Ambient pressure drying method of silsesquioxane aerogel

A technology of silsesquioxane and atmospheric pressure drying, which is applied in the direction of airgel preparation, drying solid materials, chemical instruments and methods, etc., can solve the problems of time-consuming, incomplete surface modification and internal modification of a large number of organic solvents. Uniformity and other issues, to achieve the effect of reducing hydrophobic modification steps, facilitating large-scale production, and improving solvent replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing a silsesquioxane airgel by normal pressure drying, comprising the following steps:

[0034] 1) Precursor methyltrimethoxysilane, solvent water, surfactant, catalyst, prepare silica wet gel by sol-gel reaction.

[0035] The mass parts of each chemical component are:

[0036]

[0037] In the present invention, the precursor methyltrimethoxysilane is 15 to 25 parts, preferably 20 to 25 parts; the solvent water is 25 to 35 parts, preferably 25 to 30 parts; the surfactant is 0.2 to 0.4 parts, preferably 0.2 to 0.3 parts; 1 to 3 parts of urea, preferably 1.5 to 2.5 parts, and 0.02 to 0.07 parts of acetic acid, preferably 0.04 to 0.05 parts.

[0038] The precursor methyltrimethoxysilane, solvent water, surfactant, acetic acid and urea are mixed and stirred evenly, and the wet gel is prepared through sol-gel reaction.

[0039] The surfactant of the present invention includes cetyl trimethyl ammonium chloride or cetyl trimethyl ...

Embodiment 1

[0049] Weigh 30 parts by mass of water, add 0.04 parts by mass of acetic acid, then add 0.2 parts by mass of surfactant cetyltrimethylammonium chloride, add 1.5 parts by mass of urea, then add 20 parts by mass of precursor methyl Trimethoxysilane, mixed and stirred evenly for 1 hour for hydrolysis reaction, the temperature is 25°C.

[0050] The polymerization was catalyzed at 70°C to prepare a wet gel.

[0051] The wet gel was subjected to high temperature aging at 80°C for 24 hours.

[0052] The aged wet gel was solvent-replaced with ethanol at a temperature of 25°C for three replacements, each replacement time was 12 hours, and the mass ratio of gel to replacement ethanol was 1:3.

[0053] The gel after the solvent replacement was slowly dried at 90° C. to obtain a silsesquioxane airgel.

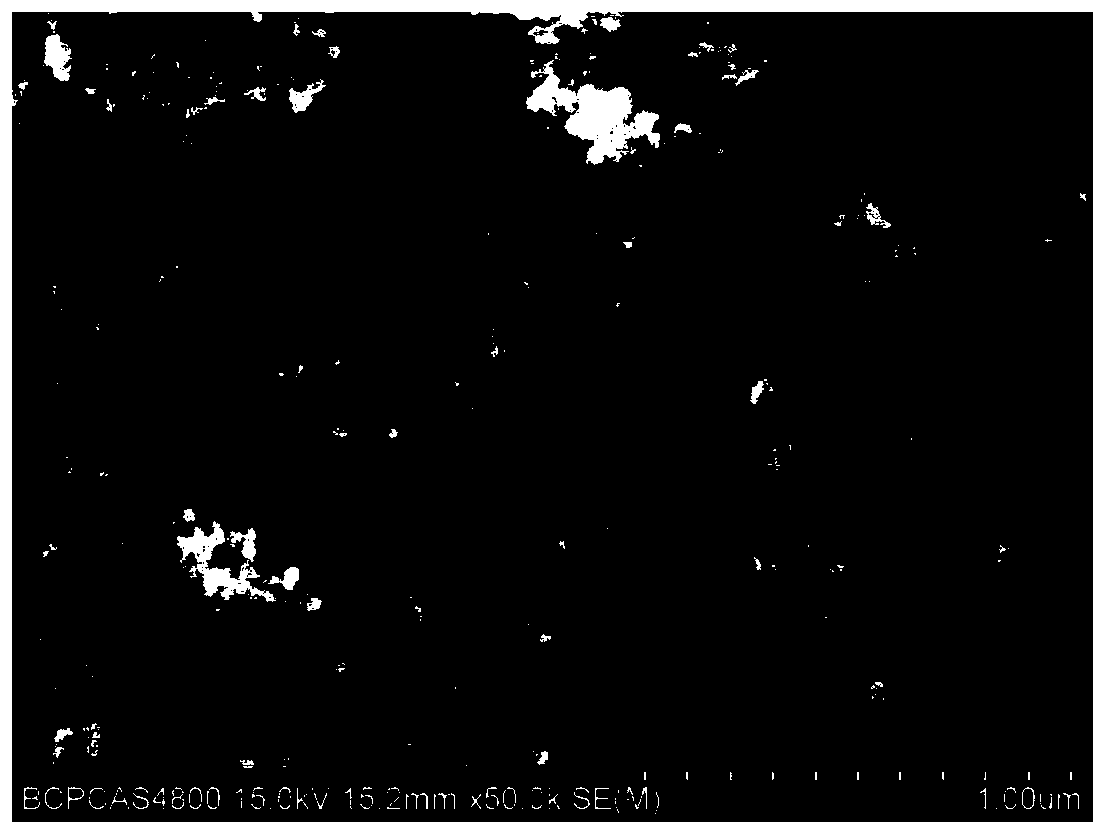

[0054] figure 1Scanning electron micrographs of the airgel prepared in this example. It can be seen that the microstructure of airgel is a three-dimensional network stacking structure ...

Embodiment 2

[0059] Weigh 30 parts by mass of water, add 0.04 parts by mass of acetic acid, then add 0.3 parts by mass of surfactant cetyltrimethylammonium chloride, add 1.5 parts by mass of urea, then add 25 parts by mass of precursor methyl Trimethoxysilane, mixed and stirred evenly for 1 hour for hydrolysis reaction, the temperature is 25°C.

[0060] The polymerization was catalyzed at 70°C to prepare a wet gel.

[0061] The wet gel was subjected to high temperature aging at 80°C for 24 hours.

[0062] The aged wet gel was solvent-substituted with ethanol at a temperature of 25°C for 3 replacements, each replacement time was 12 hours, and the mass ratio of gel to replacement ethanol was 1:3.

[0063] The gel after the solvent replacement was slowly dried at 90° C. to obtain a silsesquioxane airgel.

[0064] Figure 4 Scanning electron micrographs of the airgel prepared in this example. It can be seen that the microstructure of airgel is a three-dimensional network stacking structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com