Silica gel gutta-percha and manufacturing technology thereof

A manufacturing process, silica gel technology, applied in the field of silica gel teether and its manufacturing process, can solve the problems of liquid entering the baby's body, damaging the baby's health, and the product cannot be used, etc., to achieve the effect of softness, non-breakability, and low linear shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

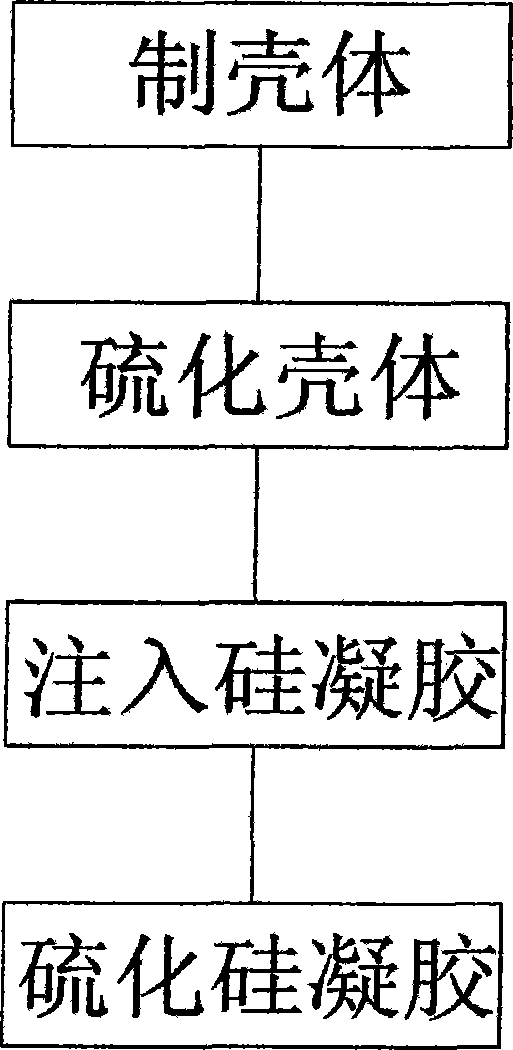

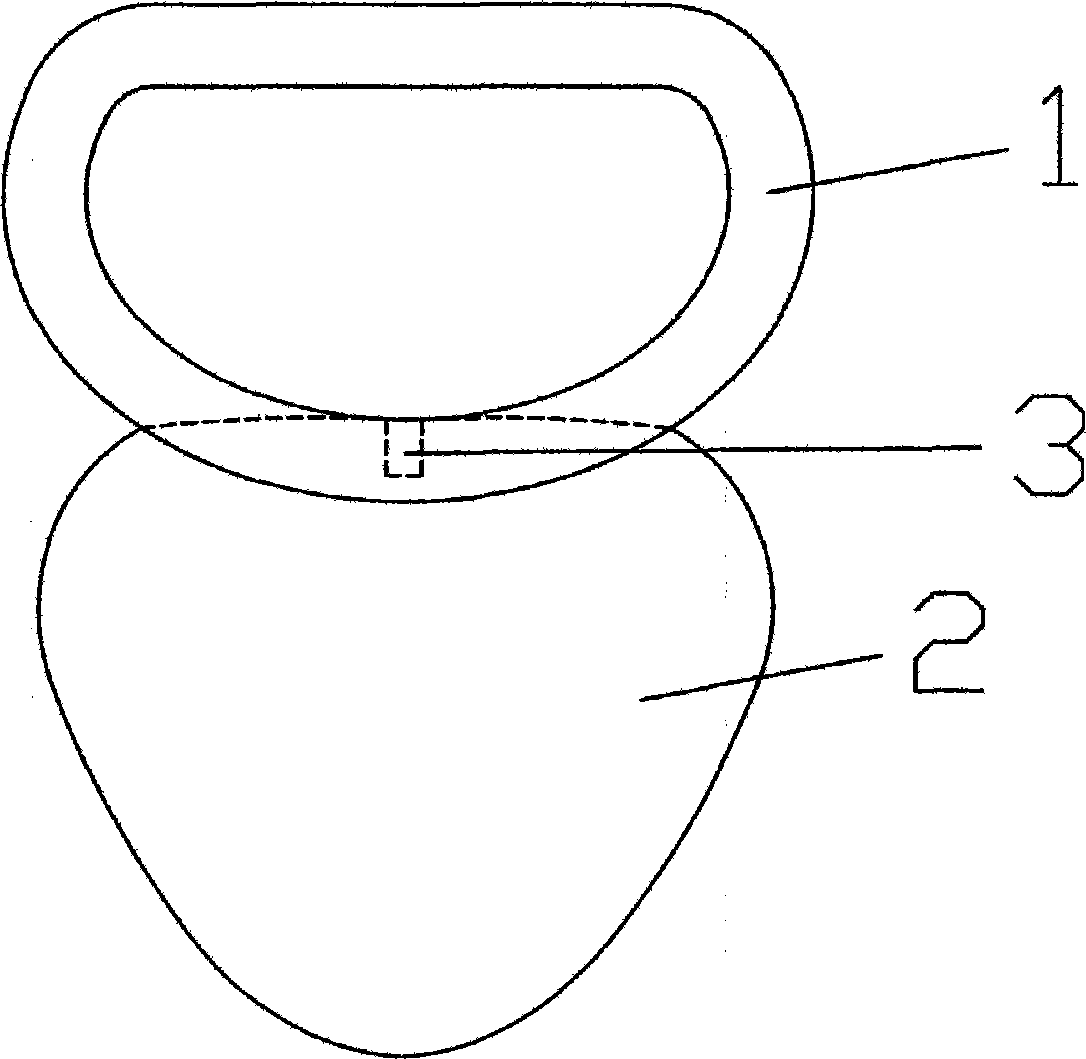

[0026] Such as figure 1 As shown in the manufacturing process of the silicone gutta-percha, the silicone material is poured into the mold to form the silicone shell 1 with the injection port 3, and then the silicone shell 1 is vulcanized at an ambient temperature of 70°C-90°C. Remake the silicone gel:

[0027] a) Measurement: Accurate weighing of components A and B should comply with A:B=1:1 (weight);

[0028] b) Rubber mixing: fully and evenly mix components A and B;

[0029] c) defoaming: place the uniformly mixed glue in a vacuum container for defoaming;

[0030] d) Pouring: pour the glue that has been debubbled into the silicone shell 1 through the injection port 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com