Ultra-low permeability reservoir decompression and augmented injection system and preparation method

A technology for penetrating oil and systems, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as poor water injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

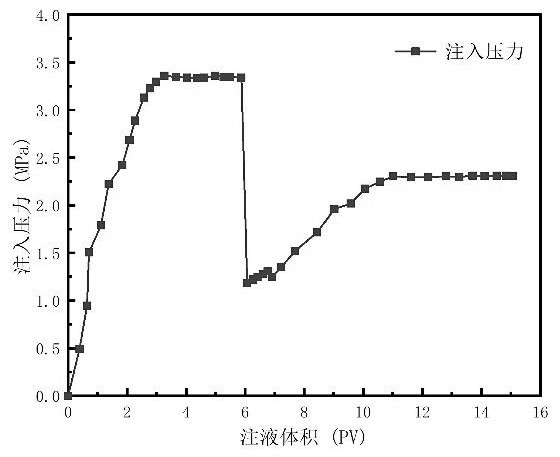

[0030] In order to overcome the problem of poor normal water injection effect in ultra-low permeability reservoirs, the present invention provides such Figure 1-5 Shown is an ultra-low permeability oil reservoir depressurization injection system and its preparation method, the invention can effectively reduce the ultra-low permeability oil reservoir water injection pressure, the depressurization rate is above 30%, the depressurization effect is remarkable, and the water injection is guaranteed to be normal .

[0031] A depressurization and injection enhancement system for ultra-low permeability reservoirs, the system is composed of the following by weight ratio:

[0032] Surfactant 0.10~0.20%

[0033] Anti-swelling agent 0.20~0.50%

[0034] Antiscale agent 0.05~0.10%

[0035] The rest is formation water.

[0036] Adopt surfactant among the present invention and can reduce interfacial tension, reduce capillary force, increase water phase permeability, reduce boundary layer...

Embodiment 2

[0039] Based on Example 1, in this example, preferably, the surfactant is stearylamine polyoxypropylene oxide ethylene ether propylene sulfonate, alkyl polyglucoside and petroleum sulfonate mixture.

[0040] Preferably, the stearylamine polyoxypropylene oxide ethylene ether propylene sulfonate, alkyl polyglucoside and petroleum sulfonate are in a mass ratio of 5:1:1.

[0041] In the present invention, the petroleum sulfonate is Shengli petroleum sulfonate, and the alkyl polyglucoside is a nonionic surfactant.

[0042] Preferably, the anti-swelling agent is one of dimethyl diallyl ammonium chloride, potassium chloride or ammonium chloride.

[0043] Preferably, the antiscalant is one of aminotrimethylene phosphonic acid, nitrogen-containing polyol phosphate or hydroxyethylidene diphosphonic acid.

[0044] Preferably, the salinity of the formation water is 9410 mg / L.

[0045] A method for preparing an ultra-low-permeability oil reservoir pressure-reducing injection system, the...

Embodiment 3

[0065] Based on the basis of Example 2, the ultra-low permeability reservoir depressurization injection system provided in this example is prepared from the following raw materials in weight percentage: 0.1% surfactant, 0.2% dimethyl diallyl chloride ammonium (DMDAAC), 0.05% aminotrimethylene phosphonic acid (ATMP), and the balance is formation water. Among them, the surfactant is octadecylamine polyoxypropylene oxide ethylene ether propylene sulfonate, alkyl polyglycoside (APG), petroleum sulfonate (SLPS) compounded according to the ratio of mass ratio 5:1:1 become.

[0066] The effect diagram of depressurization and injection increase in this embodiment is as follows figure 1 shown.

[0067] The lowest value of interfacial tension, anti-swelling rate, anti-scaling rate and pressure-reducing rate of the ultra-low permeability reservoir depressurization and augmentation injection system provided in this example were measured.

[0068] The measurement results are as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com