Method for producing isopropanol by acetone hydrogenation

A technology of isopropanol and acetone, applied in the production field of isopropanol, to achieve the effects of reducing production costs, avoiding investment, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

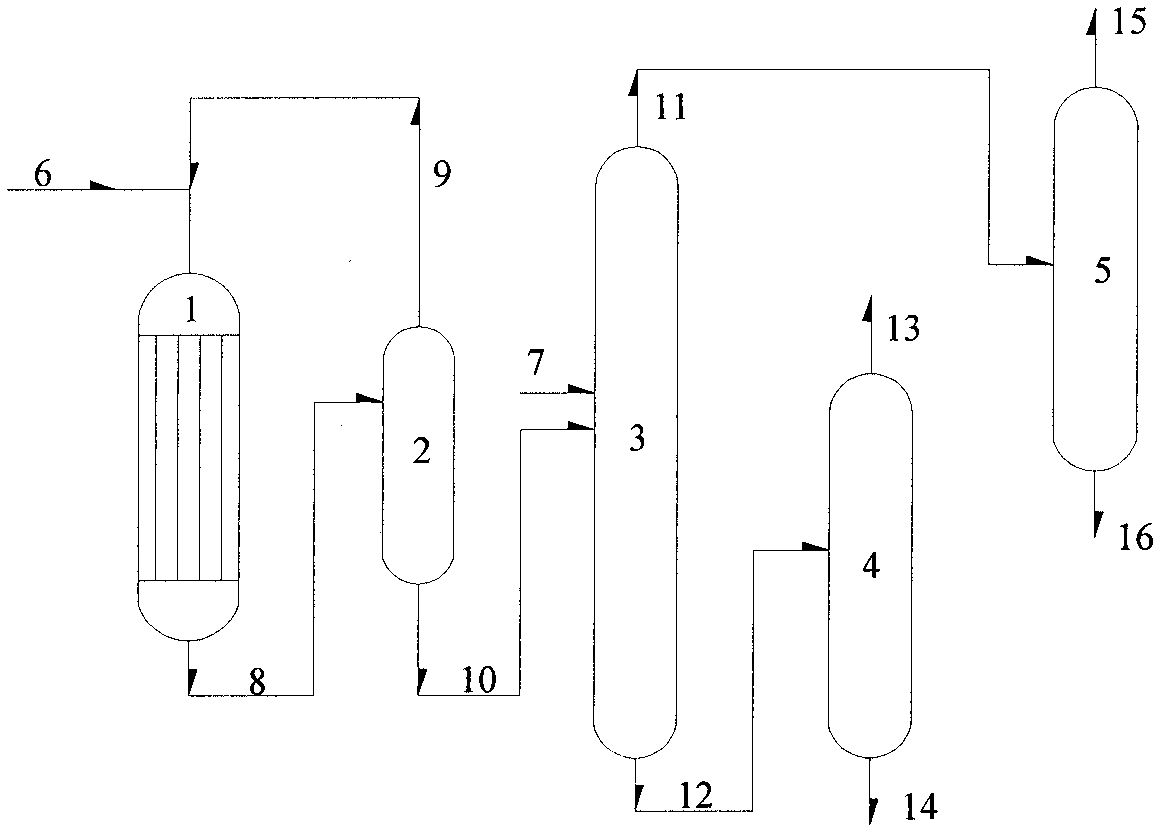

Method used

Image

Examples

Embodiment 1

[0035] Fill the reactor with 1m 3 The acetone hydrogenation catalyst BC-A-31 produced by Beijing Research Institute of Chemical Industry sends acetone and hydrogen into the reactor, and the volume space velocity of the acetone liquid phase is 0.5h -1 , the molar ratio of acetone to hydrogen is 3, the reaction temperature is 110°C, and the reaction pressure is 0.8MPa. After the hydrogenation reaction, the reaction product flows out from the outlet of the reactor, and enters the gas-liquid separation tank after condensation, and the hydrogen is produced from the top of the tank. After being compressed and recycled by the compressor, the composition of the liquid discharged from the lower part of the gas-liquid separation tank is tested, which contains 0.01% diisopropyl ether, 0.3% water (a part is brought by acetone itself, and a part is newly generated) and 0.04 % of 4-methylpentanol and other negligible traces of heavy components, the balance being isopropanol. The liquid tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com