Method for low-temperature firing of ceramic brick by using high-calcium fly ash

A technology of high-calcium fly ash and ceramic bricks, which is applied in the production, application, and household appliances of ceramic materials. The effect of billet pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

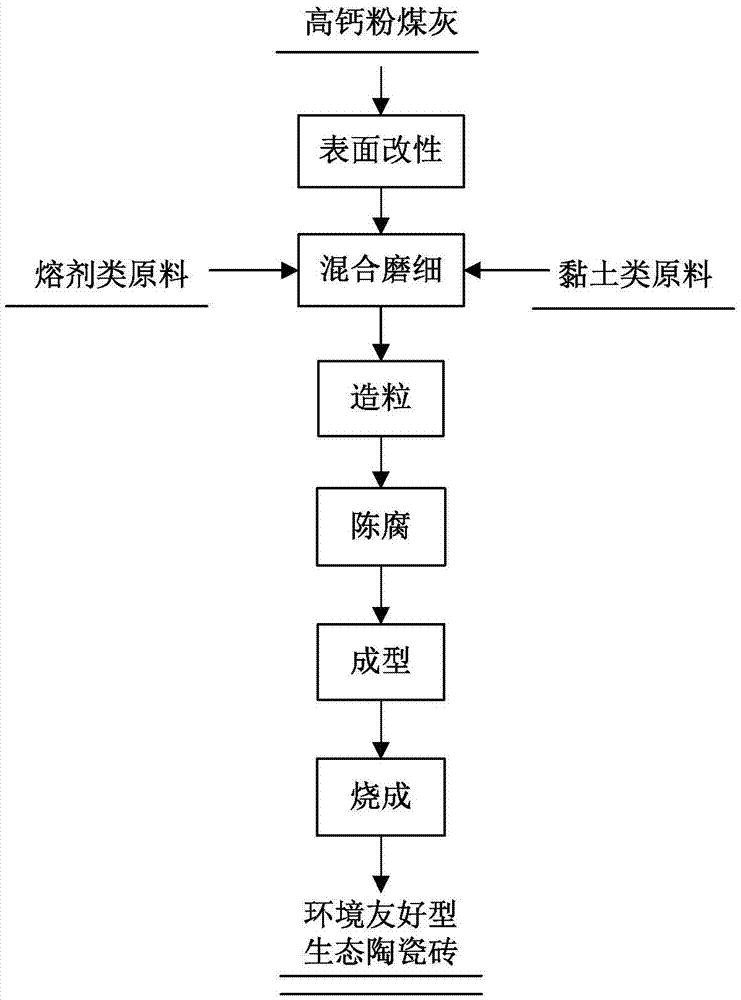

[0032] This example uses high-calcium fly ash from a thermal power plant in Xilin Gol League, Inner Mongolia, whose main component is 42.25% SiO 2 , 14.94% Al 2 o 3 , 5.35% CaO and 10.11% Fe 2 o 3 . Production basis of high-calcium fly ash-based environmentally friendly ecological ceramic bricks figure 1 process flow. Firstly, the surface modification pretreatment of high-calcium fly ash was carried out. The high-calcium fly ash was added to 80g / L NaOH solution system, the reaction temperature was 90°C, the liquid-solid ratio was 4, and the reaction time was 1h. Filter and wash the slurry to obtain surface-modified high-calcium fly ash mixed with bentonite, talc, diopside, and heavy calcium carbonate in proportions of 50%, 25%, 20%, 4%, and 1%. Add 35% (35% of the total mass of the slurry after ball milling) water and 0.3% sodium tripolyphosphate (0.3% of the mass of the dry material), and ball mill until it becomes a uniform slurry (after the ball milling, the slurry pa...

Embodiment 2

[0034] This example uses high-calcium fly ash from a thermal power plant in Xilin Gol League, Inner Mongolia, whose main component is 51.45% SiO 2 , 22.30% Al 2 o 3 , 6.63% CaO and 4.47% Fe 2 o 3 . Production basis of high-calcium fly ash-based environmentally friendly ecological ceramic bricks figure 1 process flow. Firstly, the surface modification pretreatment of high-calcium fly ash was carried out. The high-calcium fly ash was added to 90g / L NaOH solution system, the reaction temperature was 100°C, the liquid-solid ratio was 6, and the reaction time was 2h. Filtrate and wash the slurry to obtain surface-modified high-calcium fly ash mixed with pyrophyllite, diopside, bentonite, and heavy calcium carbonate in proportions of 40%, 20%, 24%, 15%, and 1%. Add 48% (48% of the total mass of the slurry after ball milling) water and 0.8% sodium silicate (0.8% of the dry material mass), and ball mill until it becomes a uniform slurry (after the ball milling, the slurry passes...

Embodiment 3

[0036] This example uses high-calcium fly ash from a thermal power plant in Xilin Gol League, Inner Mongolia, whose main component is 55.57% SiO 2 , 21.47% Al 2 o 3 , 5.12% CaO and 6.80% Fe 2 o 3 . Production basis of high-calcium fly ash-based environmentally friendly ecological ceramic bricks figure 1process flow. Firstly, the surface modification pretreatment of high-calcium fly ash was carried out. The high-calcium fly ash was added to a 150g / L NaOH solution system. The reaction temperature was 80°C, the liquid-solid ratio was 3, and the reaction time was 0.5h. The slurry is filtered and washed to obtain the surface-modified high-calcium fly ash and kaolin, potassium feldspar, and pyrophyllite according to the ratio of 40%, 23%, 20%, and 17%, and add 40% (the total amount of slurry after ball milling 40% of the mass) of water and 1% sodium humate (1% of the dry material mass), ball milled to a homogeneous slurry (the slurry after the ball mill passes through a 250 me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com