Preparation method of high-temperature-resistant ultralow-density silicon carbide nanotube aerogel

A density silicon carbide and airgel technology, applied in the direction of airgel preparation, chemical instruments and methods, carbon compounds, etc., can solve the problem of high gel density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve methyltrimethoxysilane, dimethyldimethoxysilane and cetyltrimethylammonium bromide in deionized water to obtain a transparent solution, in which methyltrimethoxysilane, dimethyldimethoxy The mol ratio of base silane, cetyltrimethylammonium bromide, deionized water is 1:0.1: 0.1: 80; Add 2 mol / L ammoniacal liquor in above-mentioned solution and regulate solution pH and be 9.0 and form gel, will The gel was soaked in absolute ethanol three times, each time for 12 h; the soaked gel was directly put into an oven for drying under normal pressure at 80 °C for 48 h to obtain polyalkylsiloxane airgel. The average pore diameter of the prepared polyalkylsiloxane airgel is 2200 nm.

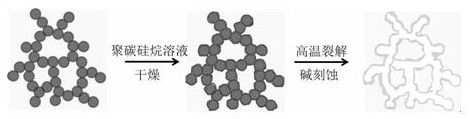

[0029] Immerse the polyalkylsiloxane airgel in a xylene solution containing 1% polycarbosilane until the solution completely wets the gel, and dry the wetted polyalkylsiloxane airgel in vacuum ( The vacuum degree is less than 20Pa, and the drying temperature is 30°C) to obtain the polyalkyls...

Embodiment 2

[0032] Dissolve methyltrimethoxysilane, dimethyldimethoxysilane and cetyltrimethylammonium bromide in deionized water to obtain a transparent solution, in which methyltrimethoxysilane, dimethyldimethoxy The mol ratio of base silane, cetyltrimethylammonium bromide, deionized water is 1:0.2: 0.2: 60; Add 3 mol / L ammoniacal liquor in above-mentioned solution and regulate solution pH value and be 10.0 and form gel, will The gel was soaked in absolute ethanol three times, each time for 12 h; the soaked gel was directly put into an oven for drying under normal pressure at 100 °C for 48 h to obtain polyalkylsiloxane airgel. The average pore diameter of the prepared polyalkylsiloxane airgel was 1200 nm.

[0033] Immerse the polyalkylsiloxane airgel in a xylene solution containing 2% polycarbosilane until the solution completely wets the gel, and dry the wetted polyalkylsiloxane airgel in vacuum ( The vacuum degree is less than 20Pa, and the drying temperature is 40°C) to obtain polya...

Embodiment 3

[0036] Dissolve ethyltrimethoxysilane, dimethyldiethoxysilane and cetyltrimethylammonium bromide in deionized water to obtain a transparent solution, in which ethyltrimethoxysilane, dimethyldiethoxy The mol ratio of base silane, hexadecyltrimethylammonium bromide, deionized water is 1:0.5:0.3:60; Add 3 mol / L ammoniacal liquor in above-mentioned solution and regulate solution pH value and be 11.0 and form gel, will The gel was soaked in absolute ethanol three times, each time for 12 h; the soaked gel was directly put into an oven for drying under normal pressure at a drying temperature of 120 °C for 30 h to obtain polyalkylsiloxane airgel. The average pore diameter of the prepared polyalkylsiloxane airgel was 820 nm.

[0037] Immerse the polyalkylsiloxane airgel in a xylene solution containing 3% polycarbosilane until the solution completely wets the gel, and dry the wetted polyalkylsiloxane airgel in vacuum ( The vacuum degree is less than 20Pa, and the drying temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com