Filling type investment casting pattern material with high filler content and preparation method of filling type investment casting pattern material

An investment casting and filler technology, applied in casting and molding equipment and other directions, can solve problems such as filler content not exceeding 30%, mold material not meeting the requirements, reducing linear shrinkage, etc., to achieve good fluidity, moderate viscosity, line Small shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

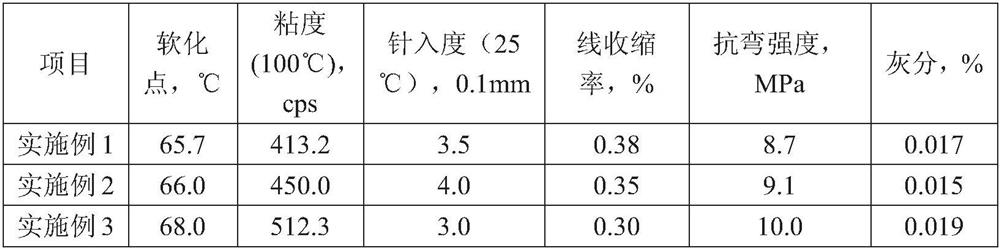

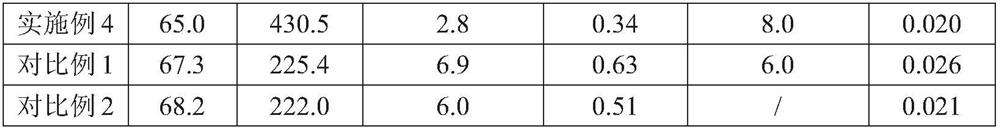

Examples

Embodiment 1

[0031] A filled investment casting mold material with high filler content, which contains the following raw materials in parts by weight: 30 parts of 62# fully refined paraffin wax, 30 parts of C5 hydrogenated petroleum resin, 5 parts of beeswax, 4 parts of ethylene-vinyl acetate Parts, 30 parts of α-methyl styrene powder, 1 part of polyethylene glycol stearate.

[0032] The preparation method of the above-mentioned filled investment casting mold material with high filler content comprises the following steps:

[0033] (1), heating and stirring the 62# fully refined paraffin wax, C5 hydrogenated petroleum resin, and beeswax at a temperature of 100°C-120°C to form a uniform and transparent liquid mixture A;

[0034] (2) Add the above-mentioned liquid mixture A with the ethylene-vinyl acetate in the weight fraction, control the temperature: 120°C-130°C, keep stirring until it melts into a uniform and transparent liquid mixture B, and use a 200-mesh filter filter;

[0035] (3) ...

Embodiment 2

[0037] A filling type investment casting mold material with high filler content, which contains the following raw materials in parts by weight: 15 parts of 64# fully refined paraffin wax, 15 parts of 80# microcrystalline wax, 20 parts of terpene resin T-100, small 6 parts of candelabra wax, 1 part of APAO, 40 parts of cyclohexamethylenetetramine, 3 parts of monoglyceride stearate.

[0038] The preparation method of the above-mentioned filled investment casting mold material with high filler content comprises the following steps:

[0039] (1) 64# fully refined paraffin wax, 80# microcrystalline wax, terpene resin, and candelilla wax are heated and stirred at a temperature of 100°C-120°C to melt into a uniform and transparent liquid mixture A;

[0040] (2) Add the above-mentioned liquid mixture A into the APAO by weight fraction, control the temperature: 120°C-130°C, stir continuously until it melts into a uniform and transparent liquid mixture B, and filter it with a 200-mesh f...

Embodiment 3

[0043]A filled investment casting mold material with high filler content, which contains the following raw materials in parts by weight: 13.5 parts of 60# fully refined paraffin wax, 10 parts of 85# microcrystalline wax, 15 parts of C5 / C9 copolymerized petroleum resin, Brazil 8 parts of palm wax, 0.5 parts of ethylene-acrylic acid copolymer, 45 parts of cellulose acetate powder, and 8 parts of polyoxyethylene sorbitan fatty acid ester.

[0044] The preparation method of the above-mentioned filled investment casting mold material with high filler content comprises the following steps:

[0045] (1), 60# fully refined paraffin wax, 85# microcrystalline wax, C5 / C9 copolymerized petroleum resin, and carnauba wax are heated and stirred at a temperature of 100°C-120°C to melt into a uniform and transparent liquid mixture A ;

[0046] (2) Add the ethylene-acrylic acid copolymer in the above-mentioned liquid mixture A, control the temperature: 120°C-130°C, stir continuously until it m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com