Investment casting wax based on graphite oxide modified rosin and preparation method thereof

A graphite modification and precision casting technology, applied in casting molding equipment, chemical modification of natural resins, etc., can solve the problems of poor process performance, increased viscosity of mold materials, unfavorable occupational health, etc. Small shrinkage and improved synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

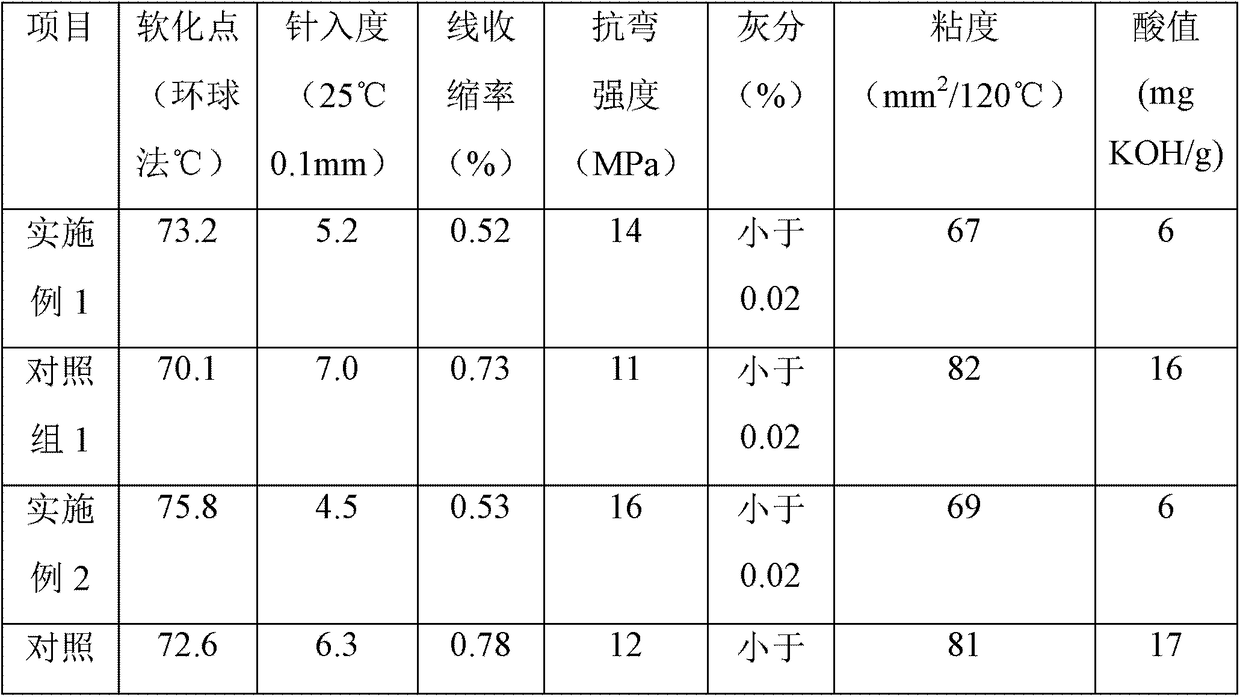

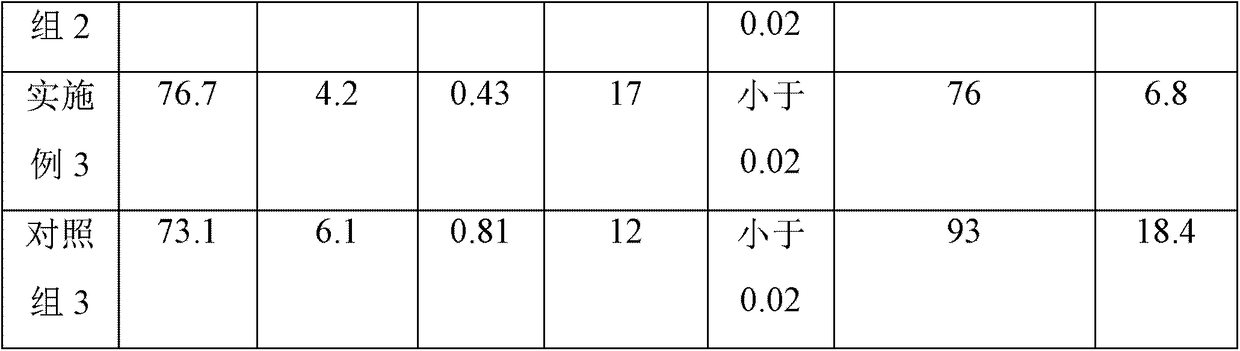

Embodiment 1

[0027] Add 100g first-grade rosin (Jiangxi masson pine, softening point 82°C) to a volume of 1 liter autoclave, dissolve at 120°C, add catalyst graphite oxide 5g (quality 5% of rosin) (Hubei Yihua Chemical Industry Co., Ltd. Co., Ltd.), promoter zinc oxide 3g (0.3% of the mass of rosin) (Nanhua brand), 5g of pentaerythritol (5% of the mass of rosin) (Hubei Yihua Chemical Co., Ltd.), stirring and melting, airtight, continue to heat to 280 ° C , control the system temperature not to exceed 290°C, react for 3 hours, the catalyst zinc oxide and graphite oxide in the system, and the remaining pentaerythritol do not need to be separated to obtain a modified rosin resin mixture, degas and reduce the temperature of the system to 140°C Add C5 petroleum resin 40g (8%) (YH-1288, Henghe Material Technology Co., Ltd.), PE wax 25g (5%) (Thailand SCG chemical / LP0500F polyethylene wax, 115 ℃) and montan wax 10g ( 2%) (Shangcheng brand, Yunnan), melt completely, continue stirring for 30 minute...

Embodiment 2

[0031] Add 100g first-grade rosin (Jiangxi masson pine, softening point 82°C) to a volume of 1 liter autoclave, dissolve at 120°C, add catalyst graphite oxide 8g (quality 5% of rosin) (Hubei Yihua Chemical Industry Co., Ltd. Co., Ltd.), promoter zinc oxide 3g (0.3% of the mass of rosin) (Nanhua brand), 5g of pentaerythritol (5% of the mass of rosin) (Hubei Yihua Chemical Co., Ltd.), stirring and melting, airtight, continue to heat to 280 ° C , control the system temperature not to exceed 290°C, react for 3 hours, the catalyst zinc oxide and graphite oxide in the system, and the remaining pentaerythritol do not need to be separated to obtain a modified rosin resin mixture, degas and reduce the temperature of the system to 140°C About, add terpene resin 40g (8%) (T100, Shenzhen Yoshida Chemical), PE wax 25g (5%) (Thailand SCG Chemical / LP0500F polyethylene wax, 115 ℃) and montan wax 10g (2%) (still was brand, Yunnan), completely melted, and after continuing to stir for 30 minutes...

Embodiment 3

[0035] Add 125g first-grade rosin (Jiangxi masson pine, softening point 82°C) to a volume of 1 liter autoclave, dissolve at 120°C, add catalyst oxide graphite 6.25g (quality 5% of rosin) (Hubei Yihua Chemical Industry Co., Ltd. Co., Ltd.), promoter zinc oxide 3.75g (0.3% of the mass of rosin) (Nanhua brand), 6.25g of pentaerythritol (5% of the mass of rosin) (Hubei Yihua Chemical Co., Ltd.), stirring and melting, airtight, and continued heating to 280°C, the temperature of the control system must not exceed 290°C, react for 3 hours, the catalyst zinc oxide and graphite oxide in the system, and the remaining pentaerythritol do not need to be separated to obtain a modified rosin resin mixture, deflate and reduce the temperature of the system To about 140°C, add terpene resin 40g (8%) (T100, Shenzhen Yoshida Chemical), PE wax 25g (7%) (Thailand SCG Chemical / LP0500F polyethylene wax, 115°C) and montan wax 10g (2%) (Shangcheng brand, Yunnan), completely melted, continue to stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com