Environment-friendly pressure-reducing injection-increasing multi-twin active agent and preparation method thereof

An active agent and environment-friendly technology, which is applied in the composition and preparation of environment-friendly step-down injection multi-twin active agents, can solve the problems of less research and achieve the effect of reducing water injection pressure and preventing expansion and migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

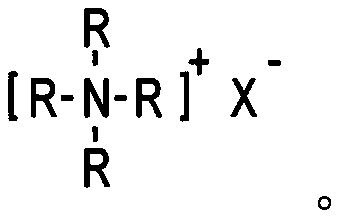

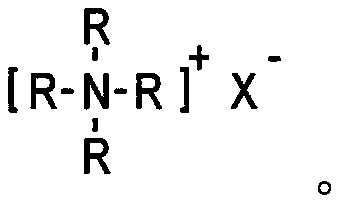

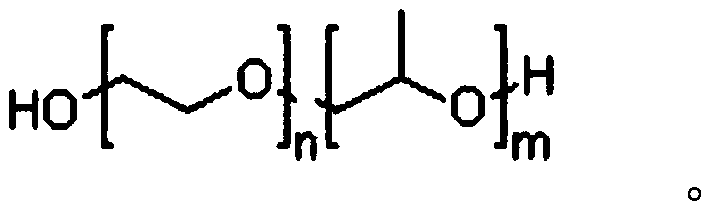

[0024] An environment-friendly multi-twin active agent for reducing pressure and increasing injection, the proportion of which is as follows:

[0025]

[0026] The quaternary ammonium salt is dodecyl benzyl ammonium chloride, the pH regulator is sodium hydroxide, and the solution cloud point regulator is dodecyl ammonium chloride.

[0027] Preparation method: first add 635Kg of water to the reactor, then add 5Kg of polyoxyethylene copolymer resin into the reactor at a speed of 105 rpm, stir for 2 hours until it is fully dissolved, then add 100Kg of dimethyl allyl ammonium chloride , 100Kg guanidine nitrate, 100Kg quaternary ammonium dodecylbenzyl ammonium chloride, 5Kg pH regulator and 5Kg cloud point regulator, and fully stirred for four hours, with a speed of 105 rpm; heated to 50-55 ° C, React for 3-5 hours, continuously stir during the reaction, and react at a constant temperature to obtain the product.

[0028] The appearance of the product is colorless or light yello...

Embodiment 2

[0030] An environment-friendly multi-twin active agent for reducing pressure and increasing injection, the proportion of which is as follows:

[0031]

[0032] The quaternary ammonium salt is dodecyl benzyl ammonium chloride, the pH regulator is sodium hydroxide, and the solution cloud point regulator is tetradecyl ammonium chloride.

[0033] Preparation method: first add 535Kg of water to the reactor, then add 5Kg of polyoxyethylene copolymer resin into the reactor at a speed of 105 rpm, stir for two hours until it is fully dissolved, then add 200Kg of dimethyl allyl ammonium chloride , 150Kg guanidine nitrate, 100Kg quaternary ammonium dodecylbenzyl ammonium chloride, 5Kg pH regulator and 5Kg cloud point regulator, the rest are water, and fully stirred for four hours, 105 rev / min of rotating speed; Warming up to 50 -55°C, react for 3-5h, stir continuously during the reaction, and react at constant temperature to obtain the product.

[0034] The appearance of the product ...

Embodiment 3

[0036] An environment-friendly multi-twin active agent for reducing pressure and increasing injection, the proportion of which is as follows:

[0037]

[0038]

[0039] The quaternary ammonium salt is cetyl benzyl ammonium chloride, the pH regulator is citric acid, and the solution cloud point regulator is dodecyl ammonium chloride, tetradecyl ammonium chloride and amine oxide.

[0040] Preparation method: first add 585Kg of water to the reactor, then add 5Kg of polyoxyethylene copolymer resin into the reactor at a speed of 105 rpm, stir for two hours until it is fully dissolved, then add 100Kg of dimethyl allyl ammonium chloride , 80Kg guanidine nitrate, 120Kg guanidine acetate, 100Kg cetyl benzyl ammonium chloride, 5Kg pH regulator and 5Kg cloud point regulator, all the other are water, and fully stirred for four hours, 105 revolutions / min of rotating speed; Warming up to 50-55°C, react for 3-5h, stir continuously during the reaction, and react at constant temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com