Membrane electrode for improving anode water management of proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, applied in fuel cells, battery electrodes, fuel cell additives, etc., can solve problems such as lower energy conversion efficiency and lower hydrogen utilization rate, and achieve lower ohmic resistance, relieve pressure, and increase resistance. The effect of water power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In Example 1, the proton exchange membrane is prepared by pouring Nafion solution into a film. First, a layer of Nafion solution is poured on a flat glass plate. Micron), and then cast a layer of S-SiO containing 5wt.% on its surface 2 The Nafion solution is dried to form a film on the anode side (the film thickness is about 25 microns).

[0025] After the membrane is completely dry, spray-coat the surface of the anode side membrane with a loading amount of 50wt.%Pt / C, Nafion, S-SiO 2 , isopropanol catalyst slurry (Pt / C, Nafion, S-SiO 2 , isopropanol in a weight ratio of 3:1:0.2:10), and finally form a catalytic layer with water-locking properties on the anode side (containing sulfonated SiO 2 about 5wt.%). Then spray a catalyst slurry composed of Pt / C, Nafion, and isopropanol on the surface of the cathode side membrane (the weight ratio of Pt / C, Nafion, and isopropanol is 3:1:10), forming a common structure on the cathode side. catalytic layer.

[0026] Select the...

Embodiment 2

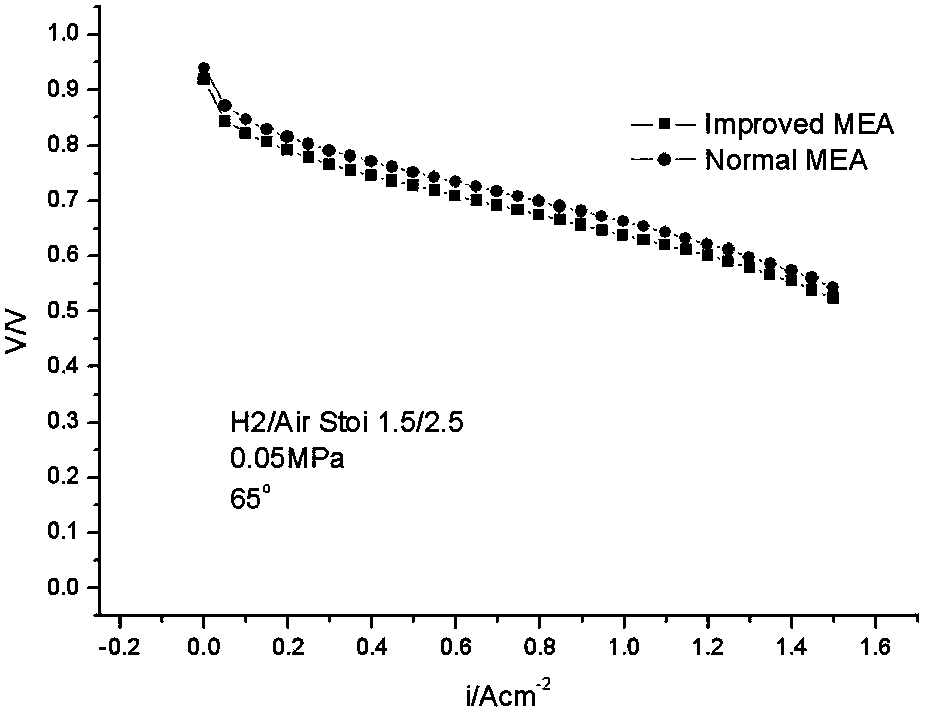

[0034] In Example 2, a layer of S-SiO containing 2wt.% is sprayed with a thickness of about 20 microns on the surface of the Nafion211 type proton exchange membrane. 2 The Nafion layer (i.e. S-SiO 2 accounted for S-SiO 2 2wt.% of the total weight of Nafion), forming an improved composite structure proton exchange membrane, and will contain S-SiO 2 side as the anode side.

[0035] Spray the catalyst slurry on the anode side surface of the above membrane, which consists of a loading of 60wt.%Pt / C, Nafion, S-SiO 2 , isopropanol composition (Pt / C, Nafion, S-SiO 2 , isopropanol mass ratio: 3:1:0.08:10), and S-SiO 2 The content is about 2wt.%. The cathode side is sprayed without SiO 2 Catalyst slurry (Pt / C, Nafion, isopropanol mass ratio is 3:1:10).

[0036] Brush the anode microporous layer slurry (nano-scale graphite powder, PTFE, water, alcohol, ammonium carbonate, the ratio is 58:40:60:400:2) on the surface of the carbon paper that has completed the hydrophobic treatment,...

Embodiment 3

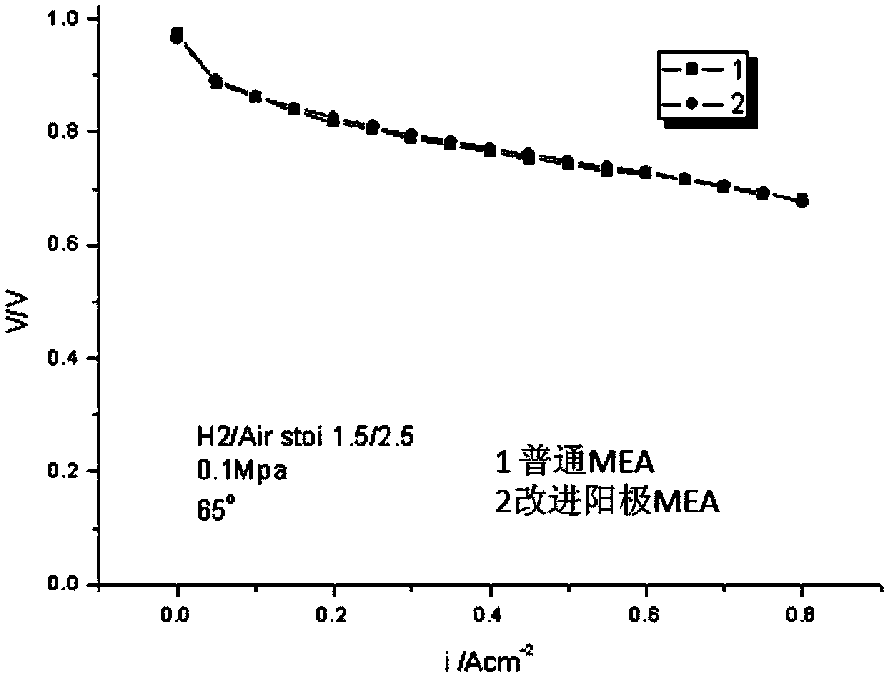

[0044] The difference from Example 2 is that the prepared proton exchange membrane anode side sulfonated SiO 2 The content is 10wt.% (ie S-SiO 2 accounted for S-SiO 2 10wt.% of the total weight of Nafion); the anode side catalytic layer contains sulfonated SiO 2 The content is about 10wt.% (Pt / C, Nafion, S-SiO 2 The mass ratio is: 3:1:0.44); the PTFE content of the microporous layer on the anode side is 50wt.%, and the ammonium oxalate is 10wt.% (nano-scale graphite powder, PTFE, ammonium carbonate, the ratio is 4:5:1). Compared the performance of membrane electrode and common membrane electrode in embodiment 3, as Figure 4 As shown, the performance of the adjusted membrane electrode did not attenuate.

[0045] The change of water output from the anode was also investigated, and the anode "dead end" mode was adopted, that is, zero gas discharge from the anode, and the water output from the anode outlet was observed. After the battery runs for 1 hour, no obvious liquid wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com