Preparation method of zirconium oxide aerogel

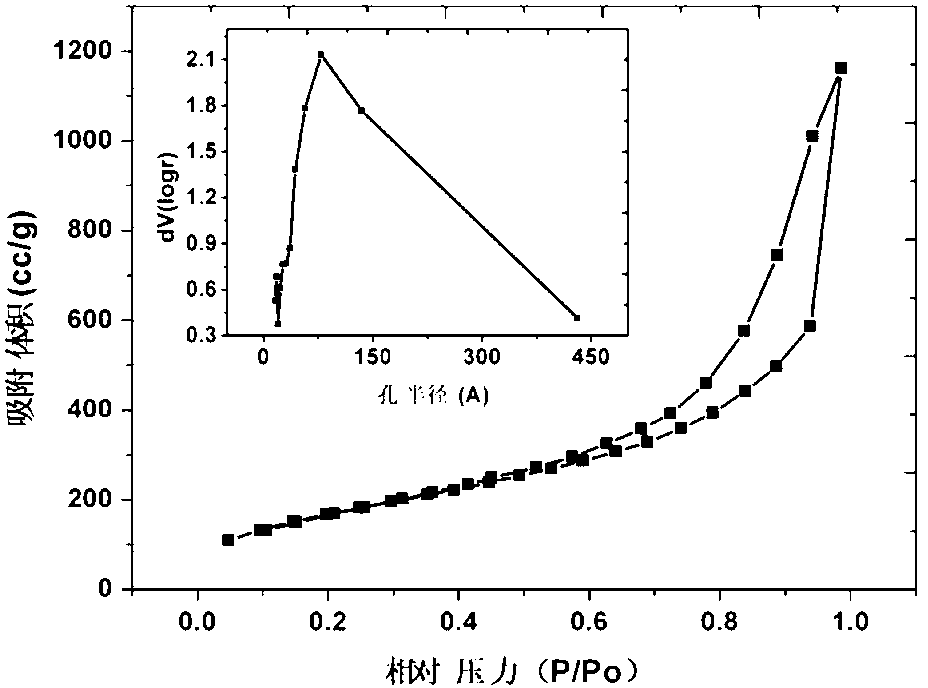

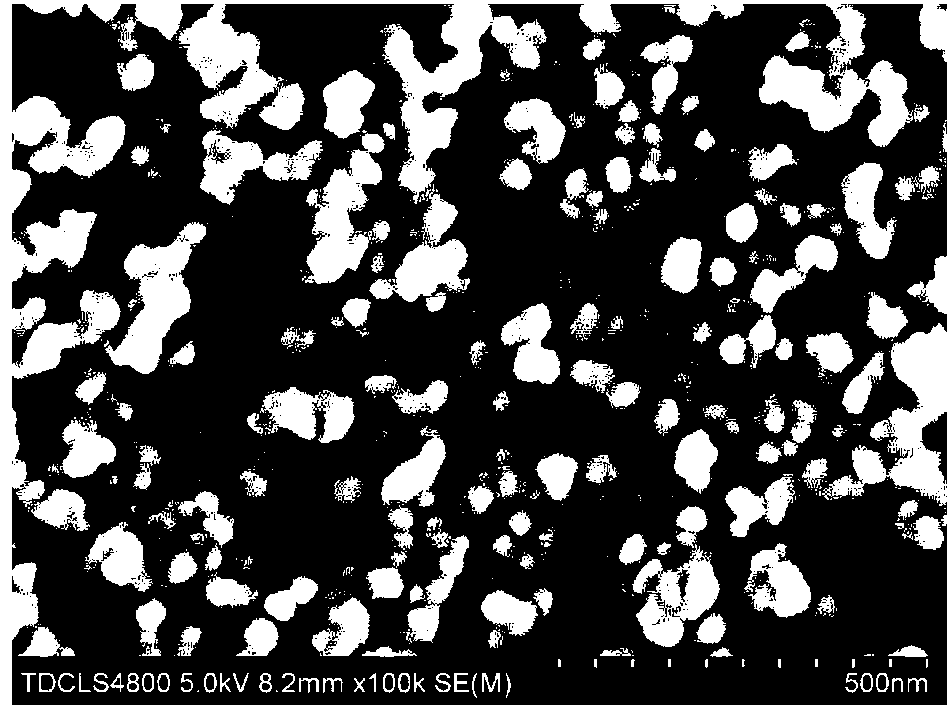

A technology of airgel and zirconia, which is applied in the direction of zirconia to achieve the effect of reducing the possibility of cracking, reducing stress and increasing continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] a ZrO 2 The preparation method of the airgel, the zirconium alkoxide is selected from zirconium n-butoxide, the epoxy is selected from propylene oxide, and the aging solution is absolute ethanol: tetraethyl orthosilicate: propylene oxide = 5:2:2 (volume ratio) The mixed solution, the low surface tension solvent is absolute ethanol. Follow the steps in order:

[0031] 1) ZrO 2 Preparation of sol: at 4°C, dissolve zirconium n-butoxide in absolute ethanol and mix uniformly to obtain a 0.25mol / L ethanol solution of zirconium n-butoxide; then follow the steps of zirconium n-butoxide: water: nitric acid: formamide: ring Propylene oxide=1:6:1:0:6 (molar ratio) Add 65-68wt% concentrated nitric acid drop by drop, continue to stir for 5 minutes; add water and propylene oxide, continue to stir for 30 minutes to obtain a light yellow transparent sol.

[0032] 2) ZrO 2 Preparation of wet gel: after the above sol stops stirring, transfer the sol to a mold and let it stand for 4 h...

Embodiment 2

[0038] a ZrO 2 The preparation method of the airgel, the zirconium alkoxide is selected from zirconium n-propoxide, the drying control agent is formamide, the epoxide is propylene oxide, and the aging solution is absolute ethanol: tetraethyl orthosilicate: propylene oxide=5: 4: 0.5 (volume ratio) the mixed solution after stirring, the low surface tension solvent is isopropanol. Follow the steps in order:

[0039] 1) ZrO 2 Preparation of sol: Dissolve zirconium n-propoxide in ethanol at 15°C, stir and mix evenly to obtain a 0.5mol / L ethanol solution of zirconium n-propoxide; then follow the steps of zirconium n-butoxide: water: nitric acid: formamide: ring Propylene oxide=1:2:0.856:0.3:3 (molar ratio) Add 65-68wt% concentrated nitric acid drop by drop, continue to stir for 20 minutes; add water, formamide and propylene oxide, continue to stir for 60 minutes to obtain a light yellow transparent sol ;

[0040] 2) ZrO 2 Preparation of wet gel: After stopping the stirring of t...

Embodiment 3

[0046] a ZrO 2 The preparation method of the airgel, the zirconium alkoxide is selected from zirconium isopropoxide, the drying control agent is formamide, and the aging solution is anhydrous ethanol: ethyl orthosilicate: propylene oxide = 5:3:1 (volume ratio) stirring After the mixed solution; the low surface tension solvent is absolute ethanol. Follow the steps in order:

[0047] 1) ZrO 2 Preparation of sol: Dissolve zirconium isopropoxide in ethanol at 40°C, stir and mix evenly to obtain a 2mol / L ethanol solution of zirconium isopropoxide; then follow the steps of zirconium isopropoxide: water: nitric acid: formamide: epoxy Propane=1:2:0.7:2:0 (molar ratio) Add 65-68wt% concentrated nitric acid drop by drop, continue to stir for 60 minutes; add water and formamide, continue to stir for 20 minutes to obtain light yellow transparent sol;

[0048] 2) ZrO 2 Preparation of the wet gel: after the stirring of the above sol was stopped, the sol was transferred to a mold, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com