Copperizing solvent and preparation method thereof

A technology of copper infiltration agent and copper powder, which is applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of erosion of substrate and adhesion residue, etc. Effects of Density and Mechanical Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

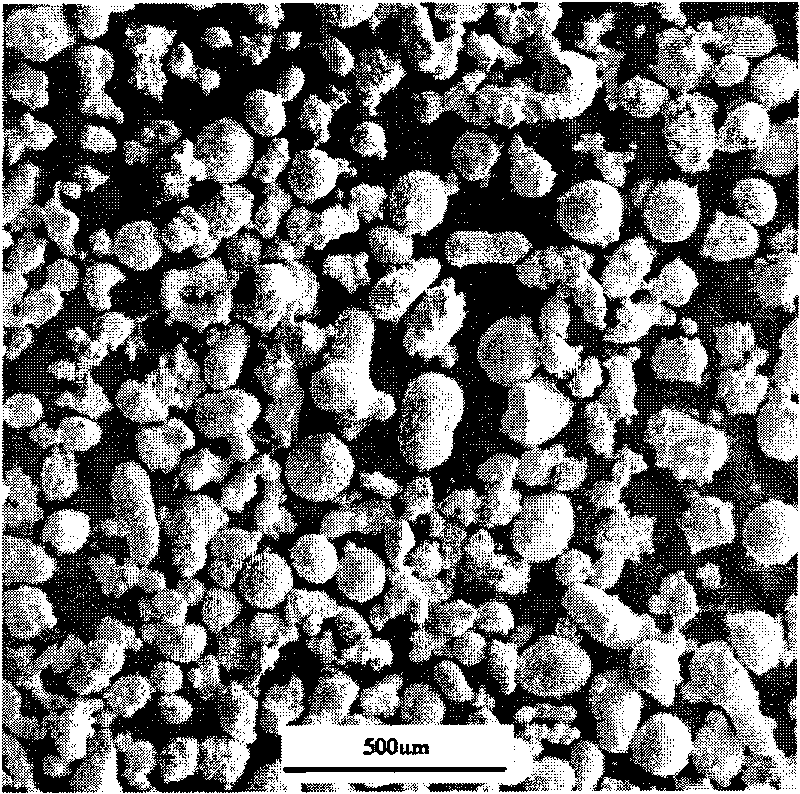

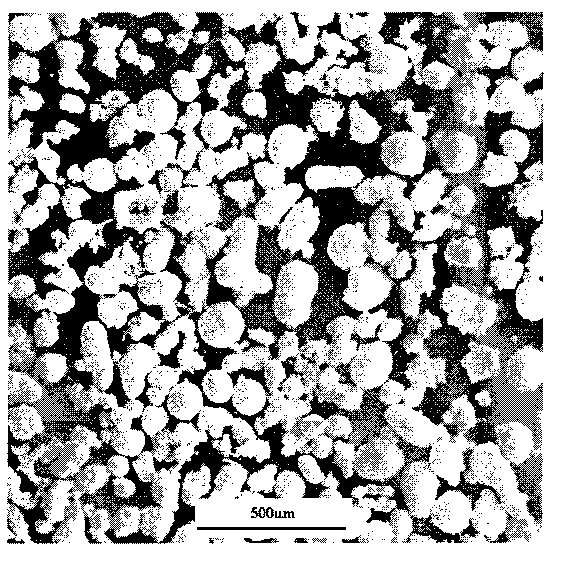

Image

Examples

Embodiment 1

[0020] A copper infiltrating agent, the component is Cu-3Fe-3Mn-3Zn, and the raw materials are electrolytic copper powder, reduced iron powder, manganese powder and CuZn30 powder.

[0021] The electrolytic copper powder has a particle size of less than 100 mesh and a bulk density of 2.0 g / cm 3 .

[0022] The reduced iron powder has a particle size of less than 150 mesh.

[0023] The manganese powder has a particle size of less than 200 mesh.

[0024] The CuZn30 powder has a particle size of less than 200 mesh.

[0025] A preparation method of copper penetration agent, the method steps are as follows:

[0026] (1) Weigh electrolytic copper powder: 84kg, reduced iron powder: 3kg, manganese powder: 3kg, CuZn30 powder: 10kg, according to the ratio of ball to material 1:20, add 5kg of alumina ceramic balls, add 0.2kg of NH 4 Cl is used as a diffusion accelerator, mixed in a mixer for 1h;

[0027] (2) After the mixing process is completed, the powder is sent to the hydrogen red...

Embodiment 2

[0031] A copper infiltrating agent, the component is Cu-2Fe-1Mn-2Cr, and the raw materials are electrolytic copper powder, electrolytic iron powder, ferromanganese powder and chromium powder.

[0032] The electrolytic copper powder has a particle size of less than 100 mesh and a bulk density of 2.0 g / cm 3 .

[0033] The electrolytic iron powder has a particle size of less than 150 mesh.

[0034] The ferromanganese powder contains 50% Mn, and the particle size is less than 200 mesh.

[0035] The chromium powder has a particle size of less than 200 mesh.

[0036] A preparation method of copper penetration agent, the method steps are as follows:

[0037] (1) Weigh electrolytic copper powder: 95kg, electrolytic iron powder: 1kg, ferromanganese powder: 2kg, chromium powder: 2kg, according to the ratio of ball to material 1:20, add 5kg of zirconia ceramic balls, add 0.15kg of ZnCl 2 As a diffusion accelerator, mix in a mixer for 1.5h;

[0038] (2) After the mixing process is co...

Embodiment 3

[0042] A copper infiltrating agent, the component is Cu-1.5Fe-1Sn-2Mn-0.5P, and the raw materials are atomized copper powder, carbonyl iron powder, CuSn10 powder, manganese powder and phosphorus iron powder.

[0043] The atomized copper powder has a bulk density of 3.5g / cm 3 , the particle size is less than 100 mesh.

[0044] The carbonyl iron powder has a particle size of less than 700 mesh.

[0045] The CuSn10 powder has a particle size of less than 200 mesh.

[0046] The manganese powder has a particle size of less than 200 mesh.

[0047] The ferrophosphorus powder contains P50%, and the particle size is less than 200 mesh.

[0048] A preparation method of copper penetration agent, the method steps are as follows:

[0049] (1) Weigh atomized copper powder: 86kg, carbonyl iron powder: 1kg, CuSn10: 10kg, manganese powder: 2kg, phosphorus iron powder: 1kg, according to the ratio of ball to material 1:20, add 5kg of stainless steel balls, add 0.25kg of NH 4 1 is used as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com