Coupling device for connecting rotating body

A technology of rotating bodies and couplings, applied in the direction of couplings, elastic couplings, rigid shaft couplings, etc., can solve problems such as axial deviation, and achieve the effect of long-term aging resistance improvement and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

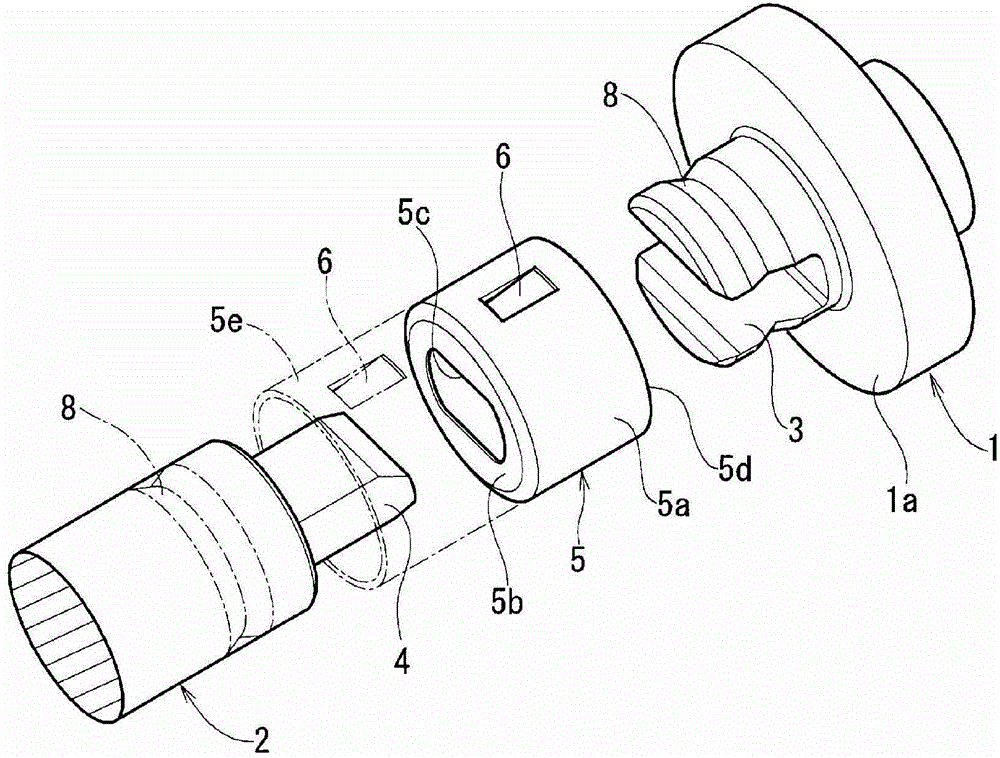

[0055] Below, combined with the accompanying drawings Figure 3 ~ Figure 18 Embodiments of the joint device for connecting rotating bodies of the present invention will be described.

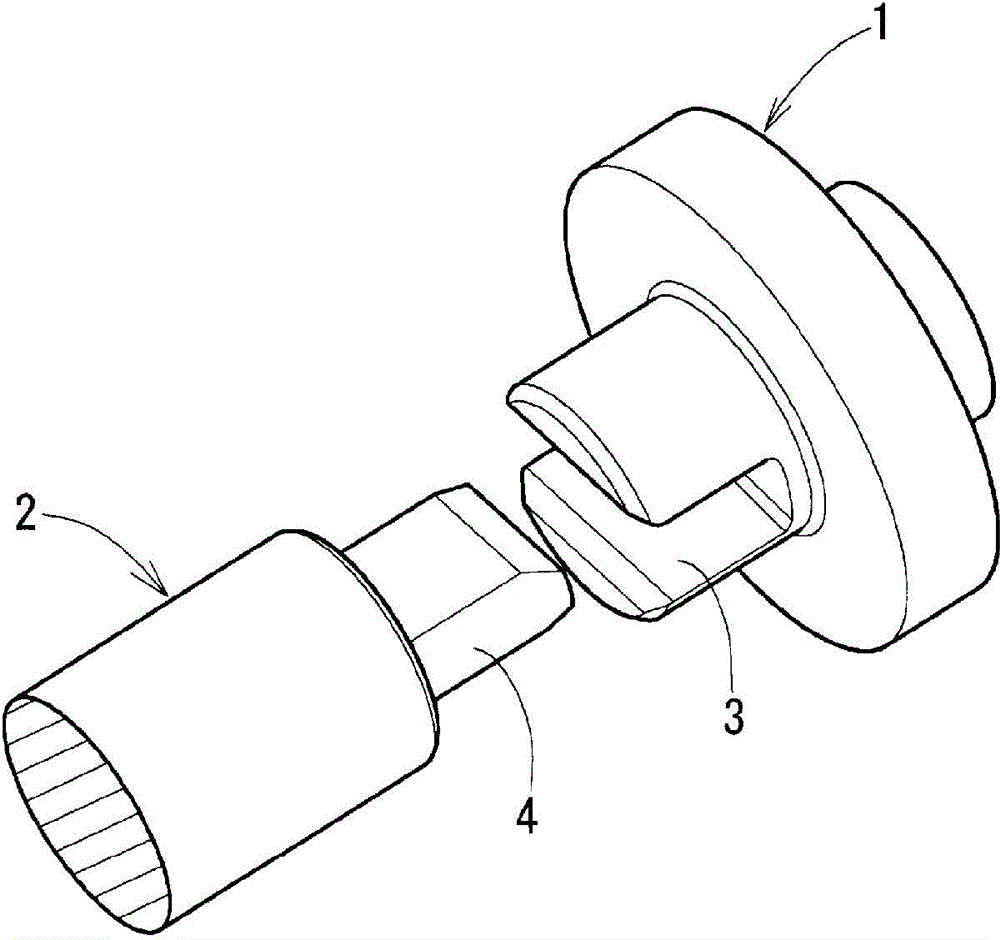

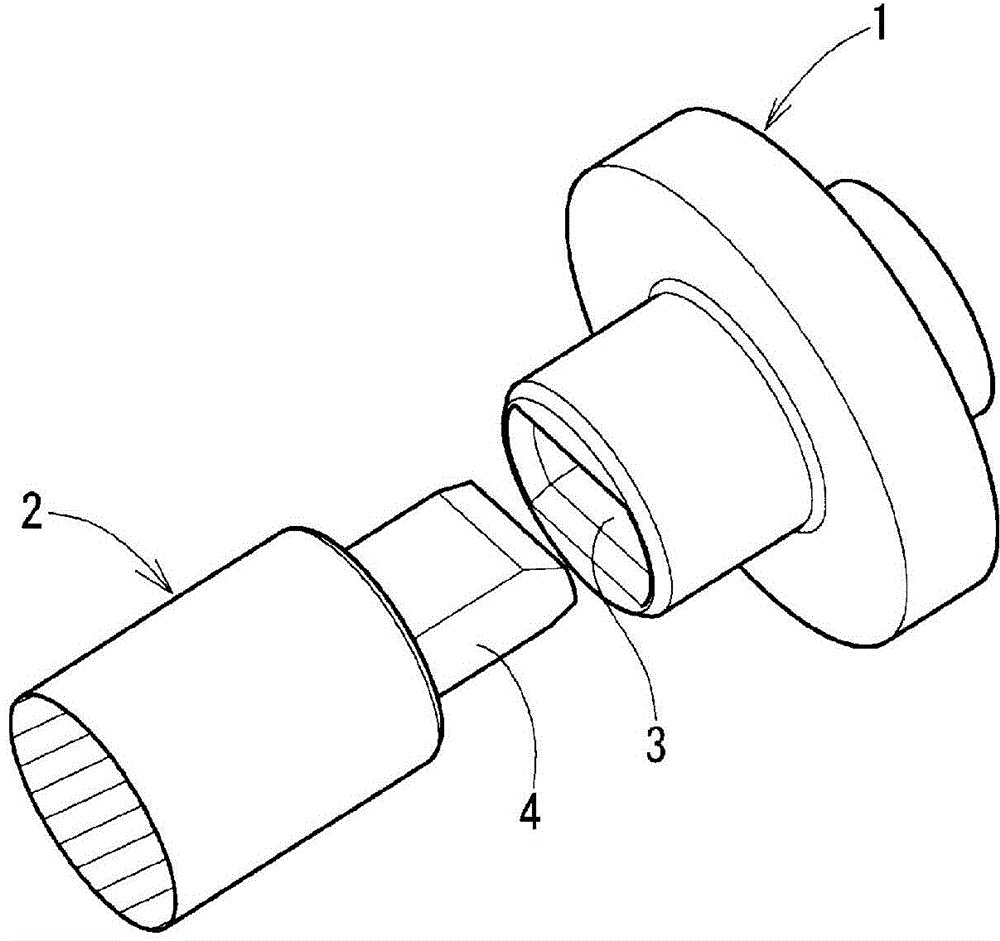

[0056] First of all, the basic mode of applying the shaft coupling device of the present invention is as follows: figure 1 as well as figure 2 shown. figure 1 It is a coupling device in which the sliding surface of the connecting part is opened on the outer periphery of the connecting part. figure 2 It is a joint device in which the sliding surface of the connecting part is not opened on the outer circumference of the connecting part. If the present invention is applied to figure 1 The open coupling device can be expected to get a particularly large effect, while in figure 2 It is also effective in non-open coupling devices.

[0057] These coupling devices are connected so that the first rotating body 1 and the second rotating body 2 face each other on the same axis and allow radial rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com