Method for preparing silicon dioxide aerogel by sublimation method

A technology of silica and airgel, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of cumbersome preparation process and long cycle, and achieve enhanced network structure, reduced capillary force, and reduced shrinkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

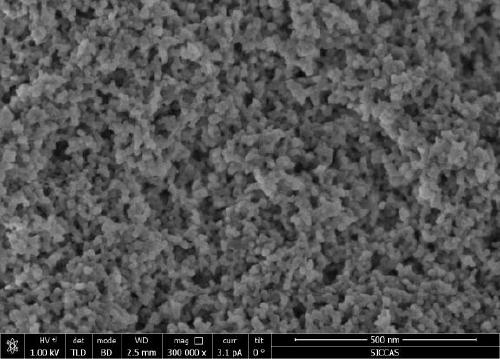

[0028] Dissolve naphthalene in methanol water solvent and stir to obtain a transparent solution, add tetramethyl orthosilicate and ammonia water to the above solution and stir evenly, and let stand to obtain a gel; age the gel at 60°C for 12 h, and then in 10 Carry out vacuum sublimation at ℃ to remove naphthalene in the gel pores to obtain silica airgel; wherein the molar ratio of naphthalene, tetramethylorthosilicate, methanol, water, and ammonia is 1: 0.1:10:0.4:0.001;

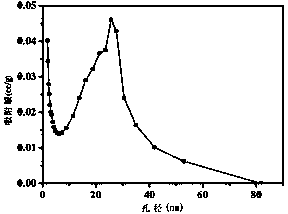

[0029] The prepared silica airgel has a density of 0.05 g cm -3 The pore size distribution measured by nitrogen adsorption method is 1~200nm, and the BET specific surface area is as high as 1000 m 2 g -1 , the thermal conductivity measured by the planar heat source method is 0.01 W·m -1 k -1 .

Embodiment 2

[0031] Dissolve naphthalene in ethanol water solvent and stir to obtain a transparent solution, add tetraethylorthosilicate and ammonia water to the above solution and stir evenly, and let it stand to obtain a gel; aging the gel at 80°C for 2 h, and then at 40 Carry out vacuum sublimation at ℃ to remove naphthalene in the gel pores to obtain silica airgel; wherein the molar ratio of naphthalene, tetramethylorthosilicate, ethanol, water, and ammonia is 1: 20:10:10:0.05;

[0032] The prepared silica airgel has a density of 0.65 g cm -3 , the pore size distribution measured by nitrogen adsorption method is 2~80 nm, and the BET specific surface area is as high as 300 m 2 g -1 , the thermal conductivity measured by the planar heat source method is 0.08 W·m -1 k -1 .

Embodiment 3

[0034] Dissolve benzoic acid in ethanol water solvent and stir to obtain a transparent solution, add polysiloxane and urea to the above solution, stir evenly, and let stand to obtain a gel; age the gel at 80°C for 4 h, and then in 30 Carry out vacuum sublimation at ℃ to remove benzoic acid in the pores of the gel to obtain silica airgel; the molar ratio of benzoic acid, polysiloxane, ethanol, water, and urea is 1: 10:50:2:0.02 ;

[0035] The prepared silica airgel has a density of 0.15 g cm -3 , the pore size distribution measured by nitrogen adsorption method is 2~100nm, and the BET specific surface area is as high as 620 m 2 g -1 , the thermal conductivity measured by the planar heat source method is 0.025 W·m -1 k -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com