Liquid Level Measurement and Control System for Aircraft Test

A liquid level measurement and control system technology, which is applied in liquid level control, control/regulation system, aircraft component testing, etc., can solve the problems that the low-temperature brine can’t be evacuated and filled, and achieve a smooth and efficient experiment process. Strong practicability and the effect of preventing local accumulation of fluid or gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

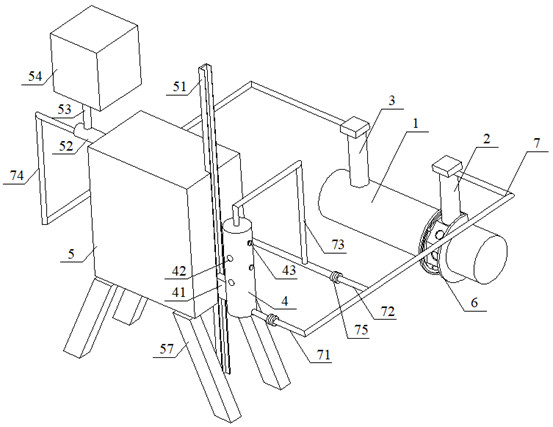

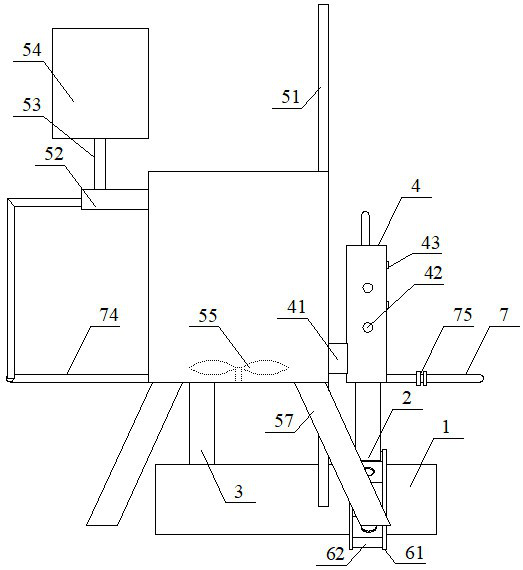

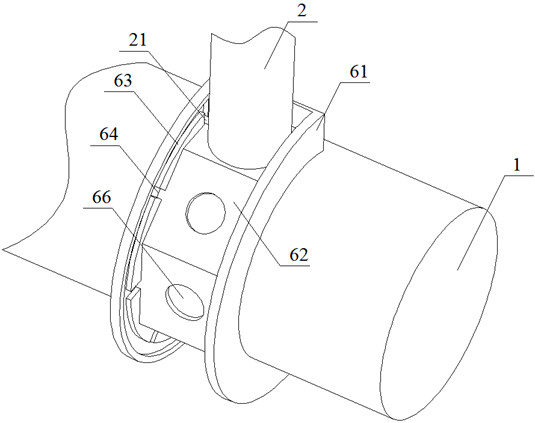

[0032] Such as figure 1 As shown, an aircraft test liquid level measurement and control system includes a liquid outlet pipe 2 and a liquid return pipe 3 installed on the pipeline 1 to be tested, a sight liquid barrel 4 communicated with the liquid outlet pipe 2, and a liquid sight barrel 4 connected to the liquid sight barrel. 4 The effusion bag 5 communicated with each other, the effusion bag 5 is connected with the liquid return pipe 3, the liquid outlet pipe 2 is connected with the pipeline 1 to be tested through a group of adjustment mechanisms 6 for adjusting its angle and position, and the liquid outlet pipe 2 The end is provided with a group of hoses 7, the ends of the hoses 7 are bifurcated into a first hose 71 and a second hose 72, the first hose 71 is connected to the bottom of the liquid sight barrel 4, and the second hose 72 is connected to the effusion bag 5 Bottom connection, the first hose 71 and the second hose 72 are provided with a valve 75, and the top of t...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that there are 6 sets of fixing blocks 62 .

Embodiment 3

[0039] The difference between this embodiment and Embodiment 1 is that there are 7 sets of fixing blocks 62 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com