Microarc oxidation treatment method for high strength casting rare earth magnesium alloy

A technology of micro-arc oxidation and treatment method, which is applied in the direction of anodic oxidation, etc., can solve the problems of high cost and complicated electrical parameter setting, and achieve the effect of high production efficiency, wide application value, and uniform and dense ceramic layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

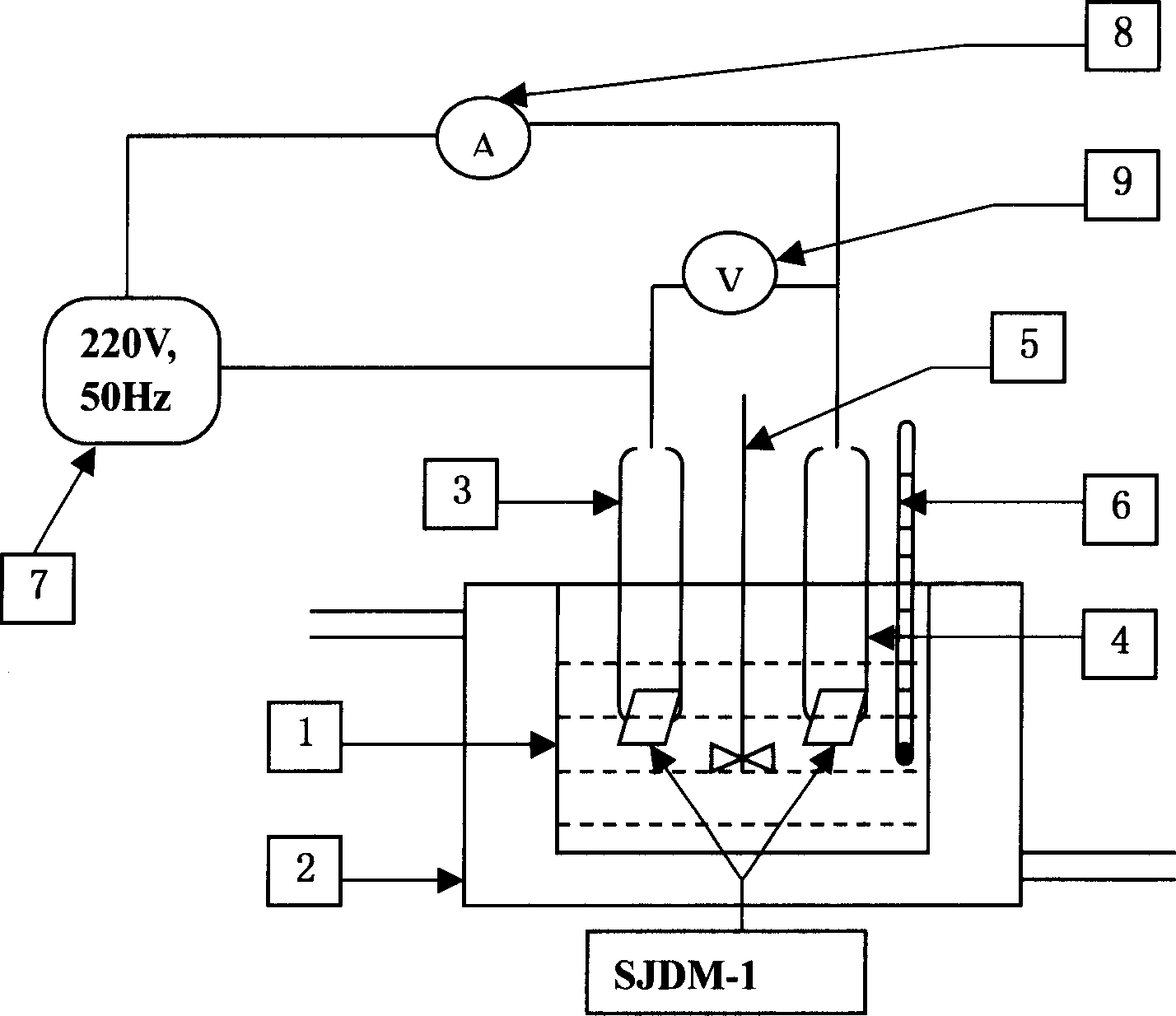

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of electrolyte solution

[0029]The components of the electrolyte include film-forming agents, auxiliary agents, additives and pH regulators; the film-forming agent sodium silicate needs to be dissolved in distilled water to a clear state, and then poured into the electrolytic cell to make its concentration 6.5g / L; the auxiliary agent , Additives and pH regulators also need to be dissolved in distilled water to a clear state, and then poured into the electrolytic cell so that the concentration of sodium fluoride is 8g / L, the concentration of glycerin is 10mL / L, and the concentration of potassium hydroxide is 8g / L.

[0030] (2) SJDM-1 pretreatment

[0031] Prepare a sodium hydroxide degreaser solution with a concentration of 100g / L. Put the SJDM-1 sample into this solution, keep it warm at 60-70°C for 15-20 minutes, rinse it with clean water, and then rinse it with distilled water; if the surface of the SJDM-1 sample is more oily, it can be hydrogenated ...

Embodiment 2

[0037] (1) Preparation of electrolyte solution

[0038] Electrolyte components include film-forming agent, auxiliary agent, additive and pH regulator; film-forming agent sodium aluminate needs to be dissolved in distilled water to a clear state, and then poured into the electrolytic cell to make the concentration 8g / L; auxiliary agent, Additives and pH regulators also need to be dissolved in distilled water to a clear state, and then poured into the electrolytic cell so that the concentration of sodium fluoride is 4g / L, the concentration of glycerin is 10mL / L, and the concentration of potassium hydroxide is 6g / L.

[0039] (2) SJDM-1 pretreatment

[0040] Prepare a sodium hydroxide degreaser solution with a concentration of 100g / L. Put the SJDM-1 sample into this solution, keep it warm at 60-70°C for 15-20 minutes, rinse it with clean water, and then rinse it with distilled water; if the surface of the SJDM-1 sample is more oily, it can be hydrogenated at 90-100°C Boil in sod...

Embodiment 3

[0046] (1) Preparation of electrolyte solution

[0047] The electrolyte components include film-forming agent, auxiliary agent, additive and pH regulator; film-forming agent sodium phosphate needs to be dissolved in distilled water to a clear state, and then poured into the electrolytic cell to make its concentration 6.5g / L; auxiliary agent, Additives and pH regulators also need to be dissolved in distilled water to a clear state, and then poured into the electrolytic cell so that the concentration of sodium fluoride is 4g / L, the concentration of glycerin is 10mL / L, and the concentration of potassium hydroxide is 4g / L.

[0048] (2) SJDM-1 pretreatment

[0049] Prepare a sodium hydroxide degreaser solution with a concentration of 100g / L. Put the SJDM-1 sample into this solution, keep it warm at 60-70°C for 15-20 minutes, rinse it with clean water, and then rinse it with distilled water; if the surface of the SJDM-1 sample is more oily, it can be hydrogenated at 90-100°C Boil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com