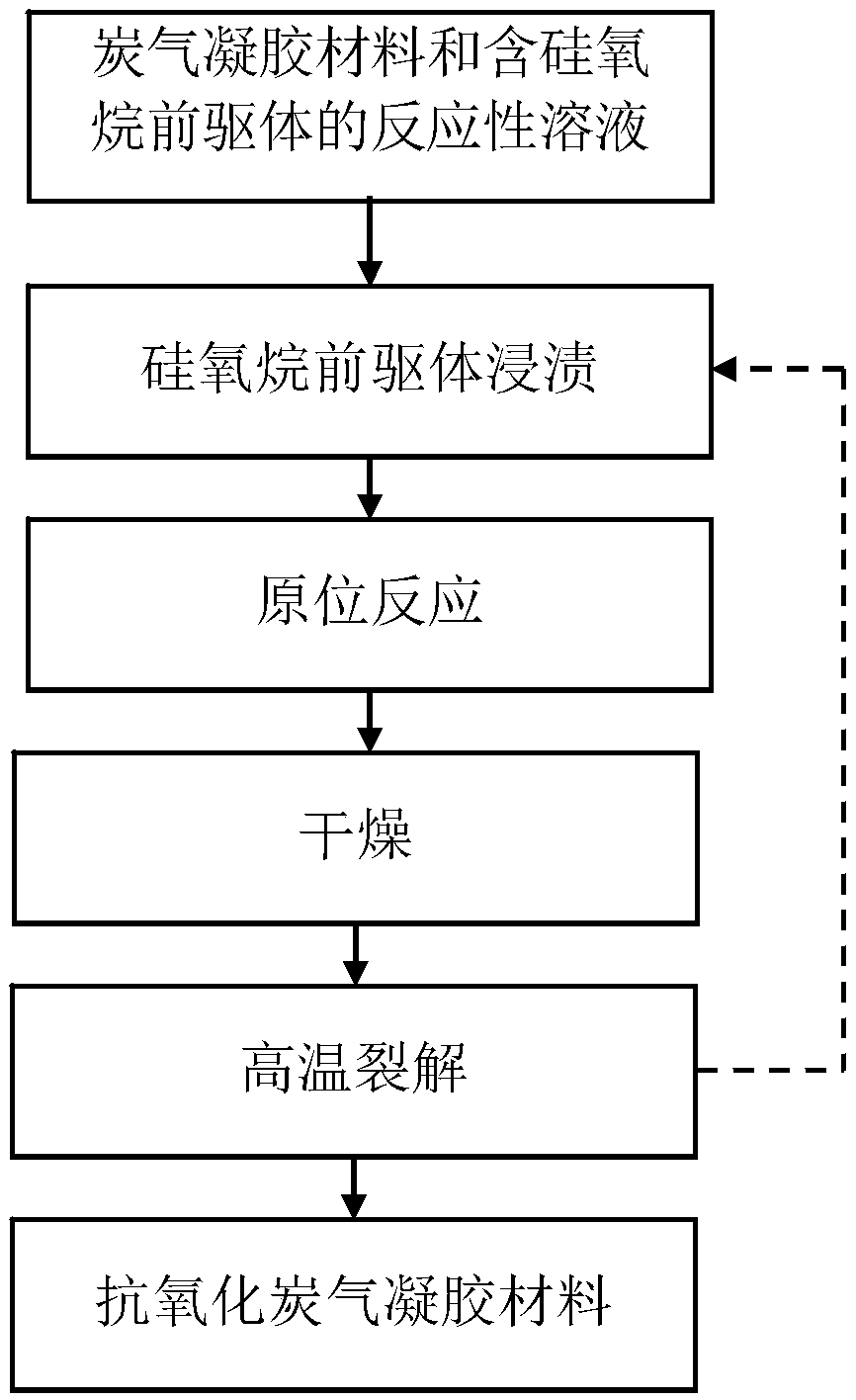

Method used

Image

Examples

Embodiment 1

[0059] This embodiment is carried out according to the following steps:

[0060] (1) Prepare the reactive solution of siloxane precursor

[0061] Dissolve trimethylmethoxysilane and dimethyldimethoxysilane in ethanol to prepare a uniform solution, then add 1mol / L nitric acid aqueous solution as a catalyst, trimethylmethoxysilane: dimethyldimethoxysilane Methoxysilane: nitric acid solution: ethanol = 20:4:3:53 (wt%).

[0062] (2) Vacuum impregnated carbon airgel material

[0063] Within 1 hour of completing the preparation of the above reactive solution, take a density of 0.45g / cm 3 The carbon airgel material, the reactive solution is injected into the carbon airgel material by vacuum impregnation. First, put the carbon airgel material into a sealable mold with a glue inlet and a glue outlet, tighten the screws to seal the system, close the glue inlet, open the glue outlet, and evacuate to -0.095MPa. Open the inlet to draw the reactive solution into the mold. Then close th...

Embodiment 2~13

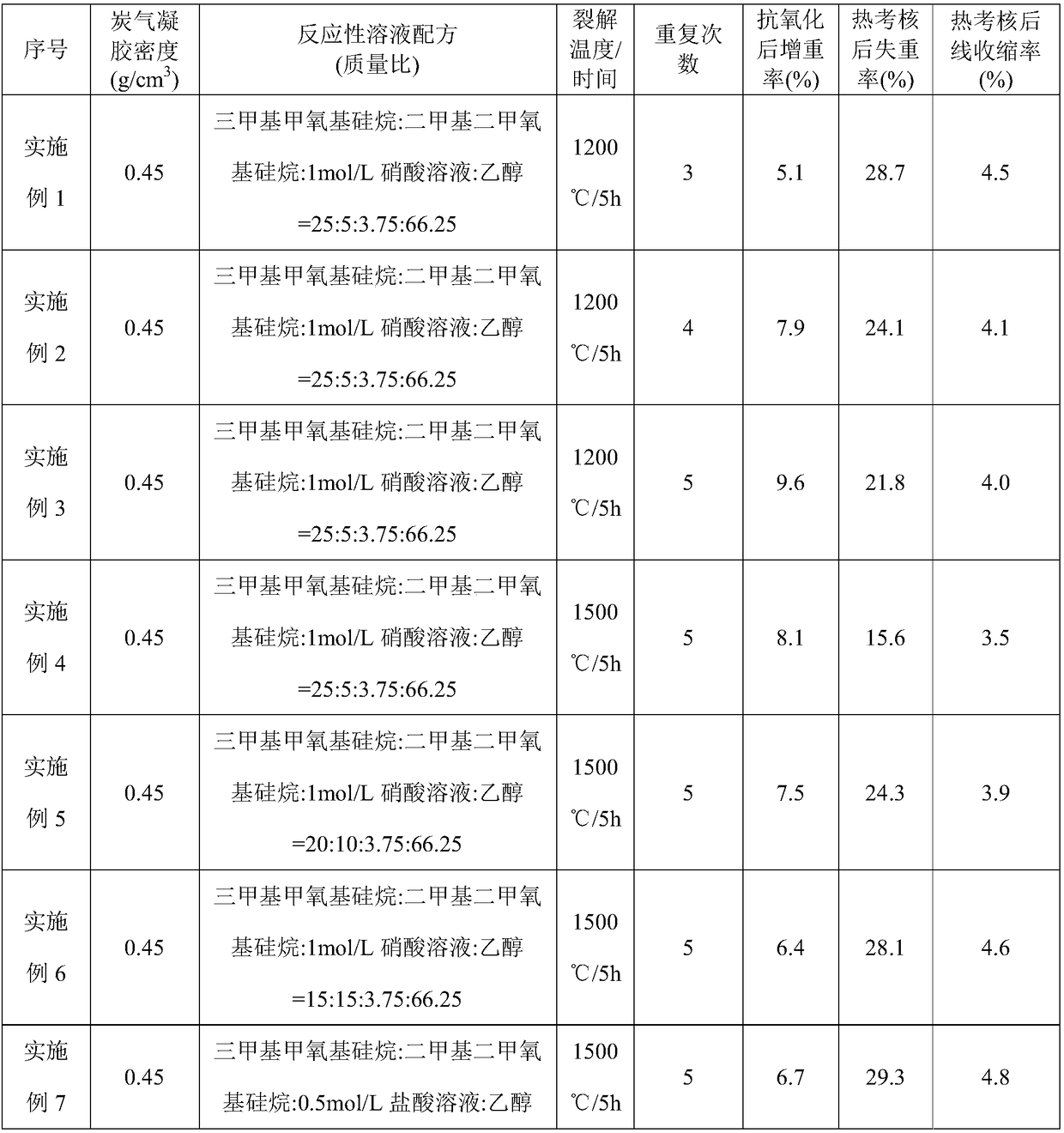

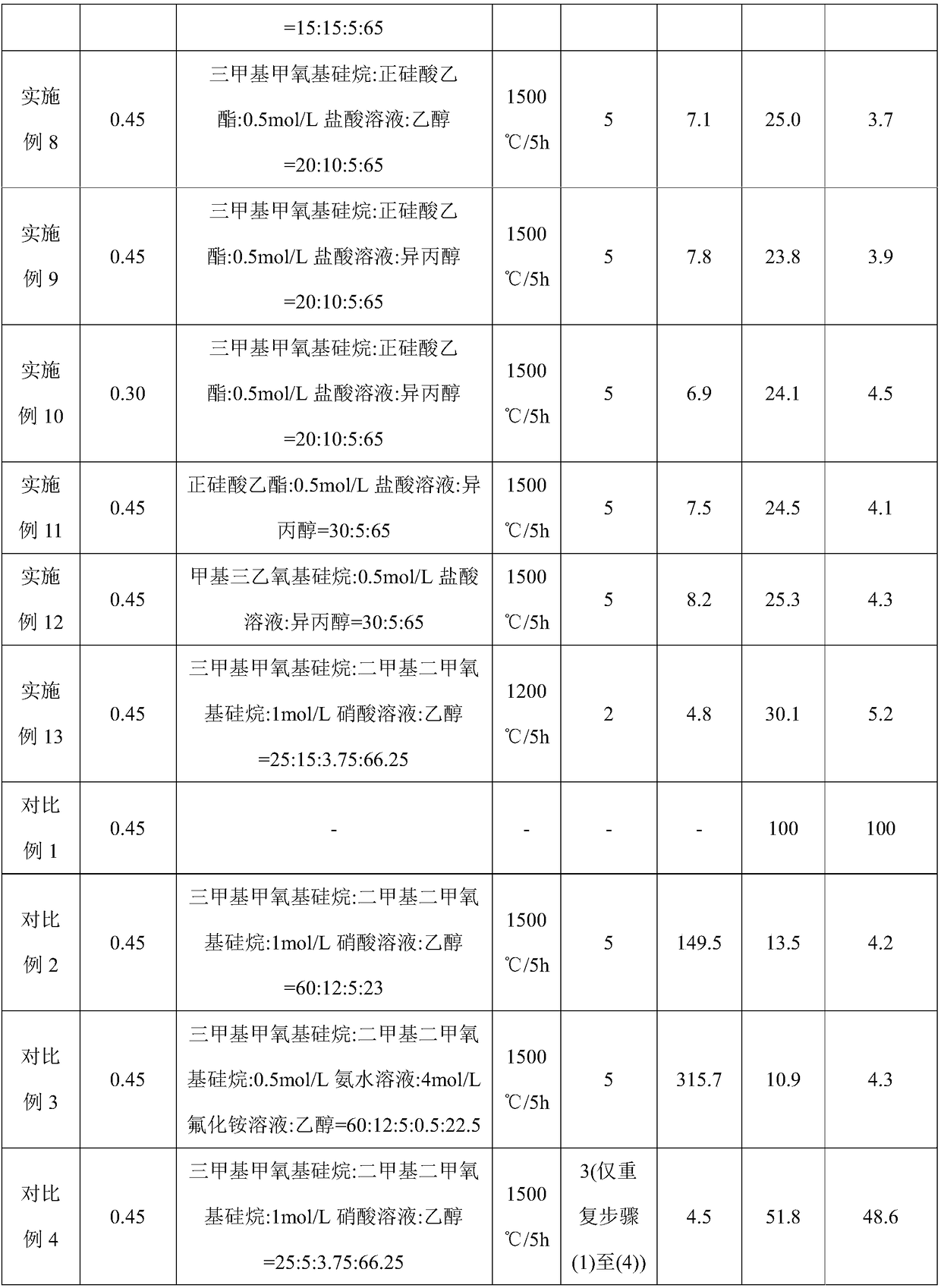

[0074] The process parameters adopted in Examples 2 to 13 are shown in Table 1. Except for the listed parameters, the remaining unmentioned process parameters are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com