Method for extracting lithium from clay containing lithium

A clay and leaching solution technology, applied in the field of lithium-containing clay extraction, can solve the problem of lack of universality, and achieve the effects of avoiding a large amount of limestone, simple impurity removal, and reducing high prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

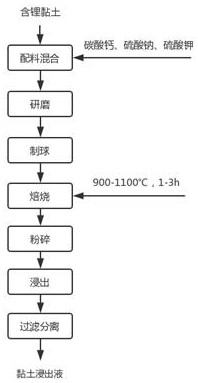

Method used

Image

Examples

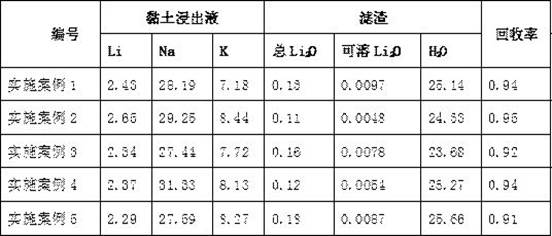

Embodiment 1

[0044]Take 500ml of water, add 40g Na2SO4, 40gK2SO4 to make a solution, then add 200g of ground clay and 40g of CaCO3, stir and filter evenly to obtain 440g of clay mixture, knead into balls manually, roast at 1000°C for 1.5h, cool and grind to P100 150um, 205 g of powder are obtained. Add 400ml of water and stir for 40min, then filter to obtain 330ml of clay extract and 184g of clay residue.

Embodiment 2

[0046] Take 500ml of water, add 60g Na2SO4, 40gK2SO4 to make a solution, then add 200g of ground clay and 40g of CaCO3, stir and filter evenly to obtain 460g of clay mixture, knead into balls manually, roast at 900°C for 2 hours, cool and grind to P100 125um to get 209g powder. Add 400ml of water and stir for 50min, then filter to obtain 350ml of clay extract and 186g of clay residue.

Embodiment 3

[0048] Take 150ml of water, add 50g Na2SO4, 40gK2SO4, then add 200g of ground clay and 40g of CaCO3 to obtain 470g of clay mixture, knead into balls, roast at 950°C for 2h, cool and grind to P100 150um to obtain 210g of powder. Add 400ml of water and stir for 40min, then filter to obtain 300ml of clay extract and 200g of clay residue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com